Marine high-strain welded steel pipe based on double-phase structure and preparing method thereof

A dual-phase structure, welded steel pipe technology, applied in the field of welded steel pipe manufacturing, can solve the problems of large influence on material properties, poor quality stability, etc., achieve small strain aging effect, small deviation of outer diameter and out-of-roundness, and save marine development costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

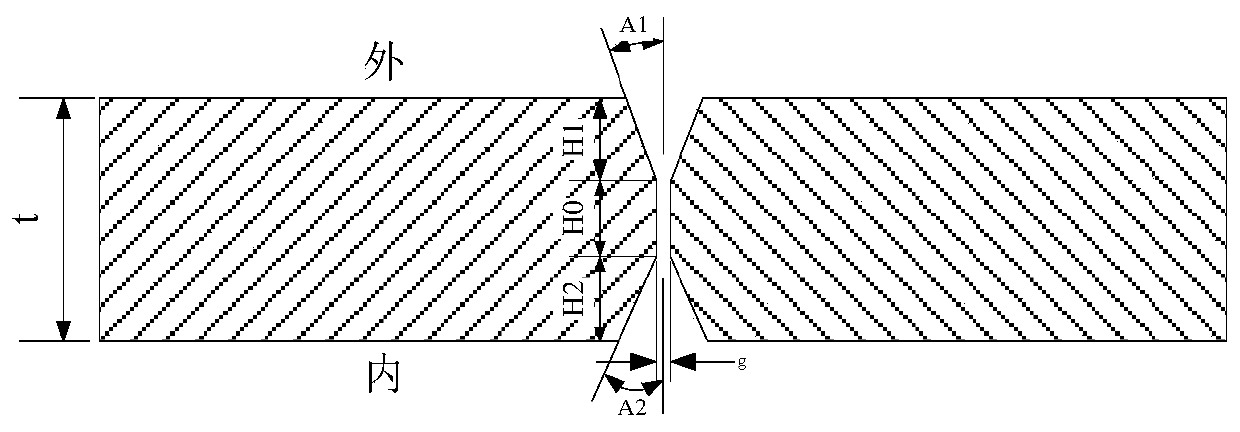

Image

Examples

Embodiment

[0071] Take Φ559×31.8mm L485MO UOE straight seam submerged arc welded steel pipe as an example.

[0072] 1. Determination of steel plate structure type: select a wide and thick steel plate with polygonal ferrite (PF) + bainite (B) dual-phase structure, and the phase ratio of PF and B is 1.50-1.63.

[0073] 2. Chemical composition of the steel plate: The mass percentage of the chemical composition of the wide and thick steel plate is 0.046% carbon, 0.18% silicon, 1.74% manganese, 0.0012% sulfur, 0.0062% phosphorus, 0.13% chromium, 0.22% nickel, 0.12% molybdenum, copper 0.18%, niobium+vanadium+titanium≤0.12%, boron 0.0002%, aluminum 0.0028%, nitrogen 0.0038%, the rest is iron and residual impurity elements, cold crack sensitivity index Pcm≤0.17%.

[0074] 3. Steel grade and specification: The steel grade of the wide and thick steel plate used is L485MO, and the thickness is 31.8mm. Considering the amount of deformation during the forming process and the processing allowance of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com