High-buffering and shock-proof environmental-protection ceramic product and preparation method thereof

A technology for buffering shock-proof and ceramic products, applied in the field of ceramics, can solve the problems of non-vibration-proof restriction, poor deformation ability, and inability to shock-proof, etc., to achieve good thermal insulation, reduce production costs, and improve the effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

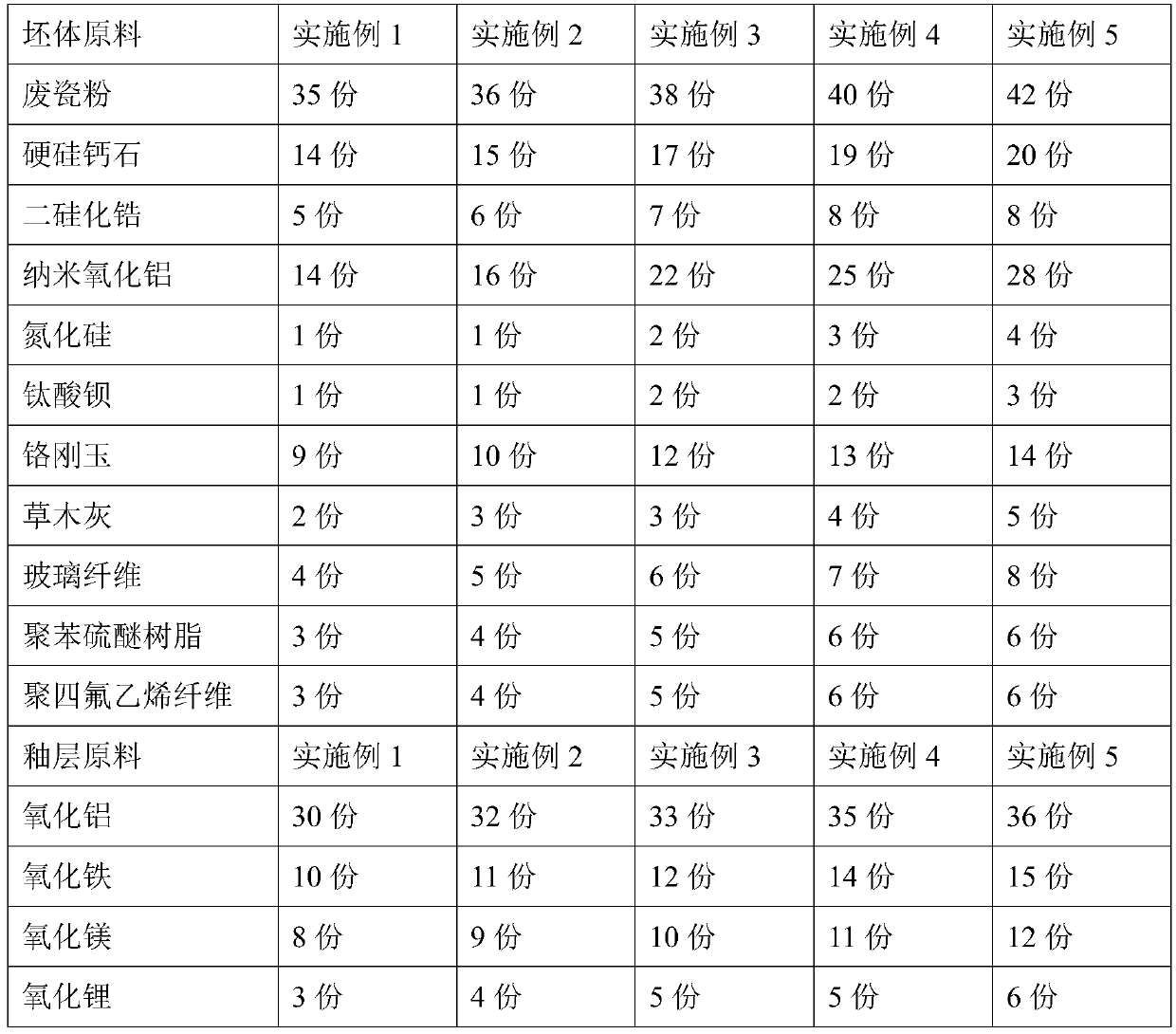

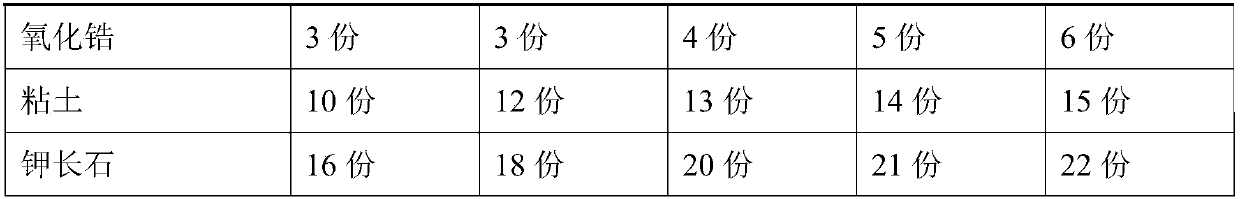

Embodiment 1

[0027] This embodiment provides a high-buffer, shock-proof and environmentally friendly ceramic product, which includes a tire material and a glaze. The tire material includes the following raw materials by weight: 35 parts of waste porcelain powder, 14 parts of xonotlite, 5 parts of zirconium disilicide, nano 14 parts of alumina, 1 part of silicon nitride, 1 part of barium titanate, 9 parts of chromium corundum, 2 parts of plant ash, 4 parts of glass fiber, 3 parts of polyphenylene sulfide resin, 3 parts of polytetrafluoroethylene fiber;

[0028] The glaze includes the following raw materials in parts by weight: 30 parts by weight of alumina, 10 parts by iron oxide, 8 parts by magnesium oxide, 3 parts by lithium oxide, 3 parts by zirconium oxide, 10 parts by clay, and 16 parts by potash feldspar.

[0029] This embodiment also provides a method for preparing a high-buffer, shock-proof and environmentally friendly ceramic product, which includes the following steps:

[0030] Step 1. W...

Embodiment 2

