Preparation method of IGBT ceramic substrate

A technology of ceramic substrate and preparation process, which is applied in the field of ceramic material processing, can solve the problems of difficult grinding, easy warping of products, and low yield, and achieve the effects of improving production efficiency, improving production efficiency, and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

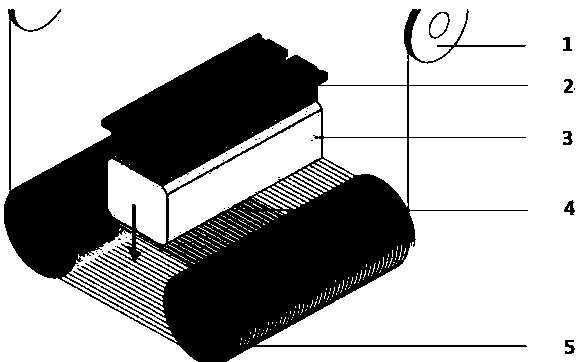

Image

Examples

Embodiment 1

[0026] Using graded alumina powder with different particle sizes as raw material, doped with 0.7% MgO and 0.125% La 2 o 3 It is used as a sintering aid, mixed with water to make a slurry with a solid content of 90%, and the alumina is prepared into a dense green body by the injection molding method, which is hot-pressed and sintered at 1650 ° C for 3 hours to obtain a dense alumina IGBT ceramic Rod with a density of 98.5%, then fix the alumina IGBT ceramic square ingot on the resin plate, cut it with a diamond wire with a diameter of 300 μm or more, cut it into a square rod with a length of 680 mm, and then fix the alumina ceramic rod on the resin plate , Put the bonded ceramic rod and resin plate into the diamond wire cutting machine for fixing, choose a diamond wire with a diameter of 100 μm, use the tangent process, cut more new wires, and less old wires, the cutting time is 120min, The cutting table speed is 1mm / min, the line speed is set at 20m / s, the cutting fluid consu...

Embodiment 2

[0028] Aluminum nitride powder with a particle size of about 1 μm is used as raw material, doped with 0.3% Y 2 o 3 and 0.125% La 2 o 3 It is used as a sintering aid, mixed with water to make a slurry with a solid content of 85%, and the aluminum nitride is prepared into a dense green body by the slip casting method, and then the green body is hot-pressed and sintered at 1700 ° C for 4 hours, and the pressure 25MPa to obtain a dense aluminum nitride IGBT ceramic rod with a density of 99.2%, then fix the aluminum nitride IGBT ceramic rod on a resin plate, cut it with a diamond wire with a diameter of 300 μm or more, and cut it into a square rod with a length of 680mm, and then Put the bonded IGBT ceramic rod and resin plate into the diamond wire cutting machine for fixing, select the diamond wire with a diameter of 90 μm, adopt the tangent process, cut more new wires and less old wires, the cutting time is 130min, The cutting table speed is 1.5mm / min, the line speed is set at...

Embodiment 3

[0030] Silicon nitride powder with a particle size of about 1 μm is used as raw material, doped with 0.1% Al 2 o 3 and 0.3% Yb 2 o 3 As a sintering aid, silicon nitride (Si 3 N 4) was prepared into a dense body, followed by GPS sintering at 1950°C and 5MPa nitrogen atmosphere for 3 hours to obtain a dense silicon nitride IGBT ceramic rod with a density of 98.7%, and then the silicon nitride IGBT ceramic rod was fixed on the resin plate, Cut with a diamond wire with a diameter of more than 300 μm, and cut it into a square rod with a length of 680 mm, then put the bonded silicon nitride IGBT ceramic rod and resin plate into a diamond wire cutting machine for fixing, and select a diamond wire with a diameter of 60 μm , using the tangent process, cutting with more new wires and less old wires, the cutting time is 130min, the cutting table speed is 0.5mm / min, the line speed is set at 10m / s, the cutting fluid consumption is 2L / knife, and the final piece is produced 2000 Silicon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com