Polyimide composite film and preparation method thereof

A technology of composite film and polyimide, applied in chemical instruments and methods, flat products, other household appliances, etc., to achieve good combination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

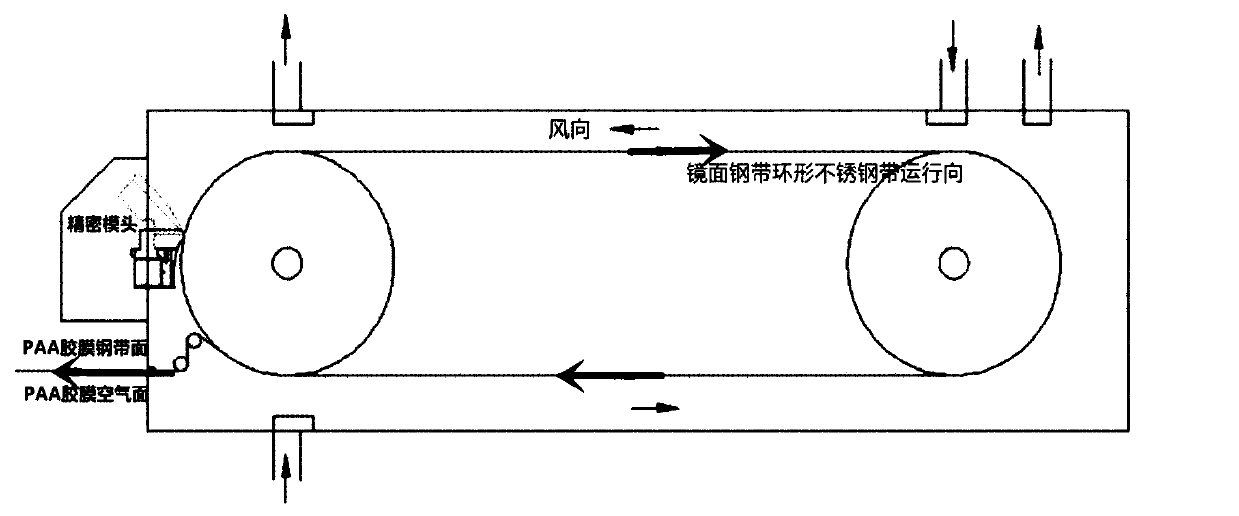

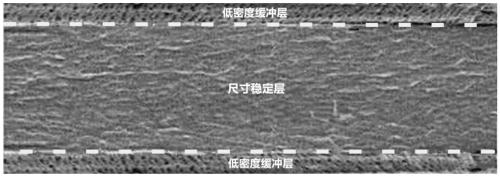

Method used

Image

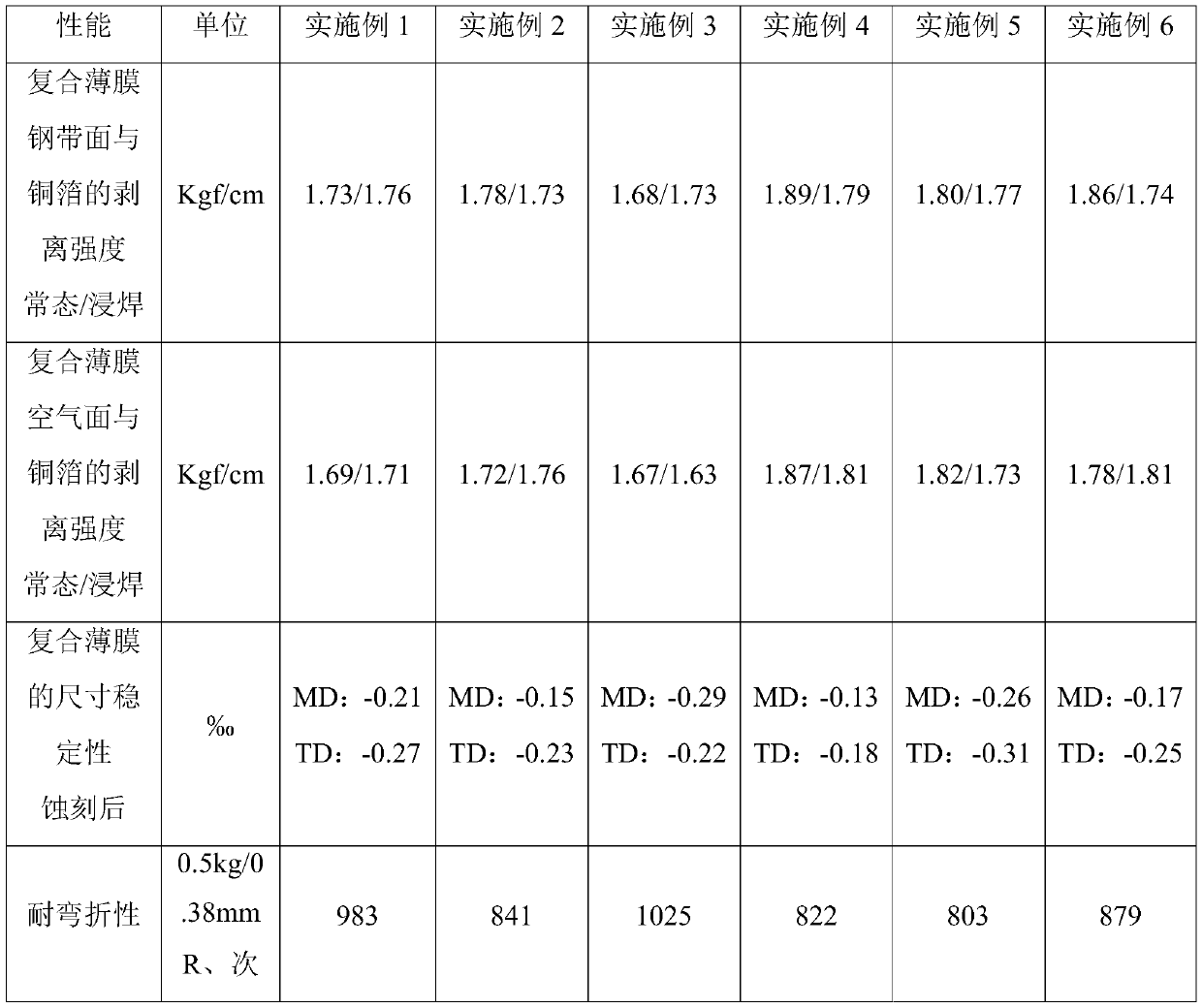

Examples

Embodiment 1

[0078] The preparation method of polyimide composite film comprises the following steps:

[0079] (1) Under the condition of normal pressure filled with nitrogen in the stirred tank at 35°C, first dissolve 4,4'-diaminodiphenyl ether and p-phenylenediamine in dimethylacetamide solvent, and then add pyromellitic tetra Formic acid dianhydride is polymerized, and the reaction time is 4 hours. The molar ratio of pyromellitic dianhydride: 4,4'-diaminodiphenyl ether: p-phenylenediamine is 1.00:0.50:0.502, and the average particle size is 3 μm Ultrasonic mixing of mica powder pre-dispersion, the amount of mica powder added accounted for 1wt% of the total amount of dianhydride monomers and diamine monomers, to obtain polyamic acid glue A;

[0080] (2) Under the condition of normal pressure filled with nitrogen in the stirred tank at 35°C, first dissolve 4,4'-diaminodiphenyl ether and p-phenylenediamine in dimethylacetamide solvent, and then add pyromellitic tetra Formic acid dianhydri...

Embodiment 2

[0085] The preparation method of polyimide composite film comprises the following steps:

