A room temperature air-breathing composite material and its products

A composite material and normal temperature technology, which is applied in gas treatment, other chemical processes, separation methods, etc., can solve the problems of poor oxygen absorption capacity and limited catalytic effect of getter materials, and achieve high water absorption rate, human body and environment friendly, gas The effect of balancing depression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

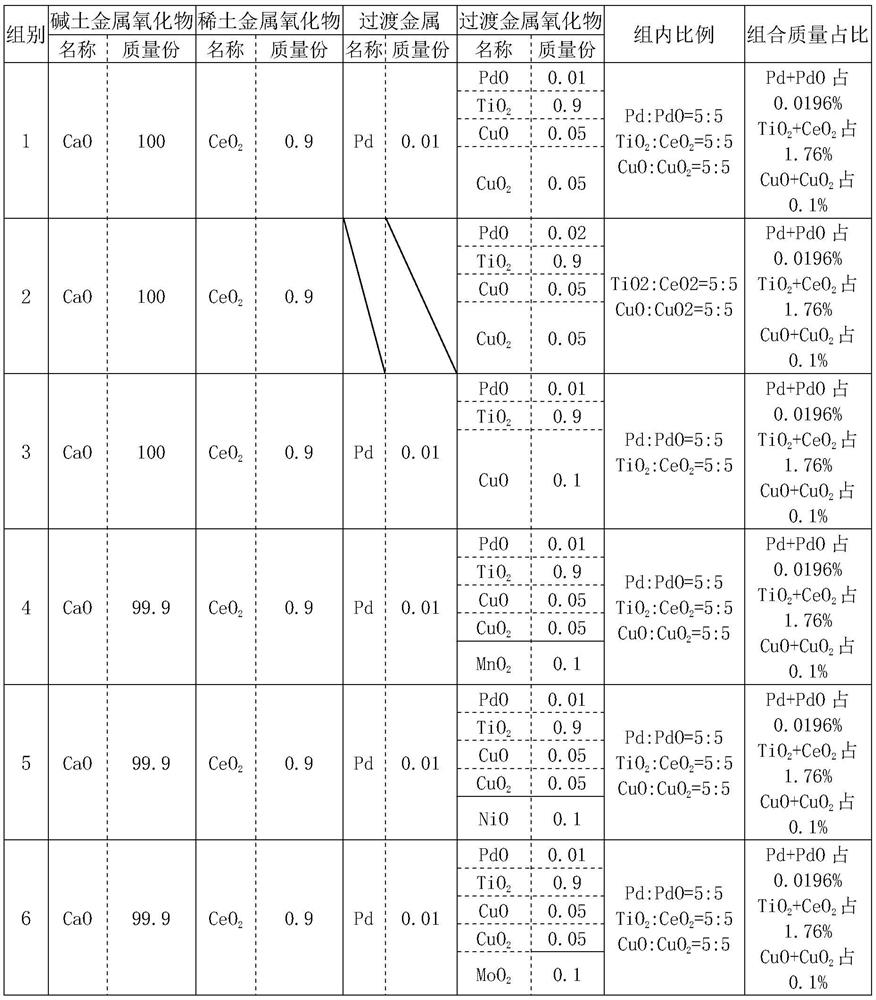

Embodiment 1

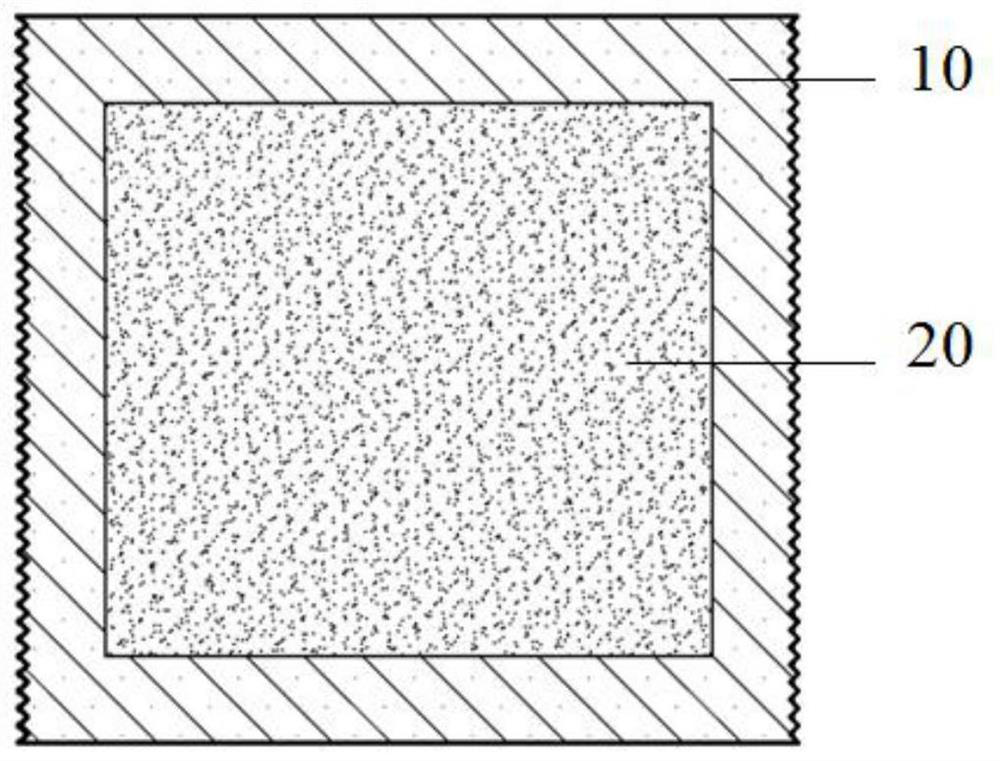

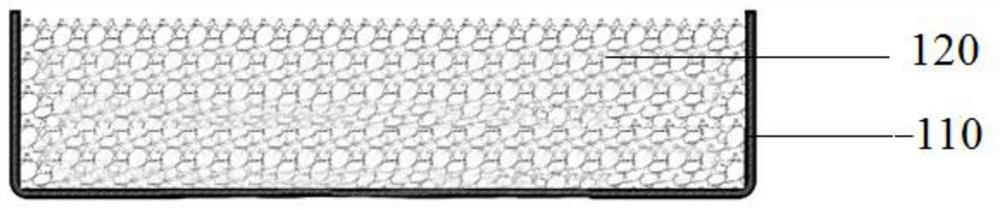

[0027] Preparation of 1# getter product comprising the room temperature getter composite material of the present invention.

[0028] Use a precision balance to weigh 100 g of commercial calcium oxide powder with a purity of 96% and a particle size of 325 mesh, 0.30 g of copper nitrate powder, 1.30 g of titanic acid, 2.25 g of cerium nitrate, and 0.044 g of palladium nitrate powder; all the aforementioned ingredients are poured into a 400 ml beaker, Add 300 ml of deionized water, stir with a magnetic stirrer for 30 min at 70 °C; dry the mixed solution in an oven at a baking temperature of 120 °C and a baking time of 108 h; place the dried mixture in an atmosphere furnace under nitrogen protection Calcining at 600°C for 2h and 1050°C for 1h; grinding the calcined product into powder to obtain a normal temperature gettering composite powder according to the present invention, the mass ratio of each component is about calcium oxide: (copper oxide + cuprous oxide) : titanium dioxid...

Embodiment 2

[0030] Preparation of 2# absorbent article comprising the room temperature inhalation composite material of the present invention.