[0037] This embodiment provides a high-buffer, shock-proof and environmentally friendly ceramic product, which includes a tire material and a glaze. The tire material includes the following raw materials by weight: 36 parts of waste porcelain powder, 15 parts of xonotlite, 6 parts of zirconium disilicide, nano 16 parts of alumina, 1 part of silicon nitride, 1 part of barium titanate, 10 parts of chromium corundum, 3 parts of plant ash, 5 parts of glass fiber, 4 parts of polyphenylene sulfide resin, 4 parts of polytetrafluoroethylene fiber;

[0038] The glaze includes the following raw materials in parts by weight: 32 parts by weight of alumina, 11 parts by iron oxide, 9 parts by magnesium oxide, 4 parts by lithium oxide, 3 parts by zirconium oxide, 12 parts by clay, and 18 parts by potash feldspar.

[0039] This embodiment also provides a method for preparing a high-buffer, shock-proof and environmentally friendly ceramic product, which includes the following steps:

[0040] Step 1. ...

Embodiment 3

[0047] This embodiment provides a high-buffer, shock-proof and environmentally friendly ceramic product, which includes a tire material and a glaze. The tire material includes the following parts by weight of raw materials: 38 parts of waste porcelain powder, 17 parts of xonotlite, 7 parts of zirconium disilicide, nano 22 parts of aluminum oxide, 2 parts of silicon nitride, 2 parts of barium titanate, 12 parts of chromium corundum, 3 parts of plant ash, 6 parts of glass fiber, 5 parts of polyphenylene sulfide resin, 5 parts of polytetrafluoroethylene fiber;

[0048] The glaze includes the following raw materials in parts by weight: 33 parts by weight of alumina, 12 parts by iron oxide, 10 parts by magnesium oxide, 5 parts by lithium oxide, 4 parts by zirconium oxide, 13 parts by clay, and 20 parts by potash feldspar.

[0049] This embodiment also provides a method for preparing a high-buffer, shock-proof and environmentally friendly ceramic product, which includes the following step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com