Glass composition for front silver paste of crystalline silicon solar perc cell and preparation method thereof

A glass composition and solar energy technology, which is applied in the field of glass for silver paste on the front side of crystalline silicon solar cells, can solve the problems of shortened component life, low electrode adhesion, and low production capacity, and achieve good applicability and solve functional requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] Another object of the present invention is to provide a method for preparing the glass composition for front silver paste of silicon solar PERC cells, comprising: uniformly mixing according to the predetermined ratio to obtain mixed raw materials, putting the mixed raw materials into a platinum crucible, and then Put the platinum crucible into a high-temperature box furnace to heat up, and keep it warm at a temperature of 1100-1300°C for 0.5-1 hour, so that the melt completely becomes a homogeneous liquid and does not contain any residual raw material decomposition products; The homogeneous liquid is poured into deionized water for water quenching, and the glass particles are taken out after cooling, and put into a blast oven for drying; the dried glass particles, grinding balls, and deionized water are put into a ball mill jar And seal it, put it into a ball mill for ball milling, and after ball milling for 2-5 hours, sieve and filter out the balls to obtain glass slurr...

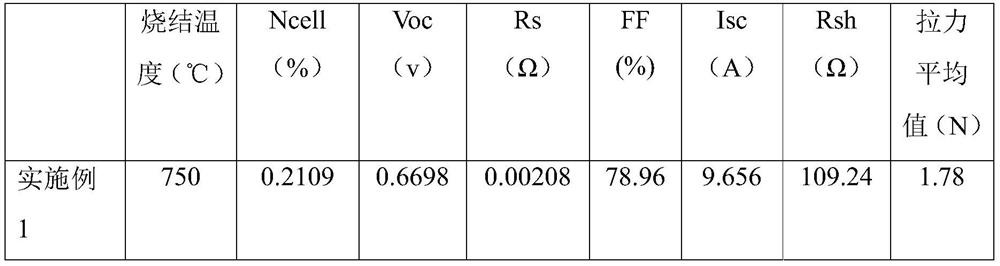

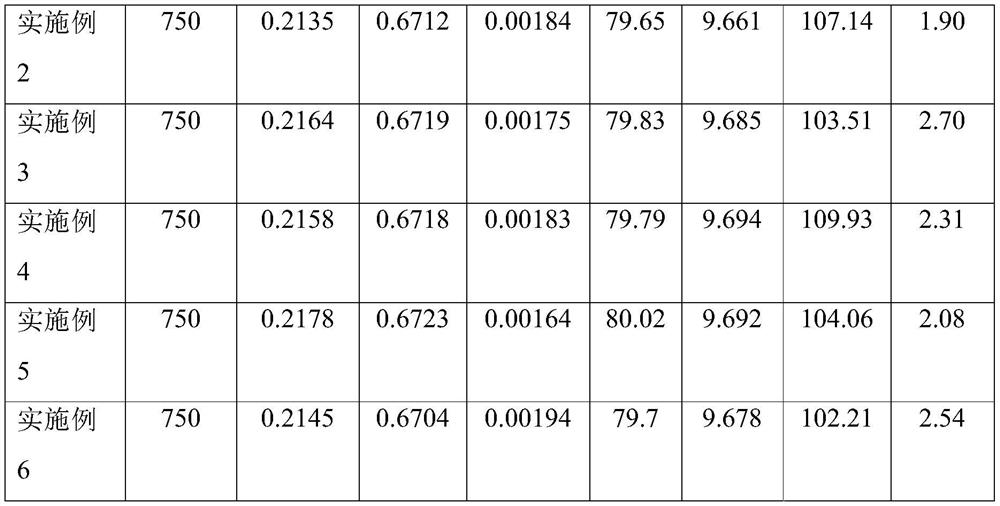

Embodiment 1-6

[0069] For the silver paste glass composition on the front side of crystalline silicon solar PERC cells, the formula of lead-free glass (a) is according to No. 1-6 formula in Table 1, and the lead-containing glass (b) is according to No. 7-12 formula in Table 2, after After components adjustment, melting, water quenching, drying, ball milling, sieving and other processes, a glass composition with low softening temperature, high adhesion and low RS after sintering of silver paste on the front side of crystalline silicon solar PERC cells is obtained. The glass composition in the formula also includes 0.01-5wt% of additives; the additives are selected from the group consisting of: (1) metals, wherein the metals are selected from strontium, barium, titanium, zirconium, vanadium, niobium, Chromium, molybdenum, tungsten, manganese, iron, ruthenium, rhodium, cobalt, nickel, copper, tin, cerium and gadolinium; (ii) metal oxides of one or more metals selected from Strontium, barium, ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com