Surface modified metal powder with high laser reflectivity and 3D printing method

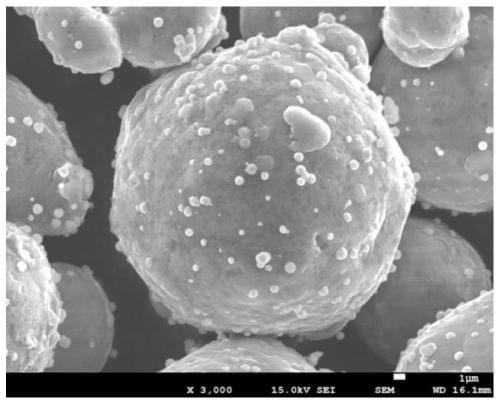

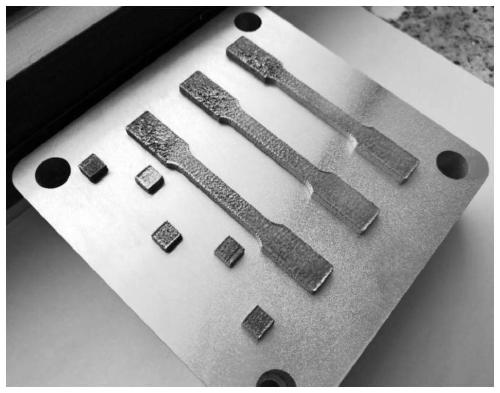

A technology of laser reflection and surface modification, which is applied in the 3D printing of copper and powder after surface modification, the surface modification coating of aluminum alloy or copper alloy powder, and the aluminum field, which can solve the problem of many pores and defects, laser Problems such as high reflectivity and poor molding ability can achieve the effect of low production cost, simple process and reduced defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Prepare nickel-phosphorus-coated pure aluminum surface modification coating powder with nickel content of about 5% and phosphorus content of about 0.5%, and the molar concentration of sodium citrate, nickel chloride, and sodium hypophosphite in the plating solution Respectively 0.15mol / L, 0.15mol / L and 0.3mol / L, calculate the sodium citrate that needs to add in the plating solution, nickel chloride, the quality of sodium hypophosphite is respectively 63.97g, 51.69g and 46.11g, All are analytically pure. Put sodium citrate and nickel chloride into two beakers and dissolve them with 700mL of deionized water, then pour the nickel chloride solution into the sodium citrate solution, and keep stirring to make them fully complexed. Put the electronic pH meter into the beaker containing the mixed solution, add 3mol / L NaOH solution while stirring, adjust the pH to 11~12, add deionized water until the volume of the plating solution reaches 1450mL, put sodium hypophosphite Add...

Embodiment 2

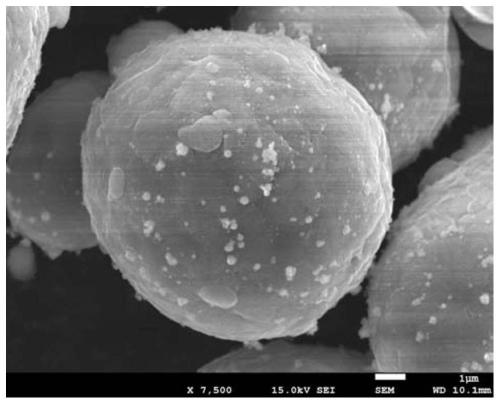

[0046] The difference between this Example 2 and Example 1 is that the reducing agent is changed from sodium hypophosphite to sodium borohydride, that is, to change the trace elements in the metal coated on the surface of aluminum or aluminum alloy powder, and to change the nickel-phosphorous Change to nickel-boron coating with about 3% nickel and 0.3% boron. Other main parameters are changed as follows: the molar concentrations of sodium citrate, nickel chloride and sodium borohydride are 0.095mol / L, 0.095mol / L and 0.2mol / L, and the sodium citrate, chloride The masses of nickel and sodium borohydride are 22.58g, 27.94g and 10.97g respectively. The complexing agent and metal salt were dissolved in 400mL of deionized water respectively, the concentration of the added KOH alkaline solution was 2mol / L, the pH was adjusted to 9-10, the final volume of the plating solution was 950mL, and the reducing agent was prepared as 50mL. Add 100g of pure aluminum powder with a particle size...

Embodiment 3

[0049] The difference between this embodiment 3 and embodiment 1 is that the metal salt is changed from nickel chloride to ferrous sulfate, and the reducing agent is changed from sodium hypophosphite to hydrazine hydrate, that is, the surface coating of aluminum or aluminum alloy powder is changed. The content of metals and their trace elements is changed from coated nickel phosphorus to coated pure iron, and the iron content is about 0.1%. In addition, when using hydrazine hydrate as a reducing agent, due to the toxicity of hydrazine hydrate, it is necessary to take corresponding protective measures, wear a gas mask, protective glasses and gloves, and pass the generated waste gas into a dilute hydrogen peroxide solution to react the hydrazine hydrate vapor and then discharge it. into the atmosphere. Other main parameters are changed as follows: the molar concentrations of sodium citrate, ferrous sulfate, and hydrazine hydrate are 0.005mol / L, 0.005mol / L and 0.01mol / L, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com