Waterborne polyurethane dispersion and preparation method and application thereof

A technology of water-based polyurethane and polyurethane prepolymer, applied in polyurea/polyurethane coatings, application, animal husbandry, etc., can solve the problems of poor water resistance and stain resistance, and achieve remarkable stain resistance and gloss The effect of high temperature and low VOC emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

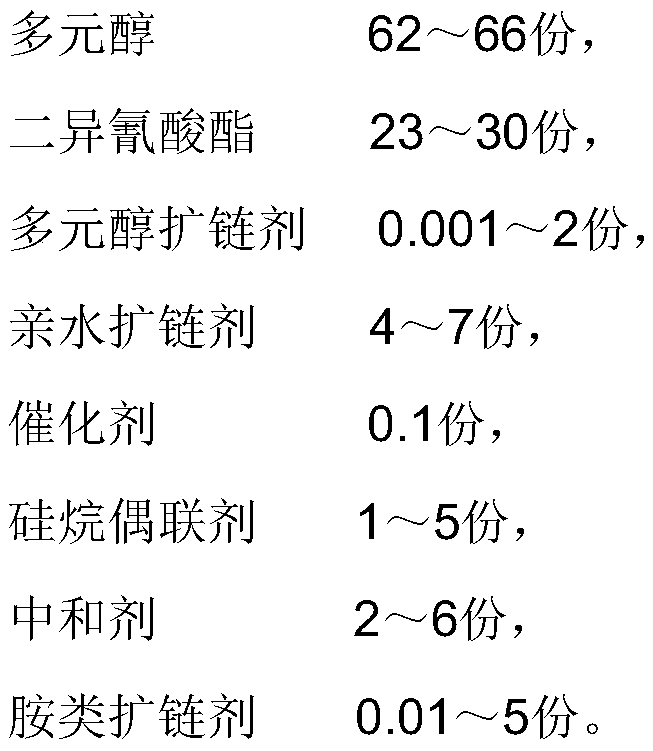

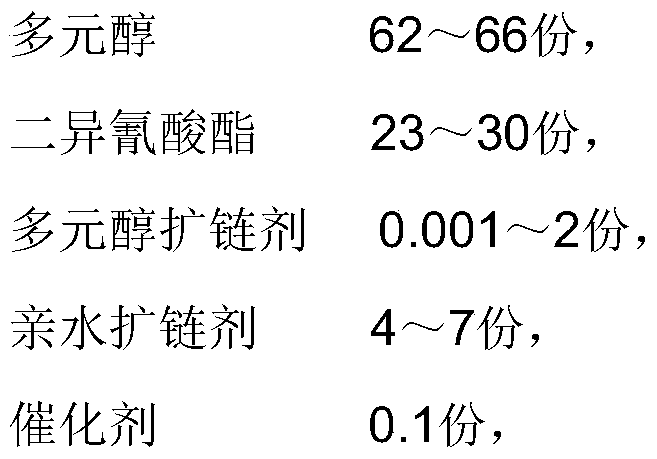

[0025] A kind of aqueous polyurethane dispersion, its preparation method comprises the following steps (each raw material consumption is by mass parts):

[0026] Step 1. Preparation of polyurethane prepolymer containing hydrophilic monomer: react 62-66 parts of polyol and 23-30 parts of diisocyanate at 80-90°C for 2 hours, then add 0.001-2 parts of polyol to expand Chain agent, 4-7 parts of hydrophilic chain extender, 0.1 part of catalyst and 10 parts of acetone, and react at 80-85 °C for 2-4 hours, then add 1-5 parts of silane coupling agent for reaction, Until the content of -NCO reaches 1-3%, the polyurethane prepolymer is prepared.

[0027] Step 2, neutralization reaction: cool down the polyurethane prepolymer to 25-45°C, add acetone accounting for 40% of the total mass of the polyurethane prepolymer to the polyurethane prepolymer, and then Under the action of shearing, add 2-6 parts of neutralizing agent and react for 3-5 minutes to obtain a neutralized reaction liquid. ...

Embodiment approach

[0030] (1) The polyhydric alcohol adopts polyadipate-1,3-butylene glycol ester diol, polyadipate-2-methyl-1,3-butylene glycol ester diol, polyadipate-1 , 4 butanediol ester diol, polyethylene adipate diol, polytrimethylene adipate diol, polyethylene adipate butylene glycol ester diol, polycaprolactone diol , at least one of polycarbonate diol, polydimethylsiloxane, polypropylene glycol, and double-terminated hydroxyl polyether modified silicone oil, and the number average molecular weight of the polyol is 1000-4000.

[0031] (2) The diisocyanate is at least one of isophorone diisocyanate, diphenylmethane diisocyanate, toluene diisocyanate, and 1,6-hexamethylene diisocyanate.

[0032] (3) The polyol chain extender is at least one of trimethylolpropane, diethylene glycol, 1,4-butanediol, and 1,4-cyclohexanedimethanol.

[0033] (4) The hydrophilic chain extender adopts at least one of dimethylolbutyric acid, dimethylolpropionic acid (DMPA), and A95 (sodium ethylenediamine sulfon...

Embodiment 1

[0047] A kind of aqueous polyurethane dispersion, its preparation method comprises the following steps (each raw material consumption is by mass parts):

[0048] Step 1a. Add 60 parts of polycarbonate diol and 5 parts of polydimethylsiloxane into a three-necked bottle, vacuum dehydrate at 120°C for 2 hours, cool down to 80-85°C, and add 28 parts of isophorone Diisocyanate, keep the temperature at 80-85°C, react for 2h; then add 1 part of trimethylolpropane, 6 parts of DMPA, 0.1 part of organic bismuth catalyst and 10 parts of acetone, keep the temperature at 80-85°C, react for 3h, then add Add 5 parts of γ-aminopropyltriethoxysilane and stir for 20 minutes until the content of -NCO reaches 1-3%, so as to prepare a polyurethane prepolymer.

[0049] Step 2a, cooling the polyurethane prepolymer to 40-45°C, adding 10 parts of acetone to the polyurethane prepolymer to reduce the viscosity of the polyurethane prepolymer, and then adding 5 parts of triethylamine, and reacted for 3 to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com