Titanium dioxide nanocomposite material and preparation method and application thereof

A nanocomposite material, titanium dioxide technology, applied in the direction of nanotechnology, nanotechnology, microsphere preparation, etc., can solve the problems of not being able to effectively improve the photochemical activity, not be able to effectively improve the dispersion, not be able to form a dense coating layer, etc., to reduce the photochemical Effects of active, natural color and natural skin whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

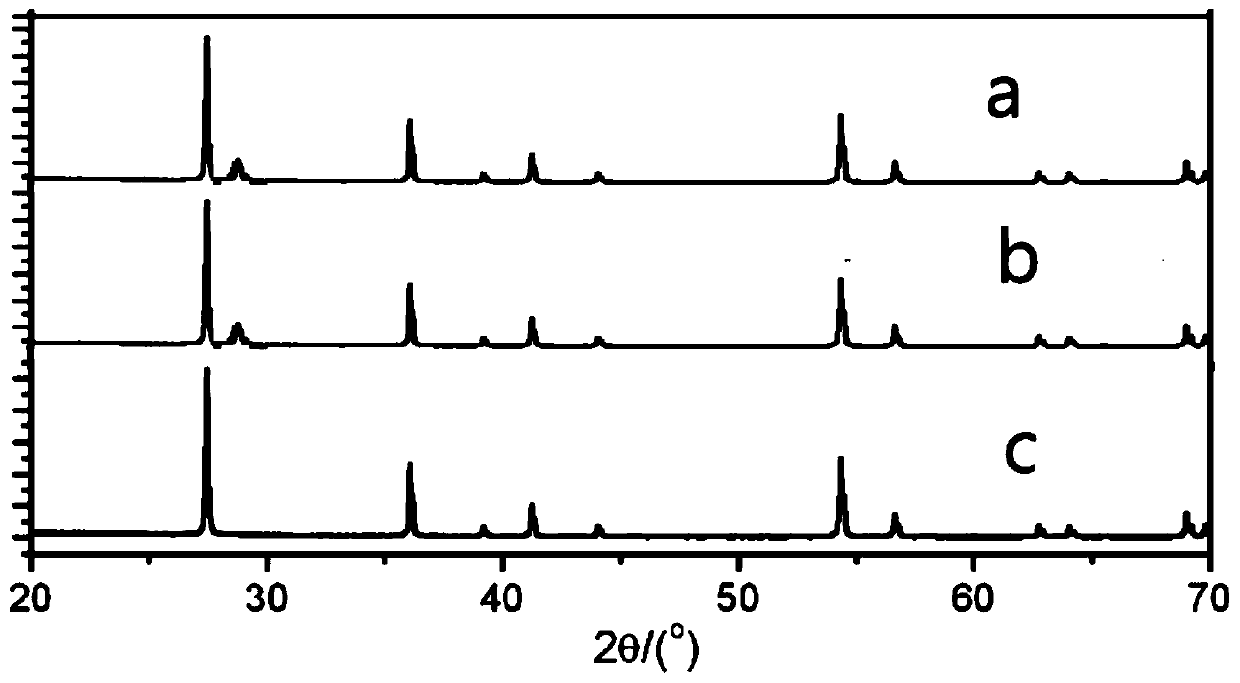

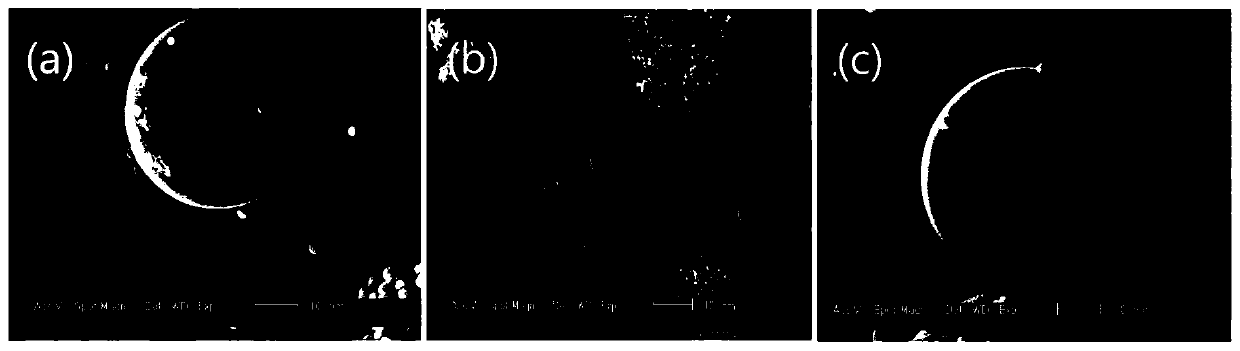

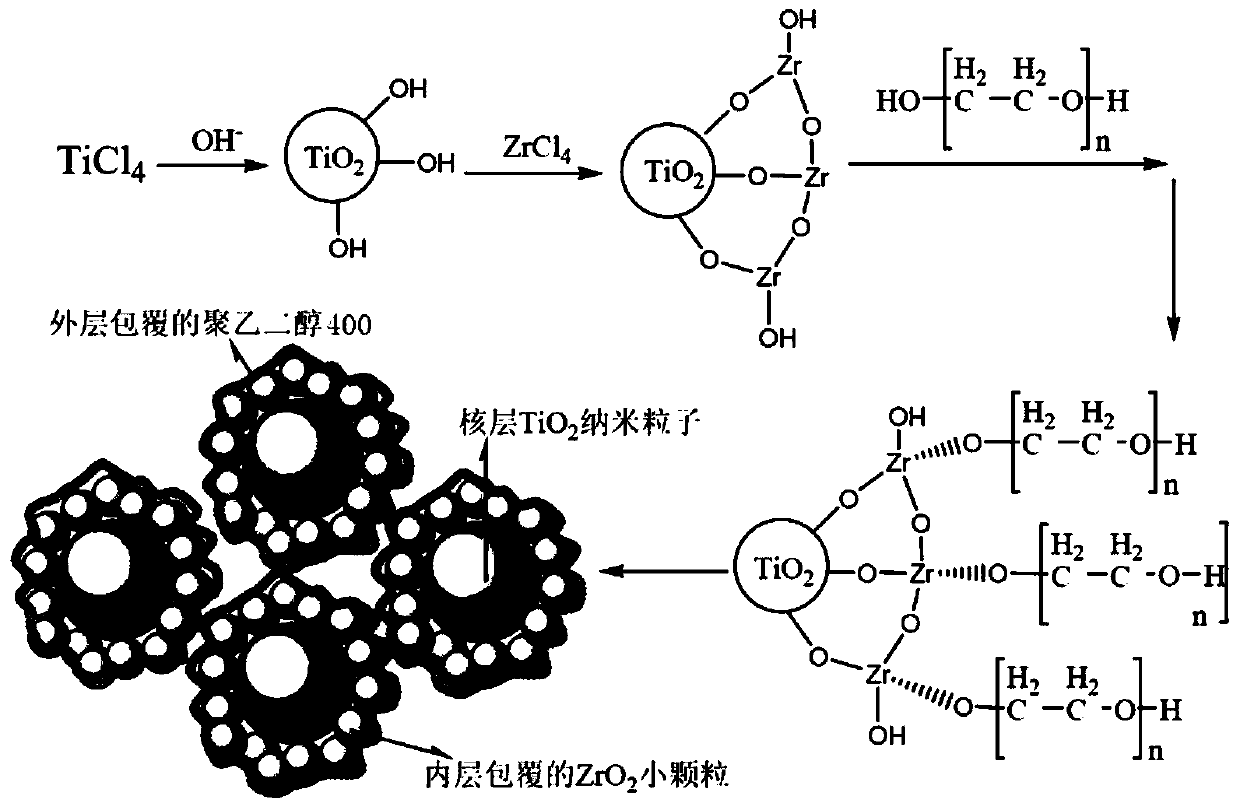

[0037] A titanium dioxide nanocomposite material comprising TiO 2 Nanoparticles, TiO 2 Nanoparticles coated with ZrO 2 Inorganic layer forming TiO 2 @ZrO 2 Core-shell nanoparticles, TiO 2 @ZrO 2 The surface of the core-shell nanoparticle is coated with a surfactant organic film layer, that is, TiO 2 @ZrO 2 The surface of the core-shell nanoparticle is modified with polyethylene glycol 400.

[0038] In the titanium dioxide nanocomposite material of this embodiment, TiO 2 The mass percentage of nanoparticles is 95.3%, ZrO 2 The mass percentage of the inorganic film layer is 4.1%, and the mass percentage of polyethylene glycol 400 is 0.6%.

[0039] In the titanium dioxide nanocomposite material of this embodiment, TiO 2 The crystal form of nanoparticles is rutile.

[0040] The titanium dioxide nanocomposite material of this embodiment has a whiteness of 95%, a primary particle diameter of 25nm, and a specific surface area of 77.9m 2 / g.

[0041] A preparation metho...

Embodiment 2

[0054] An application of a titanium dioxide nanocomposite material in cosmetics, specifically making the titanium dioxide nanocomposite material prepared in Example 1 of the present invention into sunscreen, comprising the following steps:

