Preparation method for bainite, martensite and austenite complex-phase corrosion-resistant steel

A technology of corrosion resistance and austenite zone, which is applied in the field of preparation of Bemao multiphase corrosion-resistant steel, can solve the problems of difficult temperature control, large amount of martensite, and difficulty in controlling the cooling rate of large-scale production products, etc. problems, to achieve the effect of easy control and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

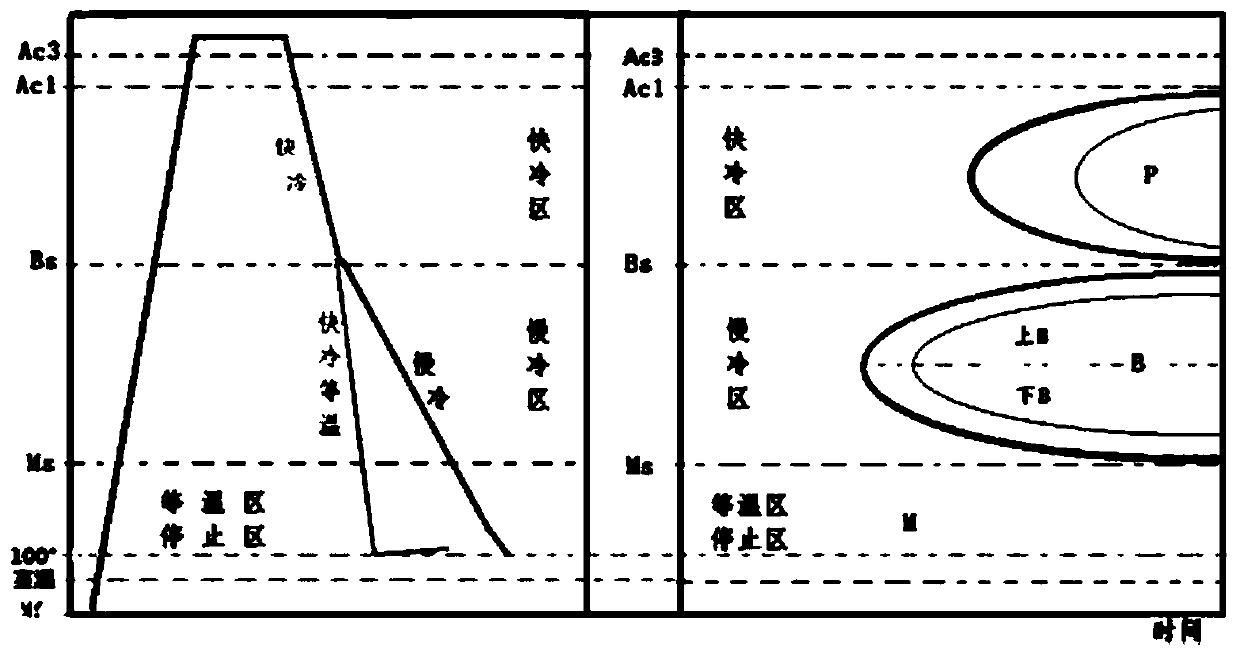

Method used

Image

Examples

Embodiment 1

[0050] The preparation process of a kind of Bemao composite anti-corrosive steel is as follows:

[0051] 1. According to the alloy mass percentage alloy of Example 1 in Table 1,

[0052] 2. After smelting the above alloy, perform online control of rolling ratio and temperature to roll 200mm billet, then perform rapid cooling to 200 degrees, and then heat up to 600 degrees for 2 hours and then cool to room temperature.

[0053] 3. Reheat the above-mentioned offline rolled products to 1200°C and hot-press with an abrasive tool to form the required product steel pipe or rail, then cool it to 650°C and keep it at room temperature for 4 hours.

[0054] 4. Heat the above-mentioned hot-formed steel products from room temperature to complete austenitization and heat preservation for 5 hours;

[0055] 5. Cool the above-mentioned steel products from austenite state directly with quenching liquid to 350 degrees, and then pile and cool to room temperature;

[0056] 6. After heating the above to 350 ...

Embodiment 2

[0059] The preparation process of a kind of Bemao composite anti-corrosive steel is as follows:

[0060] 1. According to the alloy mass percentage alloy of Example 2 in Table 1,

[0061] 2. After the above alloy is melted, the rolling ratio and temperature are controlled online to form a 300mm thick plate, then pile-cooled to room temperature, and then heated to 650 degrees for 4 hours and then cooled to room temperature.

[0062] 3. The above-mentioned offline rolled products are cold processed by mechanical equipment to make required products such as wheels and liners,

[0063] 4. The above-mentioned cold-formed steel products are heated to complete austenitization and heat preservation for 6 hours;

[0064] 5. Directly use quenching liquid to quickly cool the above-mentioned steel products from austenite state to 300°C and furnace cool to 100°C;

[0065] 6. After heating the above to 300°C for 3 hours, directly air cooling to room temperature is completed.

[0066] Obtaining effect: Th...

Embodiment 3

[0068] The preparation process of a kind of Bemao composite anti-corrosive steel is as follows:

[0069] 1. According to the alloying element mass percentage alloy of Example 3 in Table 1,

[0070] 2. After being smelted by conventional steelmaking process, it is casted by sand casting or precision casting process;

[0071] 3. Cool the castings formed by the above cast steel to 100 degrees;

[0072] 4. Reheat the above-mentioned casting products to 500±50°C for 4 hours, then heat up to 880°C for heat preservation, and then directly cool to 100°C for 4 hours with water.

[0073] 5. After heating the above to 350 degrees for 6 hours, directly air cooling to room temperature is completed.

[0074] Obtaining effect: The above process is suitable for large-section casting of corrosion-resistant steel, obtaining upper bainite and lower bainite with more martensite and more retained austenite, which is suitable for large cutting of materials, weak impact, corrosion electrochemical / chemical corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com