Cr-C-N-based metal ceramic and preparation method thereof

A metal-based, cr-c-n technology, applied in the field of cermet materials, can solve the problems of difficult process, poor bending strength and hardness, etc., and achieve the effect of easy control of conditions, simple process and favorable industrialization promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

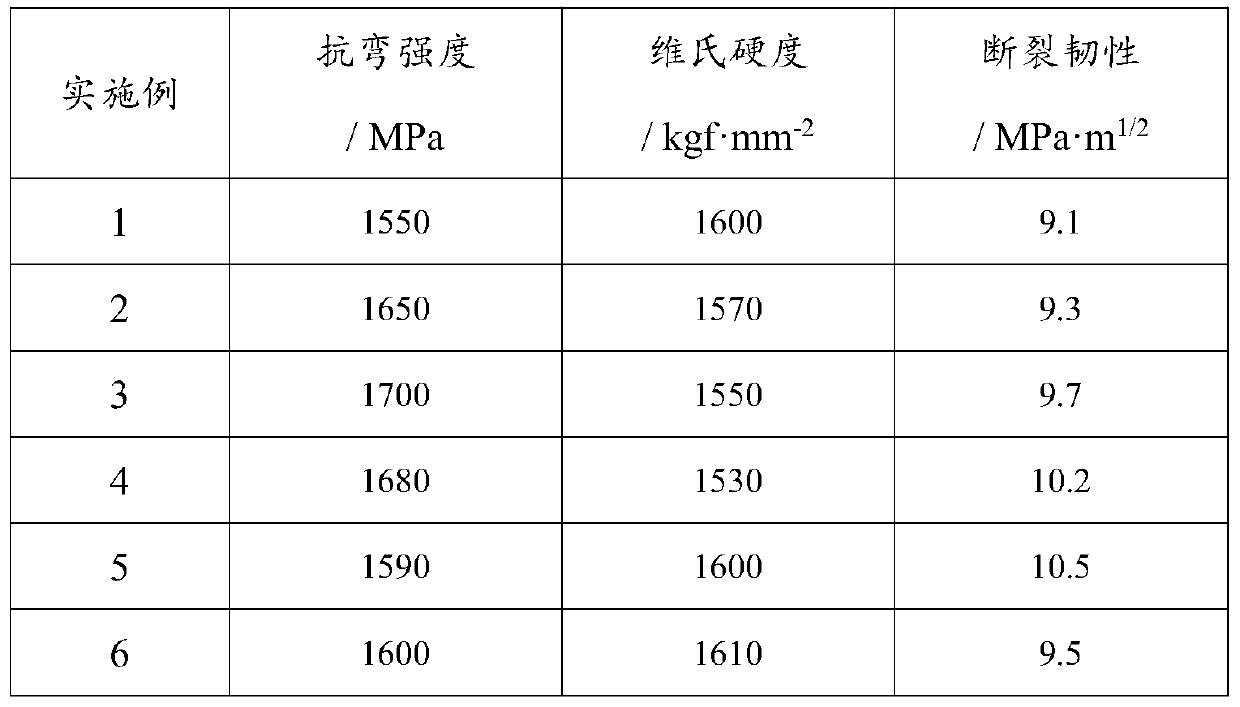

Examples

preparation example Construction

[0052] The present invention provides a method for preparing the Cr-C-N-based cermet described in the above technical solution, comprising the following steps:

[0053] (1) The Cr-C-N hard phase powder, metal powder and carbide powder are mixed by ball milling and then dried to obtain a mixture;

[0054] (II) After mixing the mixture with a molding agent, granulating and pressing are performed sequentially to obtain a molding material;

[0055] (III) Sintering the molding material to obtain the Cr-C-N-based cermet.

[0056] In the invention, the Cr-C-N hard phase powder, metal powder and carbide powder are mixed by ball milling and then dried to obtain a mixture. In the present invention, the ball-to-material ratio of ball milling in the step (I) is preferably 4:1 to 8:1, more preferably 6:1; the time for ball milling is preferably 40 to 80 hours, more preferably 60h; the mixing medium of the ball mill is one or more of absolute ethanol, absolute methanol and acetone. The p...

Embodiment 1

[0062] (1) Powder making: Weigh 80 grams of chromium oxide and 20 grams of carbon black and put them into a ball mill jar, and ball mill and mix them for 20 hours. The mixing medium is absolute ethanol. Take out the mixture and put it in an oven for drying. In the furnace, the temperature was raised to 1200°C for 1 hour under flowing nitrogen, and the nitrogen flow rate was 2L / min. After cooling with the furnace, a Cr-C-N single-phase powder with a C content of 0.1% and a N content of 11% was obtained, which was taken out, crushed, Sieve and package.

[0063](2) Ball mill mixing: Weigh 60 grams of Cr-C-N single-phase powder prepared in step (1), 20 grams of Cr-Ni alloy powder, and 20 grams of TiC powder, and put them into a ball mill tank with a ball-to-material ratio of 4: 1. The ball milling medium is absolute ethanol, and the ball milling is mixed for 60 hours, and the mixture is taken out and put into an oven for drying.

[0064] (3) Granulating and pressing: In the mixtu...

Embodiment 2

[0067] (1) Powder making: Weigh 86 grams of ammonium chromate and 14 g of glucose, dissolve them in deionized water, stir until they are evenly mixed, concentrate and dry at 85°C for 2 hours to prepare mixed precursor powder, and then store them at 400°C under the protection of argon Calcined for 4 hours, transferred to a heat treatment furnace, heated to 1300°C under flowing nitrogen for heat treatment for 0.5 hours, and the nitrogen flow rate was 3L / min. After cooling with the furnace, Cr-C-N with a C content of 2.1% and an N content of 9.2% was obtained. Single-phase powder, taking out, crushing, sieving, packaging.

[0068] (2) Ball mill mixing: Weigh 60 grams of Cr-C-N single-phase powder prepared in step (1), 10 grams of Ni powder, and 30 grams of WC powder, put them into a ball mill tank, the ratio of ball to material is 8:1, and ball mill The medium is acetone, ball milled and mixed for 40 hours, and the mixed material is taken out and put into an oven for drying.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com