[0031] Use a precision balance to weigh 100 g of commercial calcium oxide powder with a purity of 96% and a particle size of 325 mesh, 0.30 g of copper nitrate powder, 1.30 g of titanic acid, 2.25 g of cerium nitrate, and 0.044 g of palladium nitrate powder; all the aforementioned ingredients are poured into a 400 ml beaker, Add 300 ml of deionized water, stir with a magnetic stirrer for 30 min at 70 °C; dry the mixed solution in an oven at a baking temperature of 120 °C and a baking time of 108 h; place the dried mixture in an atmosphere furnace under nitrogen protection calcined at 300°C for 2h and 1050°C for 1h; grind the calcined product into powder to obtain a normal temperature gettering composite powder according to the present invention, the mass ratio of each component is about calcium oxide: (copper oxide + cuprous oxide) : titanium dio...

Embodiment 3

[0033] Preparation of 3# getter products comprising the room temperature getter composite material of the present invention.

[0034] Use a precision balance to weigh 100 g of commercial calcium oxide powder with a purity of 96% and a particle size of 325 mesh, 0.30 g of copper nitrate powder, 1.30 g of titanic acid, 2.25 g of cerium nitrate, and 0.044 g of palladium nitrate powder; all the aforementioned ingredients are poured into a 400 ml beaker, Add 300 ml of deionized water, stir with a magnetic stirrer for 30 min at 70 °C; dry the mixed solution in an oven at a baking temperature of 120 °C and a baking time of 108 h; place the dried mixture in an atmosphere furnace under nitrogen protection calcined at 600° C. for 2 hours; the calcined product is ground into powder to obtain a normal temperature gettering composite material powder according to the present invention, and the mass ratio of each component is about calcium oxide: copper oxide: titanium dioxide: cerium oxide: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com