Method for rapidly wetting carbon fibers in ceramic matrix composite material by taking Fe as active element

A technology of composite materials and active elements, applied in the direction of welding/cutting media/materials, welding media, manufacturing tools, etc., can solve problems such as high brittleness, poor brazability, and poor high temperature resistance, and achieve improved heat resistance temperature, The effect of reducing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

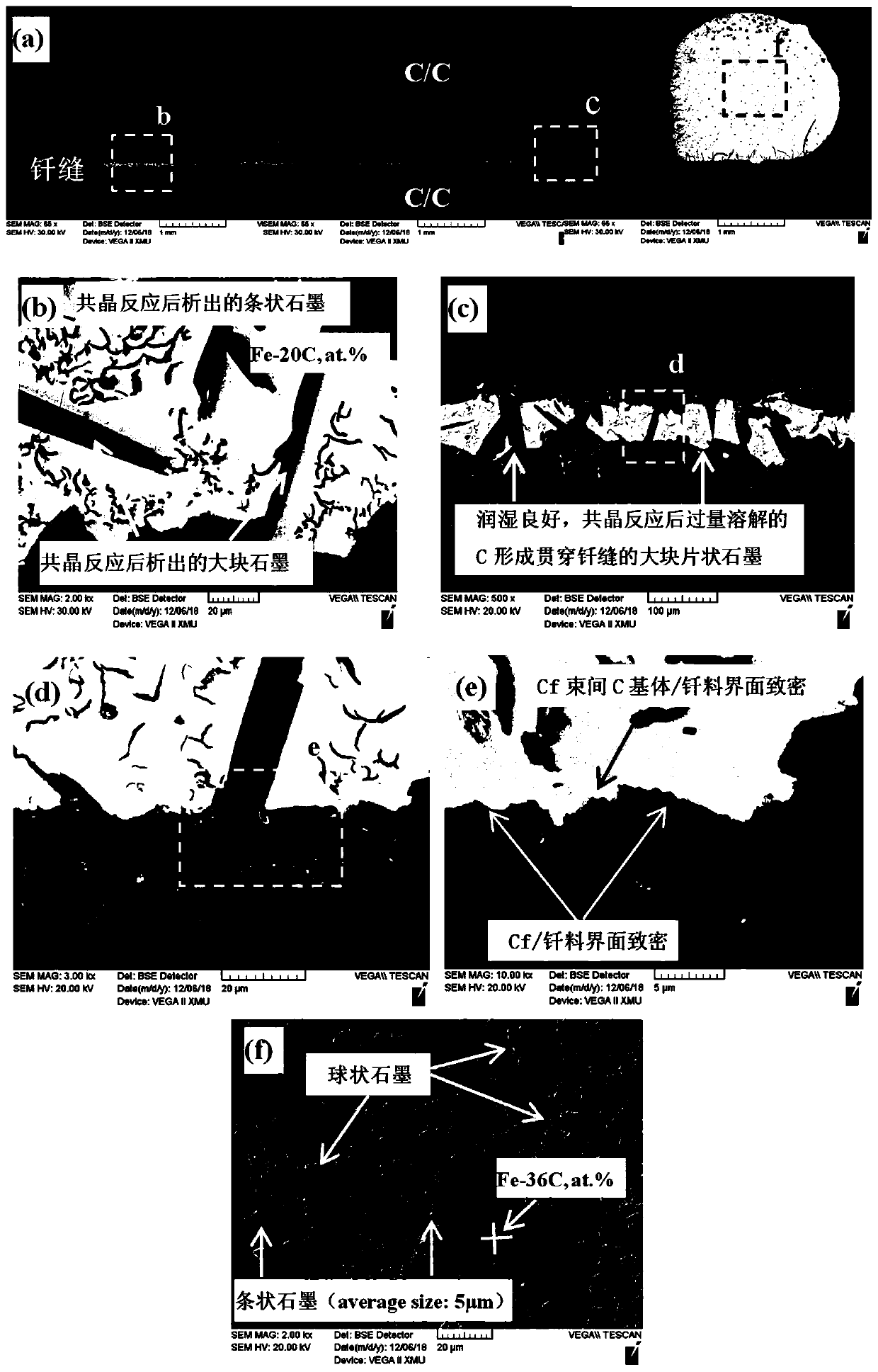

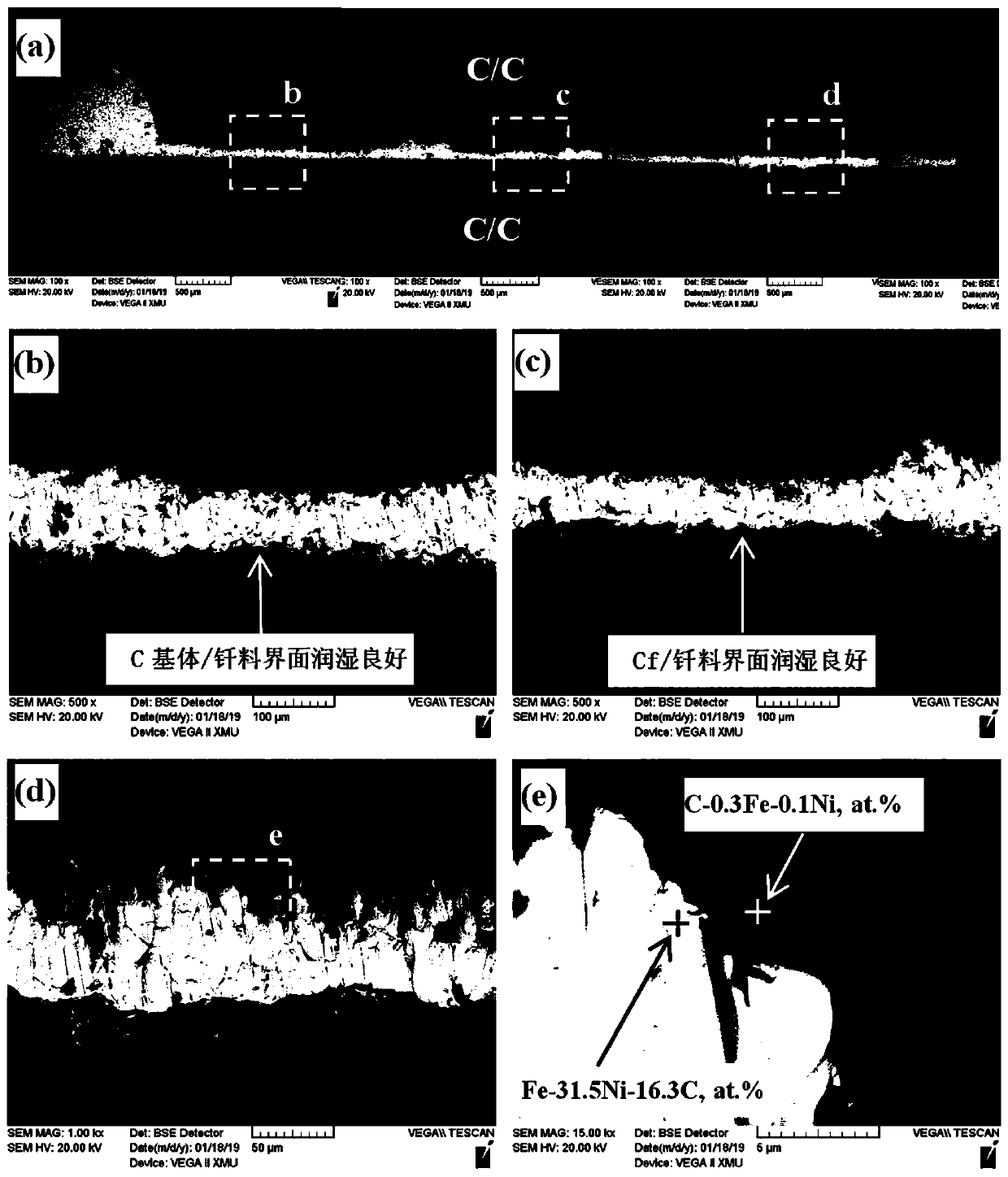

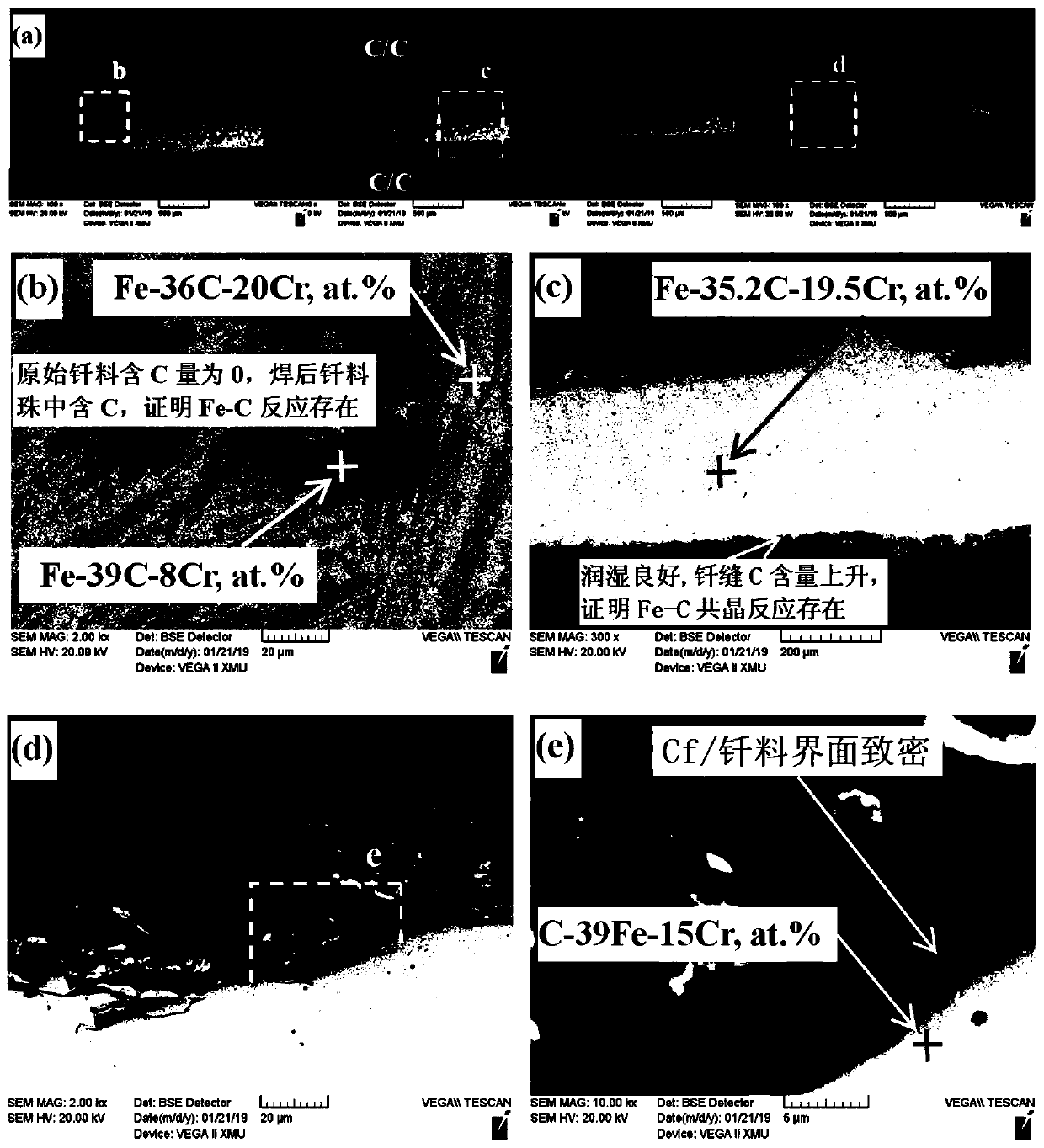

[0082] For traditional Ti-containing silver-based and copper-based active solders for brazing C f / C and C f / SiC and other ceramic matrix composite materials have the problem of low joint heat resistance temperature, and Ni-based commercial solder is used for brazing C f / C and C f / SiC and other ceramic matrix composite materials have the problem that the brittleness is large and need to be kept warm for a long time. The present invention is based on carbon fiber (C f ) In the brazing of reinforced ceramic matrix composites (CMC), it is proposed that the eutectic reaction between the weak carbide-forming element Fe, the non-carbide-forming element Ni or the medium-strength carbide-forming element Cr and the carbon fiber, at a higher temperature ( Above 1154℃) quickly achieves the wetting of carbon fibers in carbon fiber reinforced ceramic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com