Treatment agent for coupling treatment of various heavy metal ions in electroplating wastewater

A technology for heavy metal ions and electroplating wastewater, which is applied in the direction of precipitation treatment, metallurgical wastewater treatment, adsorption water/sewage treatment, etc. It can solve the problem that the treatment technology is difficult to meet the development needs of the industry, the price of the adsorbent is high, and the bacteria and microorganisms are resistant to heavy metals and have low toxicity. problems such as reducing effectiveness and migration activity, overcoming antagonism or competition, and inhibiting enrichment and translocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

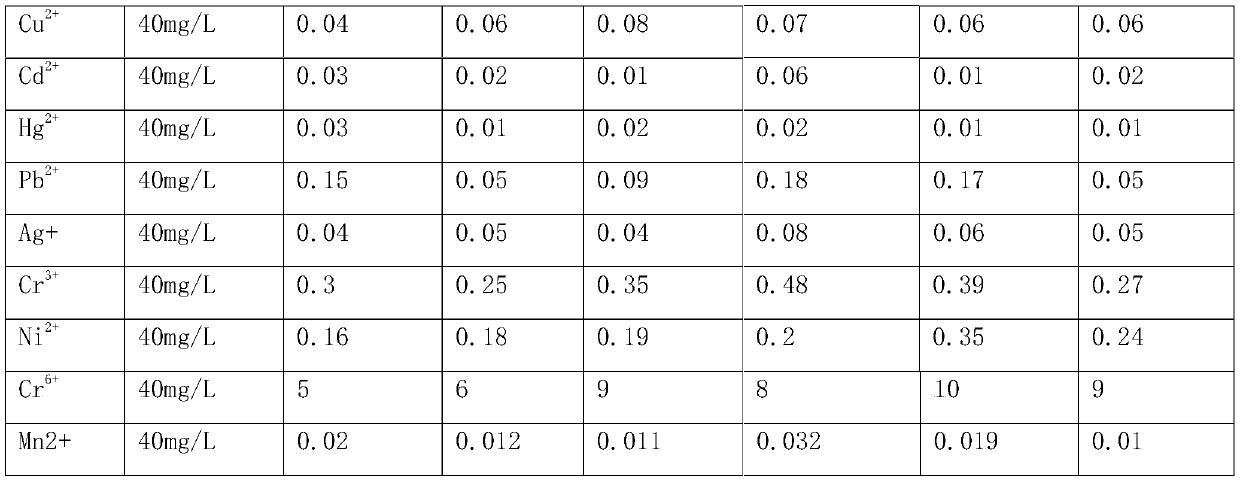

Examples

Embodiment 1

[0021] The treatment agent used for the coupling treatment of multiple heavy metal ions in electroplating wastewater in this embodiment, the raw material of the treatment agent includes the following components in parts by weight: 20 parts of olive pomace, 10 parts of olive sawdust, and 5 parts of nitro humic acid resin , 5 parts of ethoxylated polyethyleneimine, 4 parts of biochar, 3 parts of cetylpyridinium chloride, 3 parts of starch xanthate, 5 parts of sodium polyacrylate, 1 part of crosslinking agent, sulfonated sulfur 5 parts of heterocalixarene, 5 parts of octylphenyl polyoxyethylene ether, 4 parts of modified sericin, 2 parts of polyaspartic acid, 3 parts of β-cyclodextrin, 1 part of organic polymer coagulant, 1 part of agent, 2 parts of poly(diallylammonium chloride-acrylamide) based sodium dithiocarbamate;

[0022] Wherein, the organic polymer coagulant is prepared in the following manner: a. dissolving sodium silicate in distilled water, adjusting the pH value belo...

Embodiment 2

[0034]The treatment agent used for coupling treatment of multiple heavy metal ions in electroplating wastewater in this embodiment, the raw material of the treatment agent includes the following components in parts by weight: 30 parts of olive pomace, 20 parts of olive sawdust, 15 parts of nitro humic acid resin , 15 parts of ethoxylated polyethyleneimine, 12 parts of biochar, 8 parts of cetylpyridinium chloride, 8 parts of starch xanthate, 10 parts of sodium polyacrylate, 3 parts of crosslinking agent, sulfonated sulfur 10 parts of heterocalixarene, 10 parts of octylphenyl polyoxyethylene ether, 8 parts of modified sericin, 6 parts of polyaspartic acid, 9 parts of β-cyclodextrin, 5 parts of organic polymer coagulant, 4 parts of agent, 8 parts of poly(diallylammonium chloride-acrylamide) based sodium dithiocarbamate;

[0035] Wherein, the organic polymer coagulant is prepared in the following manner: a. dissolving sodium silicate in distilled water, adjusting the pH value belo...

Embodiment 3

[0047] The treatment agent used for the coupling treatment of multiple heavy metal ions in electroplating wastewater in this embodiment, the raw material of the treatment agent includes the following components in parts by weight: 20 parts of olive pomace, 20 parts of olive sawdust, 5 parts of nitro humic acid resin , 15 parts of ethoxylated polyethyleneimine, 4 parts of biochar, 8 parts of cetylpyridinium chloride, 3 parts of starch xanthate, 10 parts of sodium polyacrylate, 1 part of crosslinking agent, sulfonated sulfur 10 parts of heterocalixarene, 5 parts of octylphenyl polyoxyethylene ether, 8 parts of modified sericin, 2 parts of polyaspartic acid, 9 parts of β-cyclodextrin, 1 part of organic polymer coagulant, 4 parts of agent, 2 parts of poly(diallylammonium chloride-acrylamide) based sodium dithiocarbamate;

[0048] Wherein, the organic polymer coagulant is prepared in the following manner: a. dissolving sodium silicate in distilled water, adjusting the pH value belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com