Petroleum sulfonate and preparation method thereof

A technology of petroleum sulfonate and petroleum sulfonic acid, which is applied in the direction of sulfonate preparation, sulfonic acid preparation, chemical instruments and methods, etc., can solve the problems of undisclosed raw material preparation process, etc., and achieve less gum and side reaction products The effect of formation, delaying catalyst poisoning, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

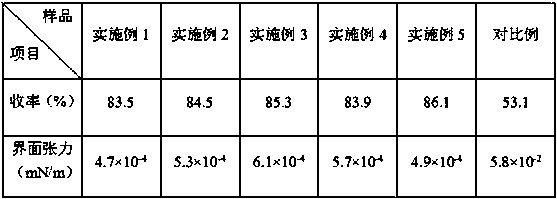

Examples

Embodiment 1

[0040] A petroleum sulfonate, which is prepared from the following components in parts by weight: 90 parts of crude oil, 10 parts of catalyst, 120 parts of potassium hydroxide solution with a mass concentration of 20%, hydrogen and sulfur trioxide The catalyst is composed of a carrier, an active metal and an auxiliary metal, the mass ratio of the carrier, the active metal and the auxiliary metal is 7:3:1, the carrier is macroporous alumina, the active metal is molybdenum oxide, and the auxiliary metal is sodium; The physical parameters of the catalyst are: porosity 0.1%, bulk density 0.3g / ml, average pore diameter 30nm, specific surface area 100cm 2 / g, the pore volume is 0.1cm 3 / g, the strength is 50N / mm.

[0041] Adopt above-mentioned raw material to prepare a kind of petroleum sulfonate, the preparation method of this petroleum sulfonate comprises the following steps:

[0042] (1) Send 90 parts of crude oil into the pipeline through a metering pump, feed hydrogen into th...

Embodiment 2

[0049] A petroleum sulfonate, which is prepared from the following components in parts by weight: 85 parts of straight-run distillate, 8 parts of catalyst, 110 parts of sodium hydroxide solution with a mass concentration of 25%, hydrogen and three Sulfur oxide; the catalyst is composed of carrier, active metal and auxiliary metal, the mass ratio of carrier, active metal and auxiliary metal is 9:5:1, the carrier is macroporous alumina, the active metal is cobalt oxide, and the auxiliary metal is Magnesium; the physical parameters of the catalyst are: the porosity is 0.2%, the bulk density is 0.4g / ml, the average pore diameter is 40nm, and the specific surface area is 200cm 2 / g, the pore volume is 0.3cm 3 / g, the strength is 80N / mm.

[0050] Adopt above-mentioned raw material to prepare a kind of petroleum sulfonate, the preparation method of this petroleum sulfonate comprises the following steps:

[0051] (1) Send 85 parts of straight-run distillate into the pipeline through...

Embodiment 3

[0058] A petroleum sulfonate, which is prepared from the following components in parts by weight: 75 parts of furfural extraction oil, 5 parts of catalyst, 100 parts of potassium hydroxide solution with a mass concentration of 35%, hydrogen and three Sulfur oxide; the catalyst is composed of carrier, active metal and auxiliary metal, the mass ratio of carrier, active metal and auxiliary metal is 8.5:4:1, the carrier is macroporous alumina, the active metal is nickel oxide, and the auxiliary metal is Iron; the physical parameters of the catalyst are: the porosity is 0.45%, the bulk density is 0.65g / ml, the average pore diameter is 65nm, and the specific surface area is 300cm 2 / g, the pore volume is 0.8cm 3 / g, the strength is 150N / mm.

[0059] Adopt above-mentioned raw material to prepare a kind of petroleum sulfonate, the preparation method of this petroleum sulfonate comprises the following steps:

[0060] (1) Send 75 parts of furfural extracted oil into the pipeline throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com