Photoelectric detector with two-dimensional transition metal sulfide film nanoscroll

A photodetector and transition metal technology, applied in nanotechnology for sensing, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as poor stability, poor photosensitivity, and poor light absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Second object of the present invention is to provide the preparation method of above-mentioned photodetector, comprise the steps:

[0025] Deposit tetrathiomolybdenum / ammonium tungstate on silicon substrate;

[0026] Decompose tetrathiomolybdenum / ammonium tungstate into single-layer molybdenum disulfide / tungsten film by thermal decomposition method;

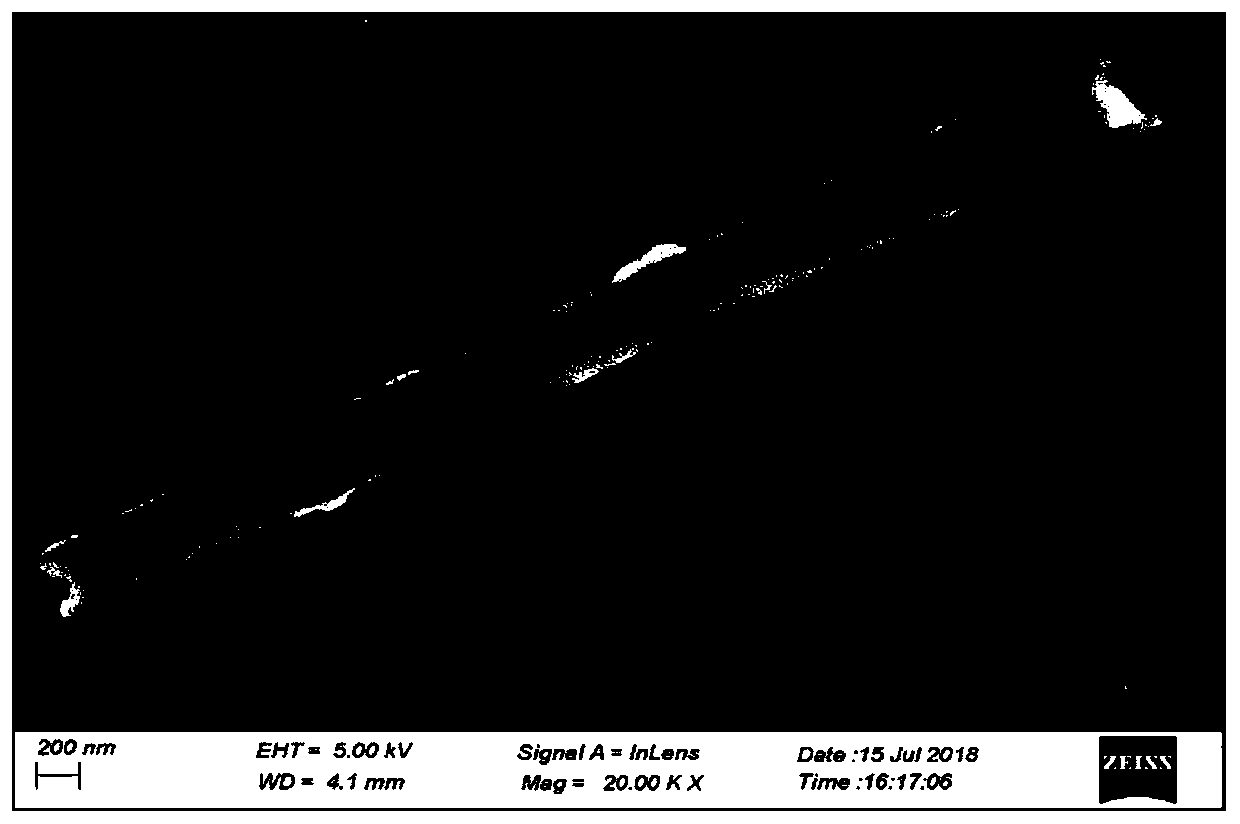

[0027] Add the ethanol solution dropwise on one side of the surface of the silicon substrate with a molybdenum disulfide / tungsten monolayer film, and the ethanol solution volatilizes to generate a temperature gradient and a surface tension gradient on the surface of the silicon substrate. Under the action of the two, disulfide The molybdenum / tungsten monolayer film automatically curls from one side to form a nanocoil helical structure;

[0028] The source and drain electrodes were etched by UV lithography on both sides of the nanoscroll helical structure to obtain a photodetector.

