Surface modified titanium implant and functional treatment method thereof

A technology of surface functionalization and treatment method, which is applied in the direction of surface reaction electrolytic coating, pharmaceutical formulation, drug delivery, etc., can solve the problem of poor hydrophilicity, low content of anatase and rutile titanium oxide, titanium oxide layer and hydroxyapatite Problems such as low bonding strength of stone layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] S1. Degreasing: The titanium implant was ultrasonically cleaned at 60°C for 15 minutes with an oil-removing cleaning agent containing 1 wt% neutral surfactant (specifically, PWC-401 cleaning agent, the same below), to obtain a degreasing titanium implant. body.

[0037] S2. Pickling: pickling the degreasing titanium implant with a hydrofluoric acid aqueous solution with a concentration of 10 wt% at room temperature to obtain an acid-washed titanium implant.

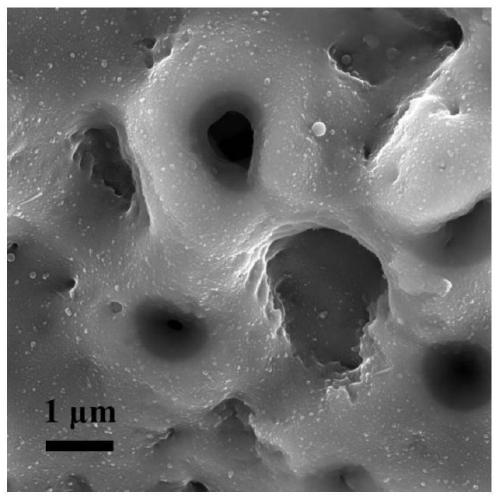

[0038] S3, micro-arc oxidation treatment: adding sodium phosphate, potassium carbonate and ammonium molybdate into ethanol and stirring and dissolving to obtain a solution with a sodium salt concentration of 2g / L, a potassium salt solution concentration of 10g / L and an ammonium salt solution concentration of 5g / L mixture. The acid-washed titanium implant is placed in the mixed solution for micro-arc oxidation treatment at 20°C, the oxidation voltage is a gradient step voltage, the step step is 5 stages, the step o...

Embodiment 2

[0045] S1. Degreasing: The titanium implant was ultrasonically degreased and cleaned at 60° C. for 20 minutes with a degreasing agent containing 5 wt % neutral surfactant to obtain a degreased titanium implant.

[0046] S2. Pickling: pickling the degreasing titanium implant with a hydrofluoric acid aqueous solution with a concentration of 10 wt% at room temperature to obtain an acid-washed titanium implant.

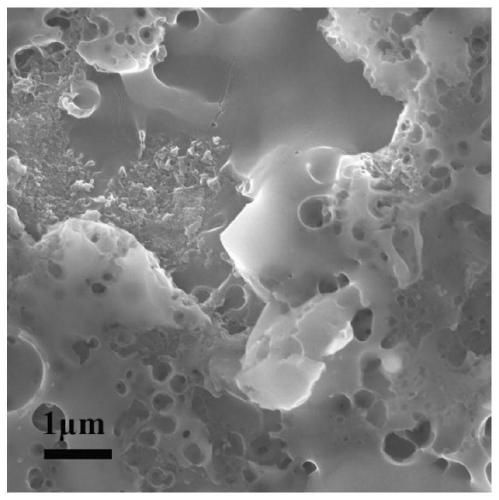

[0047] S3, micro-arc oxidation treatment: adding sodium citrate, potassium sulfate and ammonium bicarbonate into ethanol and stirring and dissolving to obtain a sodium salt solution concentration of 2 g / L, a potassium salt solution concentration of 10 g / L and an ammonium salt solution concentration of 5 g / L mixed solution. The acid-washed titanium implant is placed in the mixed solution for micro-arc oxidation treatment at 30°C, the oxidation voltage is a gradient step voltage, the step step is 2 stages, the step output voltage is 500V, and the duty cycle is 15%, and the...

Embodiment 3

[0054] S1. Degreasing: The titanium implant was ultrasonically degreased and cleaned at 60° C. for 18 minutes with a degreasing agent containing 3 wt % neutral surfactant to obtain a degreased titanium implant.

[0055]S2. Pickling: pickling the degreasing titanium implant with a hydrofluoric acid aqueous solution with a concentration of 10 wt% at room temperature to obtain an acid-washed titanium implant.

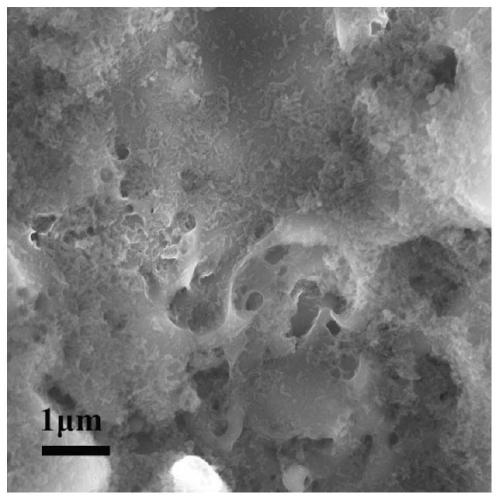

[0056] S3, micro-arc oxidation treatment: add sodium edetate, potassium chloride and ammonium citrate into ethanol and stir to dissolve, to obtain a sodium salt solution concentration of 2g / L, a potassium salt solution concentration of 10g / L and an ammonium salt solution concentration It is a mixed solution of 5g / L. The acid-washed titanium implant is placed in the mixed solution for micro-arc oxidation treatment at 45°C, the oxidation voltage is a gradient step voltage, the step step is 3 stages, the step output voltage is 750V, and the duty cycle is 30%, and the oxidati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com