Organic thin film transistor and preparation method thereof

An organic thin film and transistor technology, applied in the field of organic thin film transistors and their preparation, can solve problems such as damage to the surface of a flat layer, and achieve the effects of increasing carrier mobility, reducing production costs, and improving manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

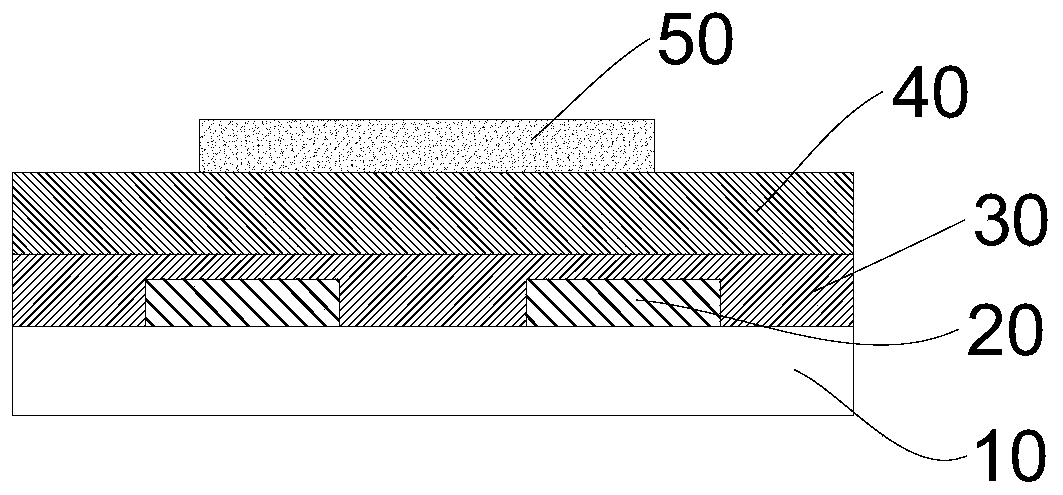

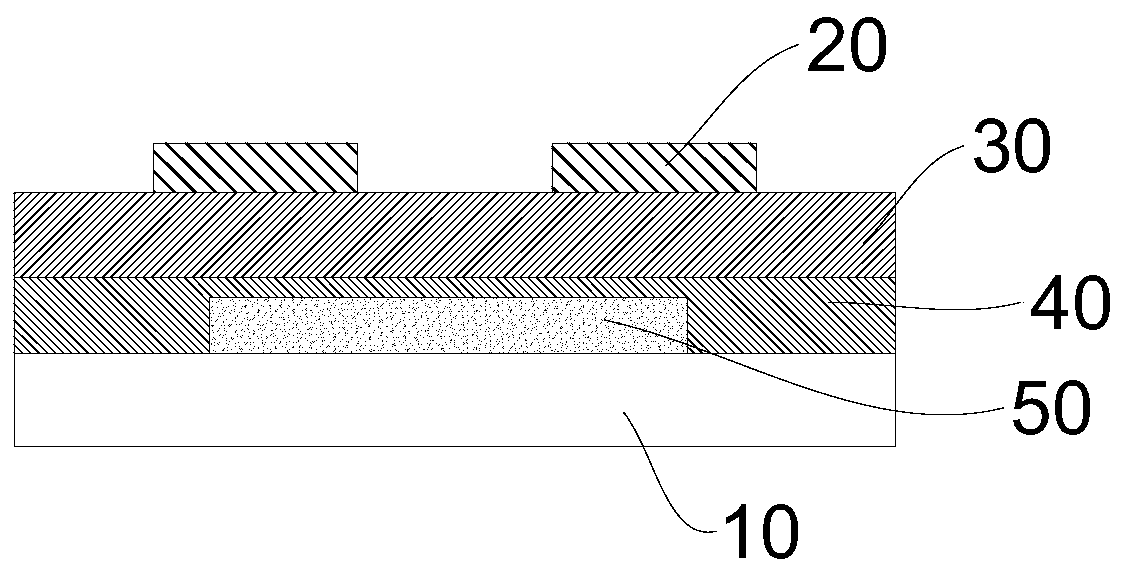

[0039] Organic thin film transistor (wherein, the electrode layer close to substrate 10 is source drain layer 20, refer to figure 1 ) preparation method, comprising the steps of:

[0040] (1) Select the substrate 10 , such as a glass substrate, a silicon substrate or a flexible substrate. Among them, the flexible substrate can be: PI (polyimide) substrate, PET (polyethylene terephthalate) substrate, PEN (polyethylene naphthalate) substrate, PES (polyethersulfone) substrate , PC (polycarbonate) substrate, PVA (polyvinyl alcohol) substrate, PP (polypropylene) substrate, MYLAR film substrate, PEEK (polyether ether ketone) substrate, PPA (polyparaphenylene terephthalamide) substrate , PTFE (polytetrafluoroethylene) substrate, PMMA (polymethyl methacrylate) substrate, PDMS (polydimethylsiloxane) substrate, etc.

