Preparation method of fluorine functional monomer modified soap-free emulsion polymer for polymer cement

A technology of soap-free emulsion and functional monomer, applied in the field of preparation of soap-free emulsion polymer modified with fluorine functional monomer for polymer cement, to achieve reliable reaction, mild reaction conditions, good heat transfer and temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

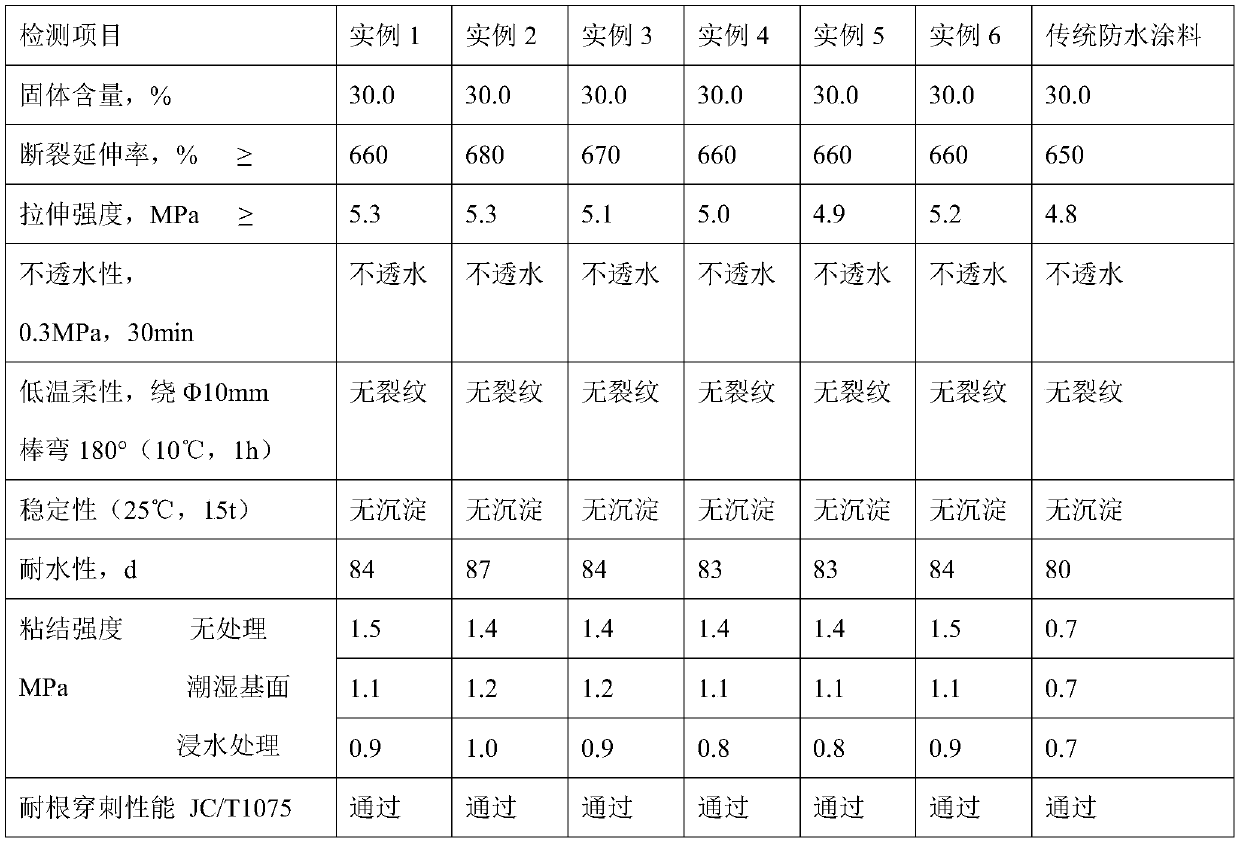

Examples

example 1

[0047] A preparation method of a soap-free emulsion polymer modified with a fluorine functional monomer for polymer cement, which is mainly prepared from the following components:

[0048] 4-(ethyleneoxy)-1-butanol: 14 parts

[0049] Composition with a mass ratio of allyl alcohol to methacryl alcohol of 9:4: 13 parts

[0050] Sodium methacrylate: 0.7 parts

[0051] The composition of azobisisobutyronitrile and tert-butyl peroxy tert-butyl peroxyvalerate in a mass ratio of 5:3: 0.4 parts

[0052] Dicyclohexyl peroxydicarbonate: 3.4 parts

[0053] Butyl acrylate: 8 parts

[0054] Methacryloyloxyethyl hexahydrophthalate monoester: 227 parts

[0055] The composition of tris(2-hydroxyethyl)isocyanurate triacrylate and ethylene glycol dimethacrylate with a mass ratio of 1:1: 5.9 parts

[0056] Perfluorooctyl ethyl acrylate: 8 parts

[0057] Sodium methoxide: 6.6 parts

[0058] Sodium bicarbonate: 13 parts

[0059] The total mass parts is 1000, and the remainder is water.

...

example 2

[0065] A preparation method of a soap-free emulsion polymer modified with a fluorine functional monomer for polymer cement, which is mainly prepared from the following components:

[0066] Prenol: 10 parts

[0067] Composition with a mass ratio of allyl alcohol to methacryl alcohol of 9:4: 16 parts

[0068] Sodium methacrylate: 0.6 parts

[0069] Composition with azobisisobutyronitrile and tert-butyl peroxy tert-butyl peroxyvalerate at a mass ratio of 5:3: 0.6 parts

[0070] Composition with a mass ratio of diisopropyl peroxydicarbonate to dicyclohexyl peroxydicarbonate of 3:1: 4.2 parts

[0071] Composition with a mass ratio of hydroxypropyl acrylate to diethyl maleate of 2:3: 10 parts

[0072] Composition with a mass ratio of 2-propylheptyl acrylate to methacryloyloxyethyl phthalate monoester at a mass ratio of 5:2: 226 parts

[0073] The composition of tris(2-hydroxyethyl)isocyanurate triacrylate and ethylene glycol dimethacrylate with a mass ratio of 1:1: 3.8 parts

...

example 3

[0083] A preparation method of a soap-free emulsion polymer modified with a fluorine functional monomer for polymer cement, which is mainly prepared from the following components:

[0084] 4-(ethyleneoxy)-1-butanol: 12 parts

[0085] Propyl alcohol: 17 parts

[0086] Sodium methacrylate: 0.8 parts

[0087] Dibenzoyl peroxide: 0.7 parts

[0088] Composition with a mass ratio of diisopropyl peroxydicarbonate to dicyclohexyl peroxydicarbonate of 3:1: 3.5 parts

[0089] Butyl acrylate: 12 parts

[0090] Composition of 2-propylheptyl acrylate and methacryloyloxyethyl phthalic acid monoester with a mass ratio of 5:2: 230 parts

[0091] Ethylene glycol dimethacrylate: 4.5 parts

[0092] Perfluorooctyl ethyl acrylate: 6 parts

[0093] Sodium methoxide: 3.5 parts

[0094] Potassium carbonate: 10 parts

[0095] The total mass parts is 1000, and the remainder is water.

[0096] 1) Mix 200 parts of water, 12 parts of 4-(ethyleneoxy)-1-butanol, 0.8 parts of sodium methacrylate, 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com