High-conductivity solid electrolyte prepared by sol-gel method

A solid electrolyte, sol-gel technology, applied in the field of high-conductivity solid electrolytes, can solve the problems of large grain boundary resistance of solid electrolytes, difficult recycling of impurities, heat treatment temperature sensitivity, etc., and achieves low heat treatment temperature sensitivity, high density, The effect of low grain boundary resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

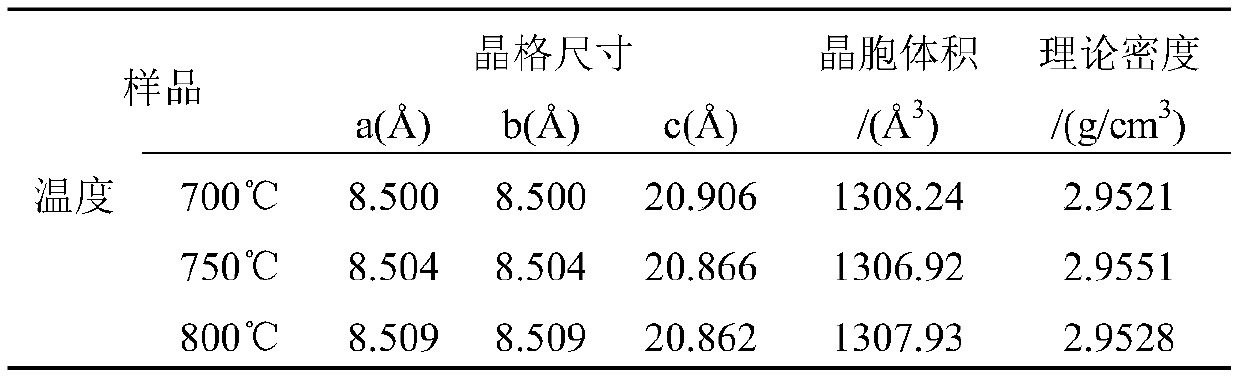

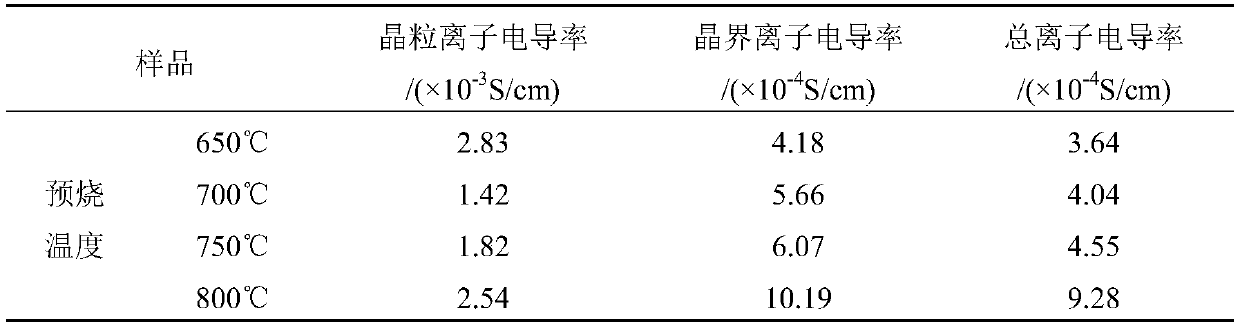

[0042] A high-conductivity solid electrolyte prepared by a sol-gel method, using lithium nitrate as a dopant, using lithium titanium aluminum phosphate (LATP) as the main material, and using a sol-gel method to embed the dopant into lithium titanium aluminum phosphate (LATP) ) in the skeleton to form a NASICON structure;

[0043] The preparation method of the high-conductivity solid electrolyte comprises the steps of:

[0044] S1 preparation solution A: according to Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 Weigh tetrabutyl titanate, add ammonia water and filter and wash several times, then slowly add tetrabutyl titanate to 0.4mol / L citric acid aqueous solution, heat and magnetically stir for 6h, and form a clear liquid, namely Get solution A;

[0045] S2 preparation solution B: according to Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 Stoichiometric ratio, weigh lithium acetate, ammonium dihydrogen phosphate in turn, and weigh citric acid according to the molar ratio of citric acid and met...

Embodiment 2

[0052] A high-conductivity solid electrolyte, with germanium oxide as the dopant and lithium aluminum titanium phosphate (LATP) as the main material, the dopant is embedded in the lithium aluminum titanium phosphate (LATP) skeleton by the sol-gel method to form NASICON Structure; the structural formula after doping is Li 1.3 Al 0.3 Ti 1.6 Ge 0.1 (PO 4 ) 3 ;

[0053] The preparation method of the high-conductivity solid electrolyte comprises the steps of:

[0054] S1 preparation solution A: according to Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 Weigh tetrabutyl titanate, add ammonia water and filter and wash several times, then slowly add tetrabutyl titanate to 0.4mol / L citric acid aqueous solution, heat and magnetically stir for 6h, and form a clear liquid, namely Get solution A;

[0055] S2 preparation solution B: according to Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 The stoichiometric ratio of lithium nitrate, ammonium dihydrogen phosphate was weighed sequentially, and citric ac...

Embodiment 3

[0062] A high-conductivity solid electrolyte prepared by a sol-gel method, using ethyl orthosilicate as a dopant, using lithium titanium aluminum phosphate (LATP) as the main material, and using a sol-gel method to embed the dopant into titanium aluminum phosphate In the lithium (LATP) skeleton, a NASICON structure is formed; the structural formula after doping is Li 1.3 Al 0.3 Ti 1.6 Si 0.1 (PO 4 ) 3 ;

[0063] The preparation method of the high-conductivity solid electrolyte comprises the steps of:

[0064] S1 preparation solution A: according to Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 Weigh tetrabutyl titanate, add ammonia water and filter and wash several times, then slowly add tetrabutyl titanate to 0.4mol / L citric acid aqueous solution, heat and magnetically stir for 6h, and form a clear liquid, namely Get solution A;

[0065] S2 preparation solution B: according to Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 Stoichiometric ratio, weigh lithium acetate, ammonium dihydrogen ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com