[0055] Experimental group: phase A (in parts by mass, phase A includes 5 parts of lanolin, 4 parts of stearic acid, 2.5 parts of white petrolatum, 0.05 parts of propyl p-hydroxybenzoate, 8 parts of isooctyl salicylate), Phase B (in parts by mass, Phase B includes 70.3 parts of water, 5 parts of 1,2-propylene glycol, 1 part of triethanolamine, 0.1 part of methyl p-hydroxybenzoate, 0.05 part of disodium EDTA, 4 parts of Titanium dioxide nanocomposites) were heated to 80°C, and stirred continuously until all the ingredients were dissolved (except TiO 2 Outside), add phase A to phase B while stirring in a disperser, disperse evenly, cool to room temperature, and form a stable sunscreen. Apply the sunscreen lotion evenly on the surface of the ...

Embodiment 3

[0063] A kind of application of titanium dioxide nanocomposite material in wood, be specifically made the titanium dioxide nanocomposite material that makes in the embodiment of the present invention 1 anti-fading emulsion of stained wood, comprises the following steps:

[0064] Experimental group: 97 parts of water-based woodware PU emulsion (in parts by mass), 3 parts of titanium dioxide nanocomposite prepared in Example 1) were uniformly dispersed in a disperser at a speed of 4000r / min to form a stable wood anti-fading emulsion. Apply the wood fade-resistant emulsion evenly on the surface of the stained wood, and let it dry naturally to obtain the stained wood fade-resistant coating.

[0065] Control group 1: TiO prepared in comparative example 1 was added to the above formula 2 Nanoparticles, the other steps are the same.

[0066] Control group 2: the titanium dioxide nanocomposite material prepared in Example 1 was not added to the above formula, and its parts by weight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Primary particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com