Preparation method of high-temperature-resistant polyurea elastic flame-retardant waterproof coating

A waterproof coating and high temperature resistant technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems of low cost, water resistance of concrete surface, easy pollution, etc., and shorten the construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

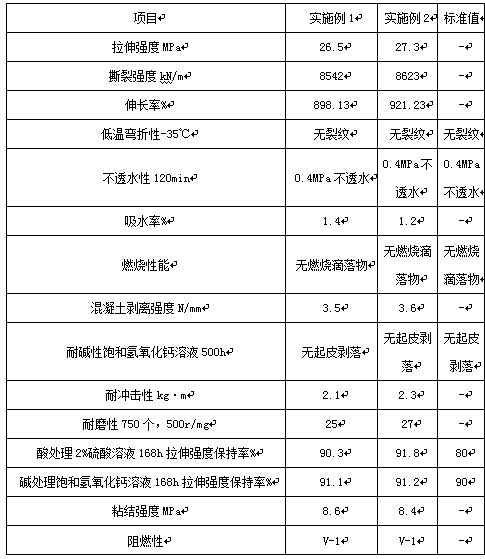

Embodiment 1

[0033] A preparation method of high temperature resistant polyurea elastic flame retardant waterproof coating, comprising the following steps:

[0034] 1. Preparation of grafting solution:

[0035] Weigh 25 parts by weight of isooctyl acrylate and 1.5 parts by weight of organosiloxane coupling agent and dissolve them in 85 parts of solvent to obtain a grafting solution; the organosiloxane coupling agent is β-(3,4-ring Oxycyclohexyl) ethyltrimethoxysilane, the solvent is chloroform;

[0036] Second, the preparation of polyurethane emulsion solution:

[0037] After vacuum dehydration of 25 parts of hydroxyl-terminated polybutadiene liquid rubber with a number average molecular weight of 2500, add 24 parts of lysine triisocyanate and 42 parts of methyl ethyl ketone, mix well, react at 80°C for 1 hour, cool to room temperature, drop Dilute 0.5 part of bismorpholino diethyl ether with 7 parts of butanone, control the rate of addition, after the dropwise addition for 10 minutes, k...

Embodiment 2

[0054] A preparation method of high temperature resistant polyurea elastic flame retardant waterproof coating, comprising the following steps:

[0055] 1. Preparation of grafting solution:

[0056] Weigh 35 parts by weight of 2-hydroxyethyl methacrylate and 3.0 parts by weight of organosiloxane coupling agent and dissolve them in 95 parts of solvent to obtain a grafting solution; the organosiloxane coupling agent is γ-isocyanate Propyltrimethoxysilane, the solvent is tetrahydrofuran;

[0057] Second, the preparation of polyurethane emulsion solution:

[0058] After vacuum dehydration of 33 parts of hydroxyl-terminated polybutadiene liquid rubber with a number average molecular weight of 5000, add 26 parts of lysine triisocyanate and 53 parts of methyl ethyl ketone, mix well, react at 85°C for 3 hours, cool to room temperature, drop Dilute 1 part of bismorpholinyl diethyl ether with 7 parts of butanone, control the rate of addition, after the dropwise addition for 20 minutes,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com