[0041] In this embodiment, the shape and thickness of the substrate 10 are not limited, as long as the organic thin film transistor can be prepared. Furthermore, if the...

Embodiment 1

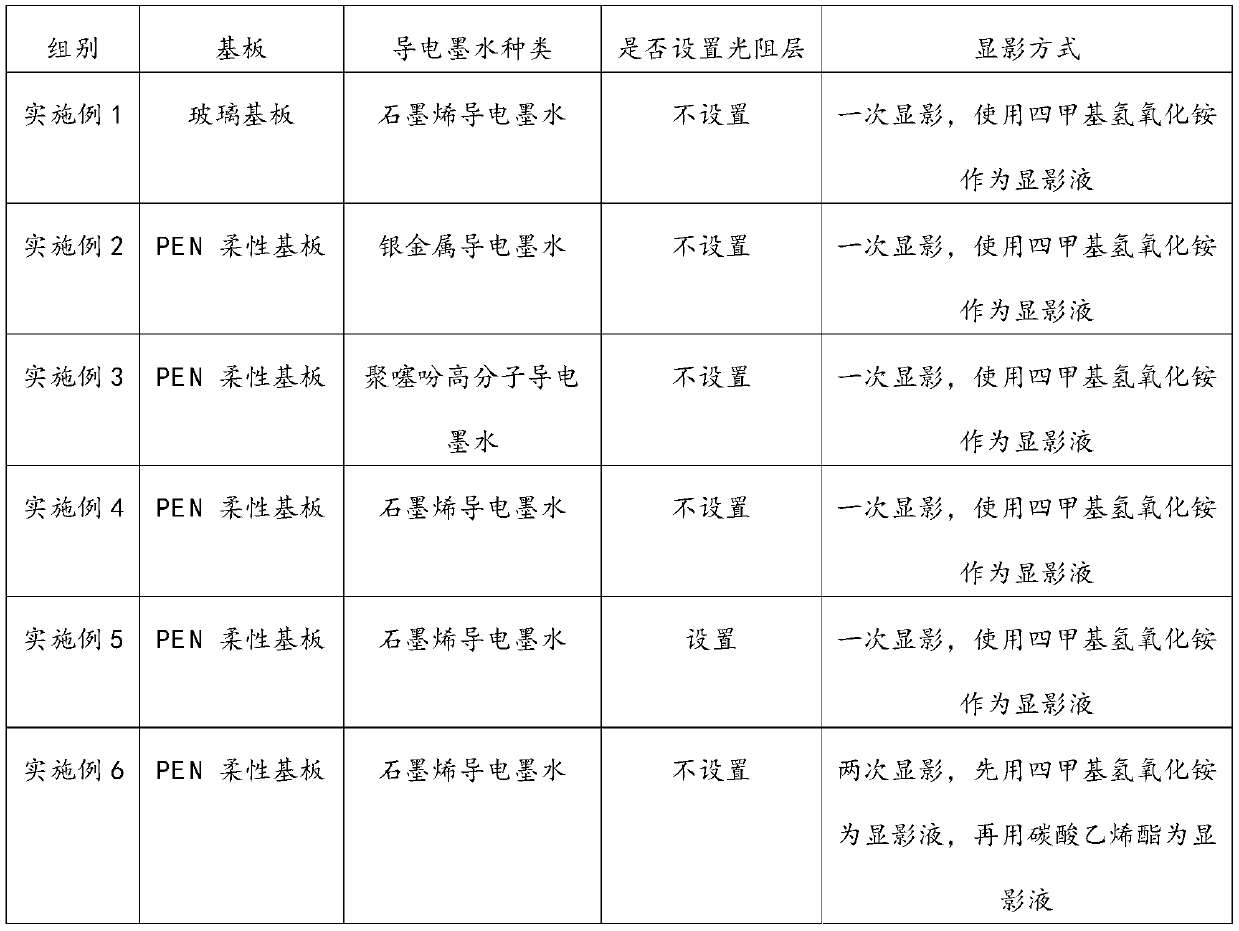

[0077] The comparison between Example 1 and Example 4 shows that compared with the glass substrate, the electrical performance of the organic thin film transistor obtained by coating the graphene conductive ink on the PEN flexible substrate is better.

Embodiment 2

[0078] Embodiment 2, embodiment 3 and embodiment 4 compare illustration, compare with silver metal conductive ink and polythiophene polymer conductive ink, on PEN flexible substrate, coat graphene conductive ink, the electrical performance of the organic thin film transistor that obtains better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com