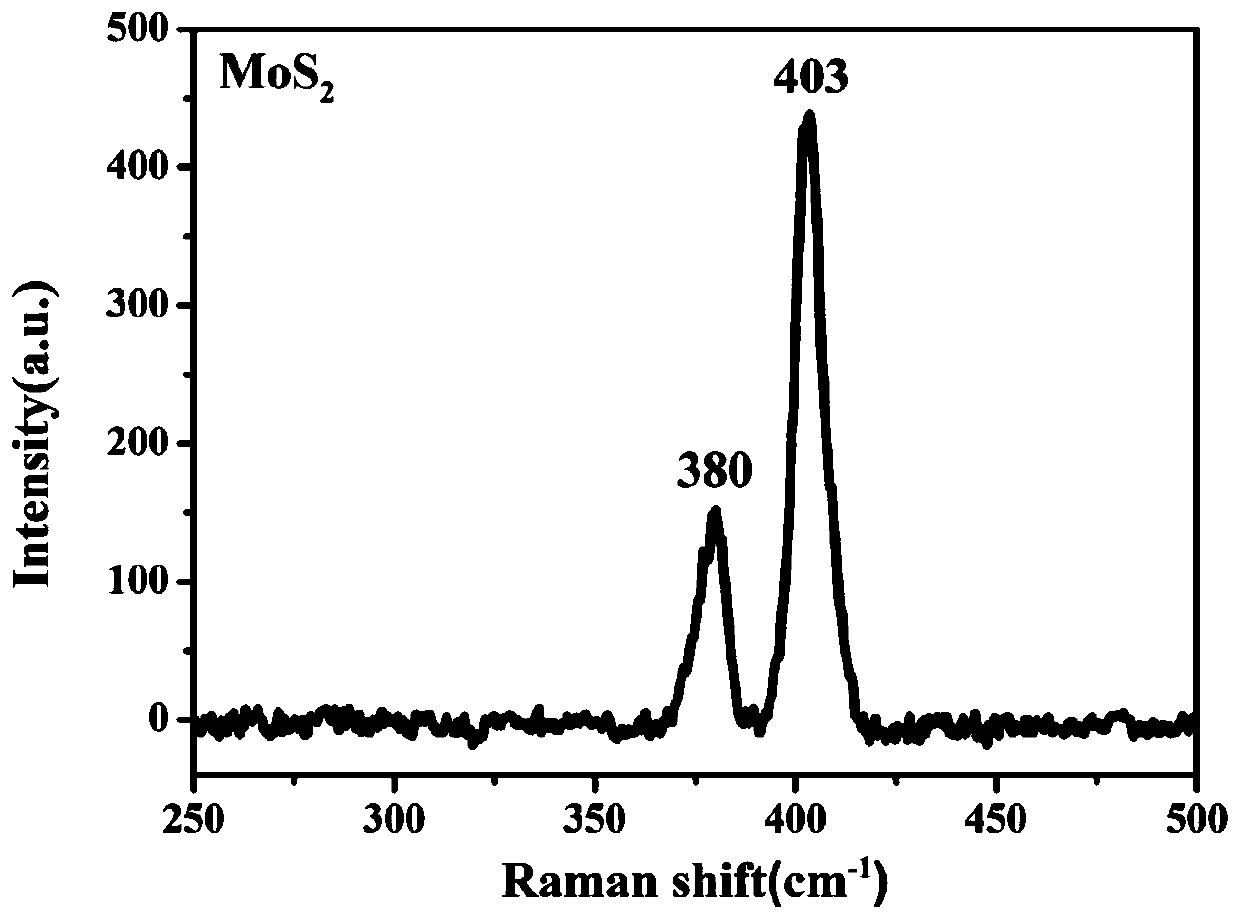

[0029] The grown disulfide films are m...

