Radiator for light-emitting diode (LED) lamp

A technology of LED lamps and radiators, applied in lighting and heating equipment, semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, etc. The effect of increasing fluidity and turbulence, increasing heat transfer area, and improving heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings. It should be noted that the scope of protection of the present invention is not limited to the scope described in the embodiments.

[0023] The left-right direction of the drawings in the present invention is horizontal, and the front-back direction is vertical.

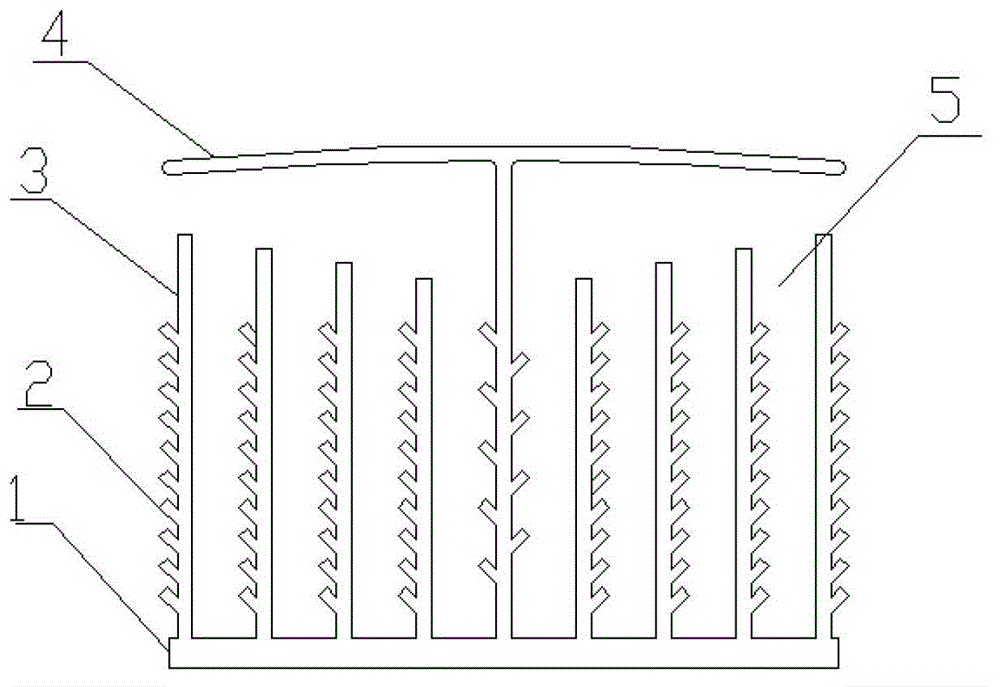

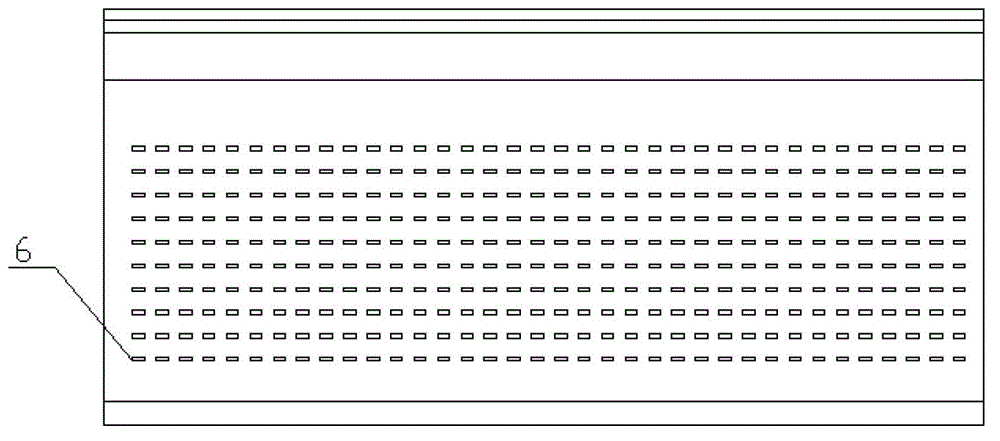

[0024] Such as figure 1 , 2 Shown, a kind of LED lamp radiator, it comprises heat dissipation substrate 1, small fin 2, large fin 3, dustproof cover 4, air flow channel 5 and window hole 6; Heat dissipation substrate 1 is square, thickness is 3 -5mm, the thickness can be changed; the large fins 3 are distributed longitudinally on the heat dissipation substrate 1 at intervals, preferably at a distance of 8-12mm, and the interval between every two large fins 3 forms an air flow channel 5; the dust cover 4 is provided Above the large fins 3, there is a distanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com