[0086] (1) Under the condition of normal pressure filled with nitrogen in the stirred tank at 35°C, first dissolve 4,4'-diaminodiphenyl ether and p-phenylenediamine in dimethylacetamide solvent, and then add pyromellitic tetra Formic acid dianhydride is polymerized, and the reaction time is 4 hours. The molar ratio of pyromellitic dianhydride: 4,4'-diaminodiphenyl ether: p-phenylenediamine is 1.00:0.50:0.502, and the average particle size is 2 μm Ultrasonic mixing of mica powder pre-dispersion, the amount of mica powder added accounted for 2wt% of the total amount of dianhydride monomers and diamine monomers, to obtain polyamic acid glue A;

[0087] (2) Under the condition of normal pressure filled with nitrogen in the stirred tank at 35°C, first dissolve 4,4'-diaminodiphenyl ether and p-phenylenediamine in dimethylacetamide solvent, and then add pyromellitic tetra Formic acid dianhydri...

Embodiment 3

[0092] The preparation method of polyimide composite film comprises the following steps:

[0093] (1) Under the condition of normal pressure filled with nitrogen in the stirred tank at 35°C, first dissolve 4,4'-diaminodiphenyl ether and p-phenylenediamine in dimethylacetamide solvent, and then add pyromellitic tetra Formic acid dianhydride is polymerized, and the reaction time is 4 hours. The molar ratio of pyromellitic dianhydride: 4,4'-diaminodiphenyl ether: p-phenylenediamine is 1.00:0.50:0.502, and the average particle size is 6 μm Ultrasonic mixing of mica powder pre-dispersion, the amount of mica powder added accounted for 1wt% of the total amount of dianhydride monomers and diamine monomers, to obtain polyamic acid glue A;

[0094] (2) Under the condition of normal pressure filled with nitrogen in the stirred tank at 35°C, first dissolve 4,4'-diaminodiphenyl ether and p-phenylenediamine in dimethylacetamide solvent, and then add pyromellitic tetra Formic acid dianhydri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com