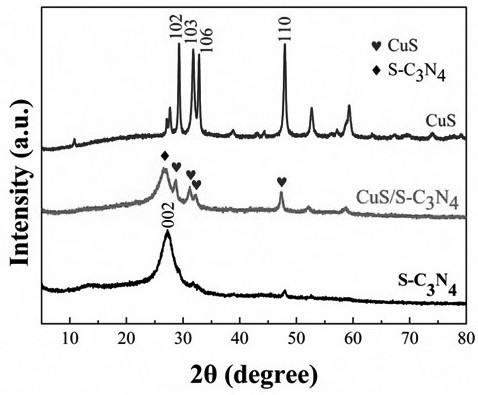

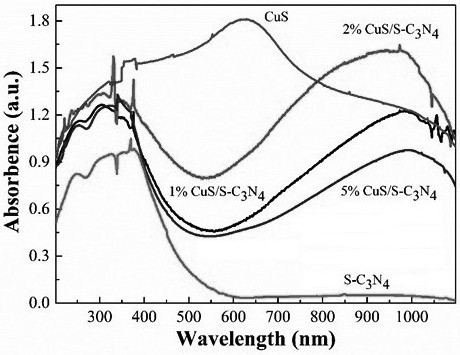

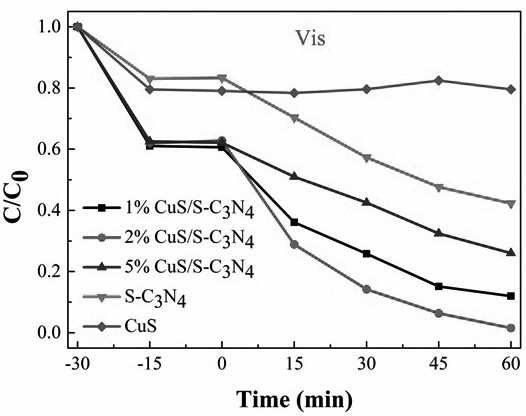

Preparation method of near-infrared light response CuS/S-C3N4 heterojunction nanocomposite

A technology of S-C3N4 and nano-composite materials, which is applied in the field of environmental pollution control, can solve the problems that legacy pollution is difficult to be solved reasonably, and achieve the effects of improving utilization efficiency, improving absorption, and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Near infrared light response CUS / S-C 3 N 4 Preparation of heterogeneous nano-composite materials, its preparation steps are:

[0023] (1) Weighing 10 g of urea in the secondary distilled water of 15 mL at 50 ° C, and then dissolved, then 100 mg of thioacetamide continued to completely dissolve.

[0024] (2) The mixed solution obtained by step (1) is transferred to the semi-sealing crucible and then sent to the rapid heating furnace, and the set procedure is 10 ° C from room temperature to 300 ° C holding 0.5 h, and then 10 ° C / min twice The temperature rise to 400 ° C insulation 1 h, then the yellow product obtained after natural cooling is SC 3 N 4 .

[0025] (3) 1.28 g s-c 3 N 4 The addition of 80 ml of secondary distilled water was added and dispersed evenly. It is repeated that 50 mg of pentaqueraphic sulfate and 100 mg thioacetamide were further added to the above solution under stirring conditions.

[0026] (4) After thoroughly stirring, transferred to the reactor...

Embodiment 2

[0028] Near infrared light response CUS / S-C 3 N 4 Preparation of heterogeneous nano-composite materials, its preparation steps are:

[0029] (1) Weigh 15 g of urea to stir at 50 ° C in a secondary distilled water at 20 mL, and then dissolved, then 150 mg of thioacetamide continued to stir until completely dissolved.

[0030] (2) Transferring the mixed solution obtained by step (1) to the semi-sealing crucible and then fed into the rapid heating furnace, and the set procedure temperature temperature increases from room temperature to 400 ° C to heat insulation 1 h, and then 15 ° C / min twice The temperature rise to 500 ° C insulation 2 h, and then the yellow product obtained after natural cooling is SC. 3 N 4 .

[0031] (3) 2.28 g s-c 3 N 4 The addition of 80 ml of secondary distilled water was added and dispersed evenly. Further, 75 mg of pentaqueraphic sulfate and 115 mg thioacetamide were added to the above solution under stirring conditions.

[0032] (4) After thoroughly sti...

Embodiment 3

[0034] Near infrared light response CUS / S-C 3 N 4 Preparation of heterogeneous nano-composite materials, its preparation steps are:

[0035] (1) Weigh 20 g of urea to stir in the secondary distilled water of 30 mL at 50 ° C, and then dissolved, then 180 mg of thiocanoacetamide continued to completely dissolve.

[0036] (2) Transferring the mixed solution obtained by step (1) to the semi-sealing crucible and then fed into the rapid heating furnace, the set procedure temperature temperature above the room temperature to 500 ° C for 2 h, then 20 ° C / min twice The temperature increased to 600 ° C for 3 h, and then the yellow product obtained after natural cooling is SC. 3 N 4 .

[0037] (3) 3.28 g s-c 3 N 4The addition of 80 ml of secondary distilled water was added and dispersed evenly. It is repeated that 100 mg of five hydrotropic sulfate and 150 mg thioacetamides were added to the above solution under stirring conditions.

[0038] (4) Through agitation, transferred to the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com