Bone repair material constructed by 3D printing, preparation method and application thereof

A 3D printing and bone repair technology, applied in the field of biomedical engineering materials, can solve the problems of easy collapse of bone materials, poor material stability, high printing temperature, and achieve the effect of ensuring mechanical strength and promoting osseointegration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

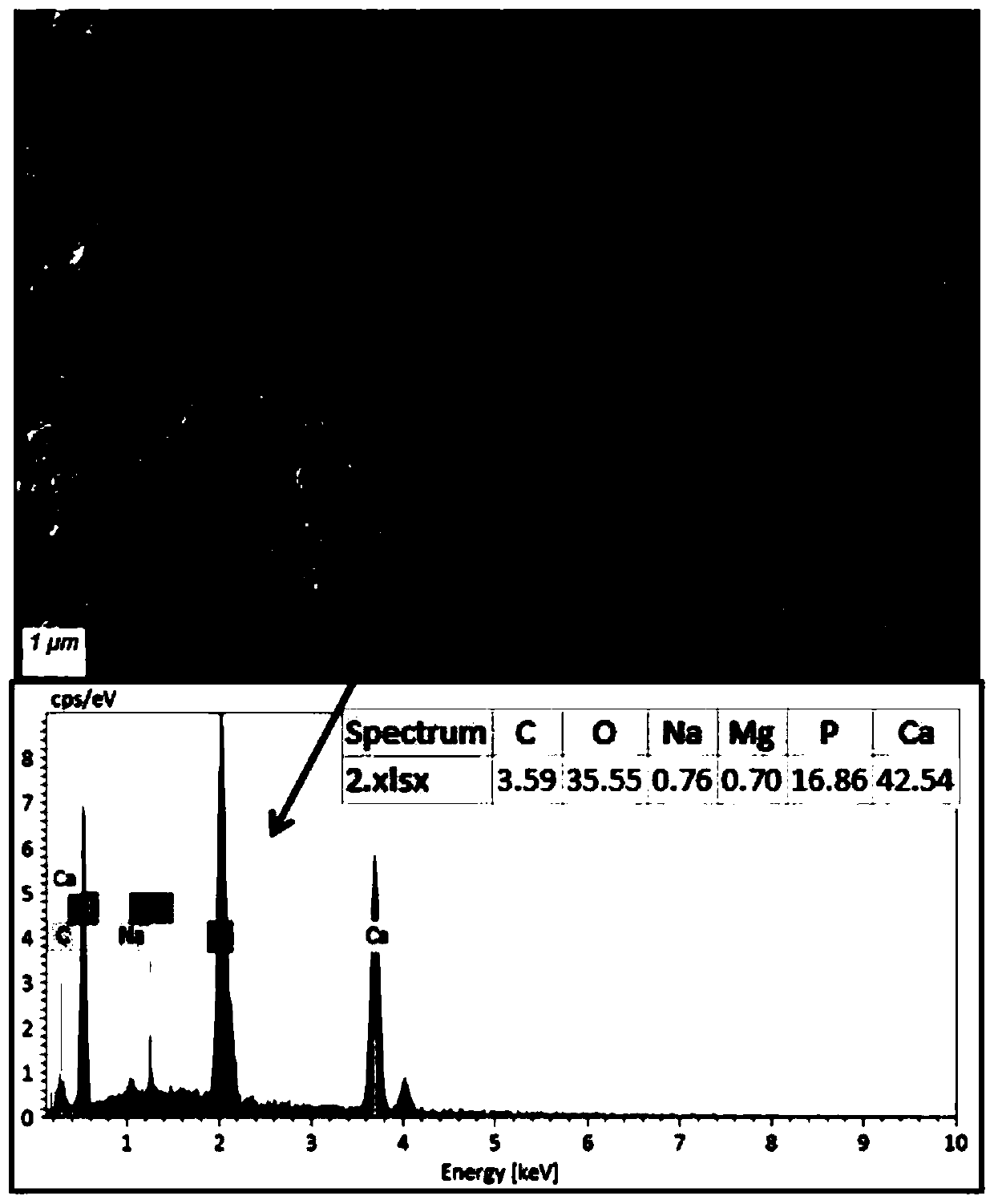

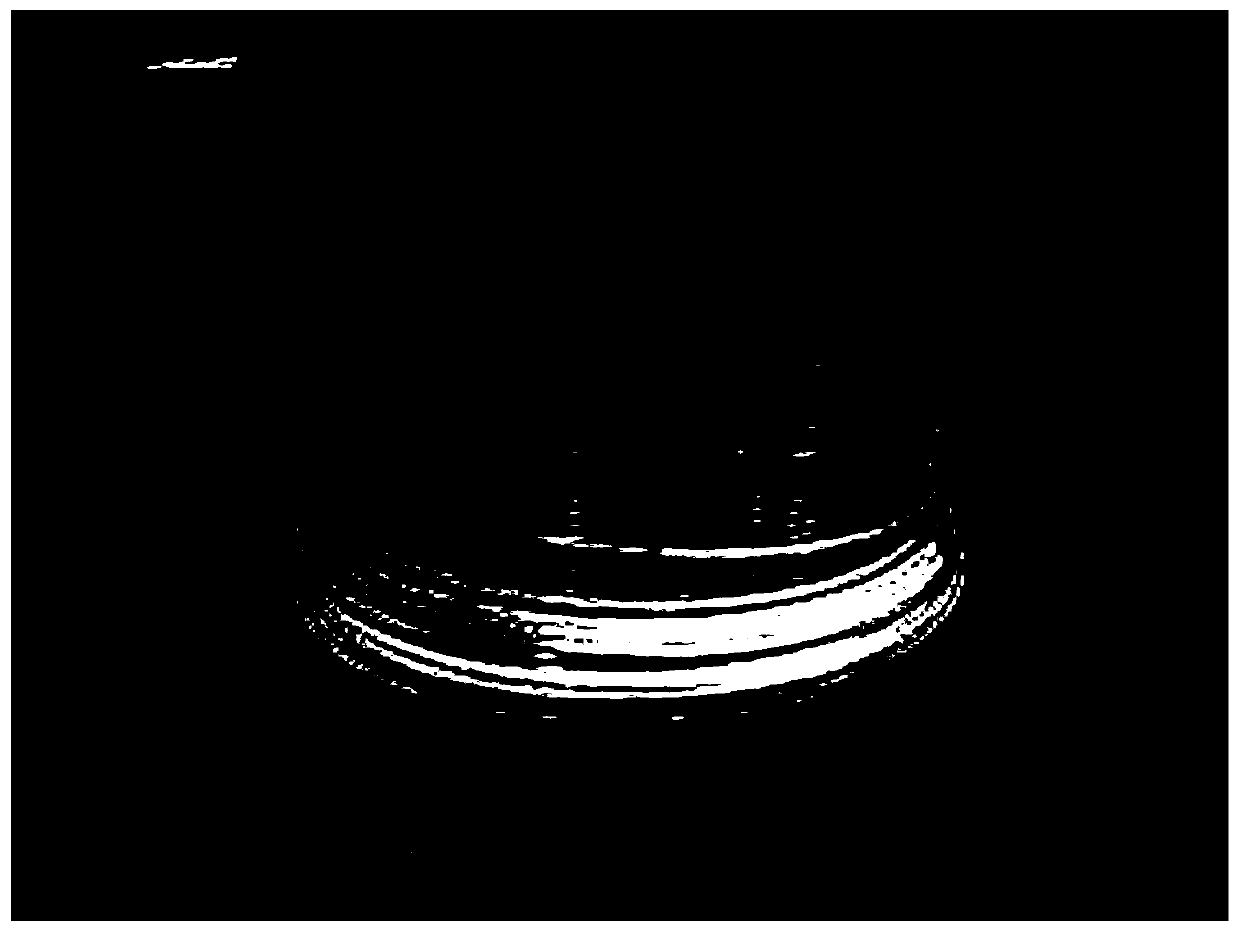

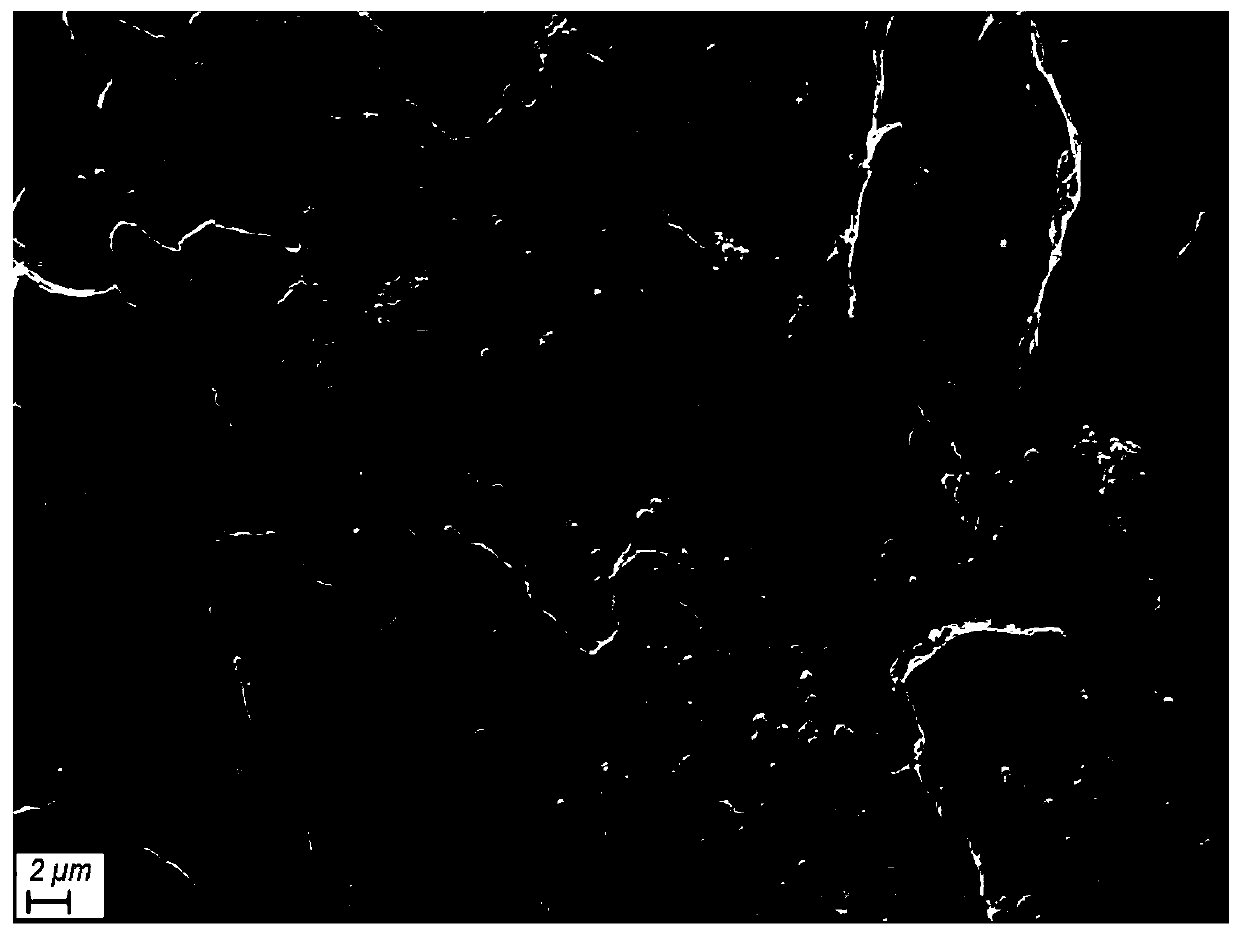

Image

Examples

preparation example Construction

[0036] The present invention will be further described below in conjunction with more specific embodiments, but it should be pointed out that the 3D printed bone repair material, preparation method and application of the present invention are not limited to this specific form or procedure. It is obvious to those skilled in the art that the following descriptions can be directly applied to other components or preparation methods of similar composite materials not specified herein even without any adjustment or modification.

