Nano carbon black and nano rare earth synergistic-enhanced metal matrix micro-nano powder and preparation method thereof

A technology of nano-rare earth and nano-carbon black, applied in the field of metal-based micro-nano powder for laser remanufacturing and its preparation, nano-carbon black and nano-rare earth synergistically enhanced metal-based micro-nano powder and its preparation, which can solve the problem of laser absorption rate Low heat input, high heat input, etc., to achieve good application prospects, narrow heat-affected zone, and improved wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

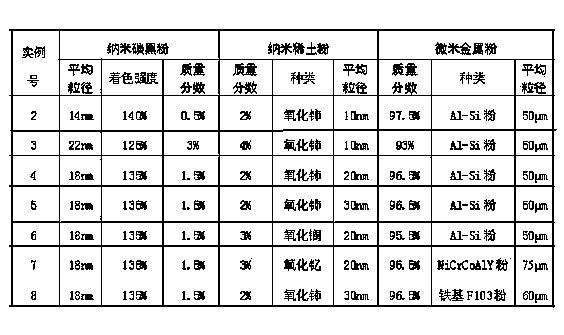

[0040] Materials used in this embodiment: the average particle diameter of nano-carbon black powder is 18nm, the tinting strength is 135%, and the mass fraction is 2%; the nano-rare earth powder is cerium oxide, and its average particle diameter is 20nm, and the mass fraction is 3%; The powder is Al-Si alloy powder, the average particle size is 50 μm, and the mass fraction is 95%; adopt the above-mentioned steps to prepare the metal-based micro-nano powder synergistically reinforced by nano-carbon black and nano-rare earth, and its ball milling composite parameter is that the ball milling speed is 200 rpm / Minutes, the ratio of ball to material is 8:1, and the ball milling time is 1 hour. Observed by scanning electron microscope, the prepared micro-nano powder maintains the spherical characteristics of micro-powder ( figure 1 ), its surface is coated with a large number of nano-carbon black powder and nano-rare earth powder with high dispersion characteristics ( figure 2 ), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com