Micro-foaming full-biodegrade polymer sheet material and preparation method thereof

A degradable polymer and all-biological technology, which is applied in the field of micro-foamed fully biodegradable polymer sheet and its preparation, can solve the problems of high equipment requirements, difficult process control, secondary pollution, etc., to reduce the apparent density, Effect of improving dispersibility, improving toughness and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

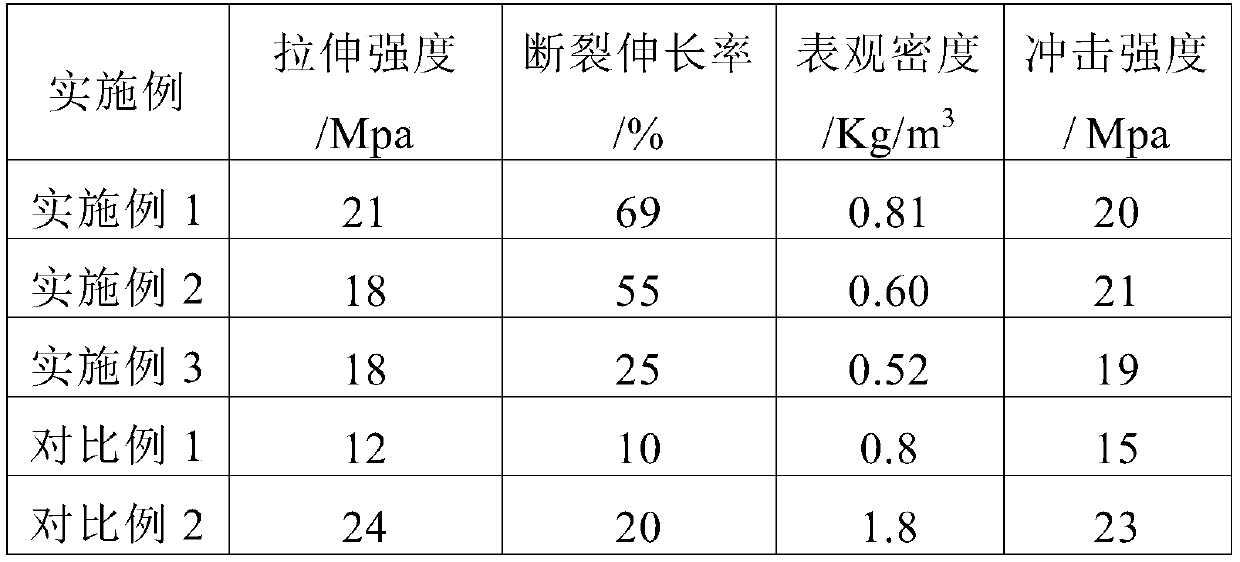

Examples

preparation example Construction

[0033] The preparation method of the micro-foamed fully biodegradable polymer sheet according to the second aspect of the present invention is used to prepare the micro-foamed fully biodegradable polymer sheet according to the first aspect of the present invention, comprising steps: (1) by Mass ratio Weigh 100 parts of polymer that can be melted and processed at low temperature, 50-100 parts of microsphere foaming agent and 5-10 parts of compatibilizer, first mix with a mixer for 1-20 minutes, and then mix with an internal mixer, Finally, a single-screw granulator or a twin-screw granulator is extruded and granulated to obtain a microsphere blowing agent masterbatch; (2) 100 parts of fully biodegradable polymers are weighed according to the mass ratio, and the microsphere blowing agent masterbatch is 3 -12 parts, 3-8 parts of compatibilizer, 10-50 parts of bio-based filler and 3-8 parts of processing aid glycerin, mixed in a high-speed mixer, the speed of the high-speed mixer i...

Embodiment 1

[0038] (1) Take by weight proportion 100 parts of ethylene-vinyl acetate copolymers whose model is E40-L of Mitsui Chemicals Company, 50 parts of acrylonitrile copolymers containing low-boiling point hydrocarbons and methyl 5 parts of glycidyl acrylic acid grafted ethylene propylene copolymer, after mixing in a mixer, knead with an internal mixer, and finally extrude and granulate with a single-screw extruder to obtain microsphere foaming agent masterbatch; The temperature of the extruder is 110°C, the temperature of each zone of the barrel of the single-screw extruder is T1=80°C, T2=85°C, T3=90°C, T4=120°C, the temperature of the head is 110°C, and the screw speed is 30r / min;

[0039] (2) Take by weighing 100 parts of polylactic acid, 3 parts of microsphere foaming agent masterbatches, 10 parts of corn starch processed by silane coupling agent and 3 parts of glycerin, and mix in a high-speed mixer. The rotating speed is 100r / min, and the mixing time is 10min to obtain the mat...

Embodiment 2

[0042] (1) Take 100 parts of ethylene-acrylic acid copolymers that the Dow Chemical Company model is 5980I by mass ratio, 100 parts of acrylonitrile copolymers containing low boiling point hydrocarbons and methacrylic acid shrinkage that the Akzo Nobel Company model is 909DU80 10 parts of glyceryl ether grafted ethylene-vinyl acetate copolymers, mixed in a mixer, kneaded with an internal mixer, and finally extruded and granulated with a twin-screw extruder to obtain microsphere foaming agent masterbatches; wherein The machine temperature is 100°C, the temperature of each zone of the twin-screw extruder barrel is T1=80°C, T2=85°C, T3=90°C, T4=110°C, the head temperature is 100°C, and the screw speed is 30r / min;

[0043] (2) Take by weight 100 parts of polyadipate / butylene terephthalate (PBAT), 12 parts of microsphere foaming agent master batches, 50 parts of wood flour processed by titanate coupling agent and 8 parts of glycerin are mixed in a high-speed mixer, the rotating spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com