[0037] like Figure 4 , 5As shown, the bone repair material constructed by 3D printing of the present invention is prepared by 3D printing using specific materials according to the shape and structure requirements of human bones, wherein the bone repair material constructed by 3D printing includes an inner core structure, The outer layer structure 3 and the antibacterial spray layer 4; wherein, the inner core structure is further divided into an inner lay...

Embodiment 1

[0052] (1) Boil the purchased beef bones in distilled water for 4 hours, remove most of the fat in the bones and remove the meat on the surface and the bone marrow inside, clean them with 30% hydrogen peroxide and 75% hydrogen peroxide respectively soaked in ethanol for 24 hours, dried in an oven at 60°C for 12 hours, the bone was broken into small pieces, then put into a ceramic crucible, and sintered in a vacuum muffle furnace at 800°C for 6 hours; The bones were placed in a high-speed pulverizer, the speed of which was maintained at 1000 rpm, and the grinding time was 4 hours to obtain self-made hydroxyapatite passing through a 800-mesh sieve;

[0053] (2) Mix the hydroxyapatite prepared above with polylactic acid, toughening agent, etc. according to the mass percentage composition of hydroxyapatite 5%, polylactic acid 80%, and toughening agent 15%, and then pass through the twin-screw The extruder realizes the process of mixing and pelletizing. Here, when the twin-screw ex...

Embodiment 2

[0058] (1) Boil the purchased pig bones in distilled water for 4 hours, remove most of the fat in the bones and remove the meat on the surface and the bone marrow inside, clean them with 30% hydrogen peroxide and 75% hydrogen peroxide respectively soaked in ethanol for 24 hours, dried in an oven at 60°C for 12 hours, then put the bones into small pieces, put them into a ceramic crucible, and sintered them in a vacuum muffle furnace at 800°C for 10 hours; The bones were placed in a high-speed pulverizer, the speed of which was maintained at 1500 rpm, and the grinding time was 3 hours to obtain self-made hydroxyapatite passing through a 800-mesh sieve;

[0059] (2) Mix the hydroxyapatite prepared above with polylactic acid, toughening agent, etc. according to the mass percentage composition of hydroxyapatite 10%, polylactic acid 70%, and toughening agent 20%, and then pass through the twin-screw The extruder realizes the process of mixing and pelletizing. Here, when the twin-scr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com