Biodegradable hydrogels for tissue repair with temperature-controlled release of nano-hydroxyapatite

A nano-hydroxyapatite, tissue repair technology, applied in the field of biomedical materials, can solve the problems of residual toxins in the body, difficult to achieve tumor cure, slow release of nHA, etc., achieve efficient and rapid apoptosis of cancer cells, promote cell adhesion and Proliferation, increase the effect of induction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

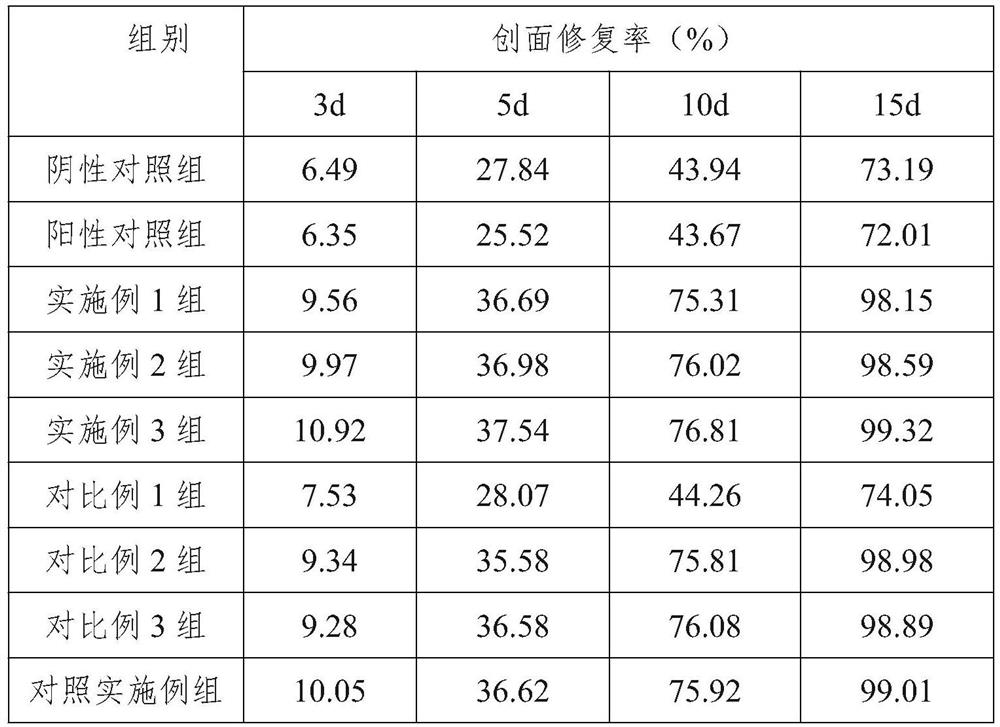

Examples

Embodiment 1

[0030] Example 1. A biodegradable hydrogel that promotes tissue repair by temperature-controlled release of nano-hydroxyapatite

[0031]The temperature-controlled release of nano-hydroxyapatite-promoting tissue repair biodegradable hydrogel includes biodegradable nanoparticles, photothermal agents, nano-hydroxyapatite particles and α-cyclodextrin, and the biodegradable The nanoparticle is a self-assembled nanoparticle of polyethylene glycol monomethyl ether-polylactic acid-hyperbranched polyglycidyl-g-dopamine; the inner core of the nanoparticle is a hydrophobic photothermal agent; the inner core of the nanoparticle is a hydrophobic photothermal agent. The function is wrapped in a biodegradable nanoparticle core; the inner layer of the nanoparticle self-assembled from polyethylene glycol monomethyl ether-polylactic acid-hyperbranched polyglycidol-g-dopamine is polylactic acid, and the outer layer is polylactic acid. Hyperbranched polyglycidyl-g-dopamine and polyethylene glycol...

Embodiment 2

[0039] Example 2. Preparation of a biodegradable hydrogel that promotes tissue repair by temperature-controlled release of nano-hydroxyapatite

[0040] The preparation method of the temperature-controlled release of nano-hydroxyapatite to promote tissue repair biodegradable hydrogel includes the following steps:

[0041] S1. Preparation of polyethylene glycol monomethyl ether-polylactic acid by solution polymerization: add 5 g of polyethylene glycol monomethyl ether to a 125 mL three-necked reaction flask, add 10 mL of anhydrous toluene, azeotropically remove water, and wait until the toluene is basically evaporated 5 g of purified L-lactide was added, and a toluene solution of 30 mg / mL stannous octoate was added, so that the stannous octoate accounted for 0.25% of the total mass of the reactants, and the three-necked reaction flask was placed in an oil bath at 70 °C, and the vacuum was removed. gas for 2 h, and then heated to 160 °C for 2 h after sealing. The reaction mixtur...

Embodiment 3

[0047] Example 3. Preparation of a biodegradable hydrogel that promotes tissue repair by temperature-controlled release of nano-hydroxyapatite

[0048] The preparation method of the temperature-controlled release of nano-hydroxyapatite to promote tissue repair biodegradable hydrogel includes the following steps:

[0049] S1. Preparation of polyethylene glycol monomethyl ether-polylactic acid by ring-opening polymerization or solution polymerization: add 5 g of polyethylene glycol monomethyl ether to a 125 mL three-neck reaction flask, add 10 mL of anhydrous toluene, azeotropically remove water, and wait until When the toluene is basically evaporated, add 5 g of purified L-lactide, add a toluene solution of 30 mg / mL stannous octoate, make stannous octoate account for 0.25% of the total mass of the reactants, and place the three-necked reaction flask in a 70°C oil bath. , degassed in vacuum for 2h, and heated to 160°C for 2h after sealing. The reaction mixture was dissolved in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com