Embodiment 1

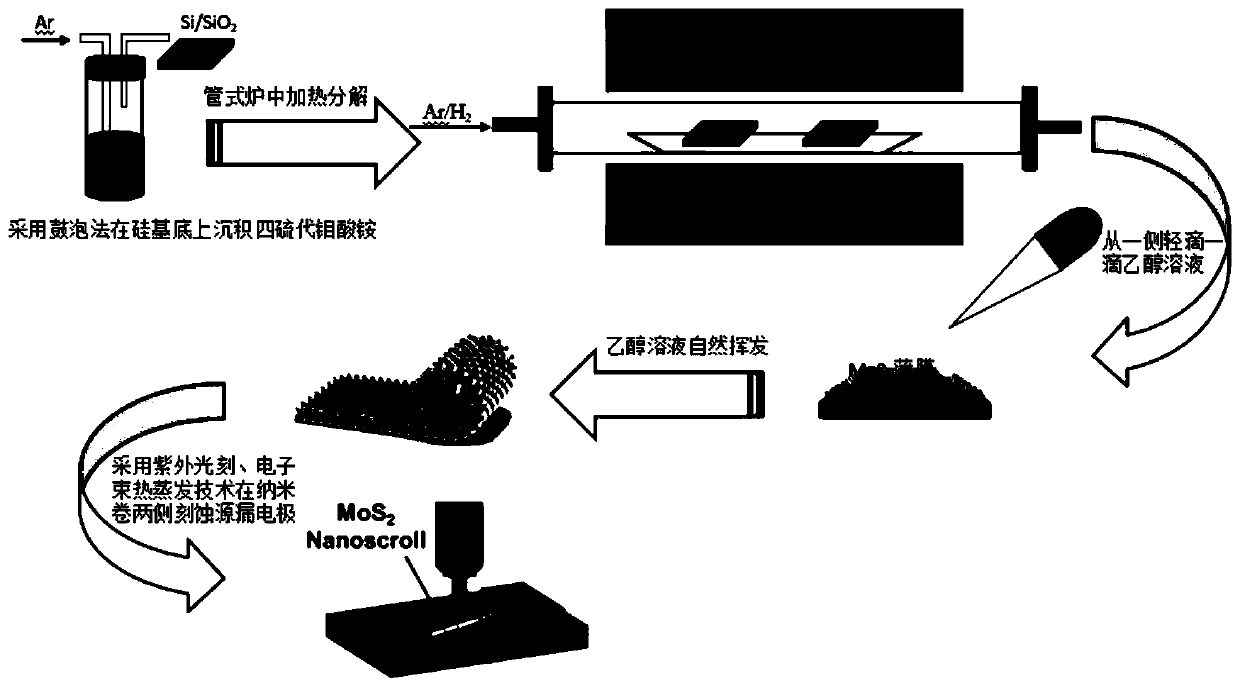

[0048] Nanoscroll-helical photodetector materials of two-dimensional transition metal dichalcogenide thin films, such as figure 2 The shown preparation roadmap includes the following preparation steps:

[0049] Deposit ammonium tetrathiomolybdate on the silicon / silicon dioxide substrate by bubbling method, and control the ambient temperature at 22-26°C:

[0050] 1) Put 0.2g of ammonium tetrathiomolybdate powder into a special scrubber bottle, add 1mL of dimethylformamide, and ultrasonicate the ammonium tetrathiomolybdate solution for 100 minutes to obtain ammonium tetrathiomolybdate solution.

[0051] 2) silicon / silicon dioxide substrate (the area of the deposition surface of silicon substrate is 1cm 2 ) were successively washed with toluene, acetone, absolute ethanol, and deionized water for 30 minutes each.

[0052] 3) Place the clean silicon / silica substrate into the short end of the scrubber bottle.

[0053] 4) Connect the long mouth end of the gas collecting bottle...

Embodiment 2

[0069] Nanoscroll-helical photodetector materials of two-dimensional transition metal dichalcogenide thin films, such as figure 2 The shown preparation roadmap includes the following preparation steps:

[0070] Deposition of ammonium tetrathiomolybdate on silicon / silica substrates by bubbling:

[0071] 1) Take 0.2g of ammonium tetrathiotungstate powder and put it into a special scrubber bottle, add 1mL of dimethylformamide, and ultrasonicate the ammonium tetrathiotungstate solution for 100 minutes to obtain ammonium tetrathiomolybdate solution.

[0072] 2) silicon / silicon dioxide substrate (the area of the deposition surface of silicon substrate is 50cm 2 ) were successively washed with toluene, acetone, absolute ethanol, and deionized water for 30 minutes each.

[0073] 3) Place the clean silicon / silica substrate into the short end of the scrubber bottle.

[0074] 4) Connect the long mouth end of the gas collecting bottle to argon gas, and the gas flow rate is 110 sccm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com