Giant dielectric composite ceramic copper calcium titanate material and preparation method and application thereof

A technology of copper calcium titanate and composite ceramics, which is applied in the direction of circuits, capacitors, electrical components, etc., can solve the problems of less research and further improvement, and achieve the effects of good repeatability, simple and controllable preparation process, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

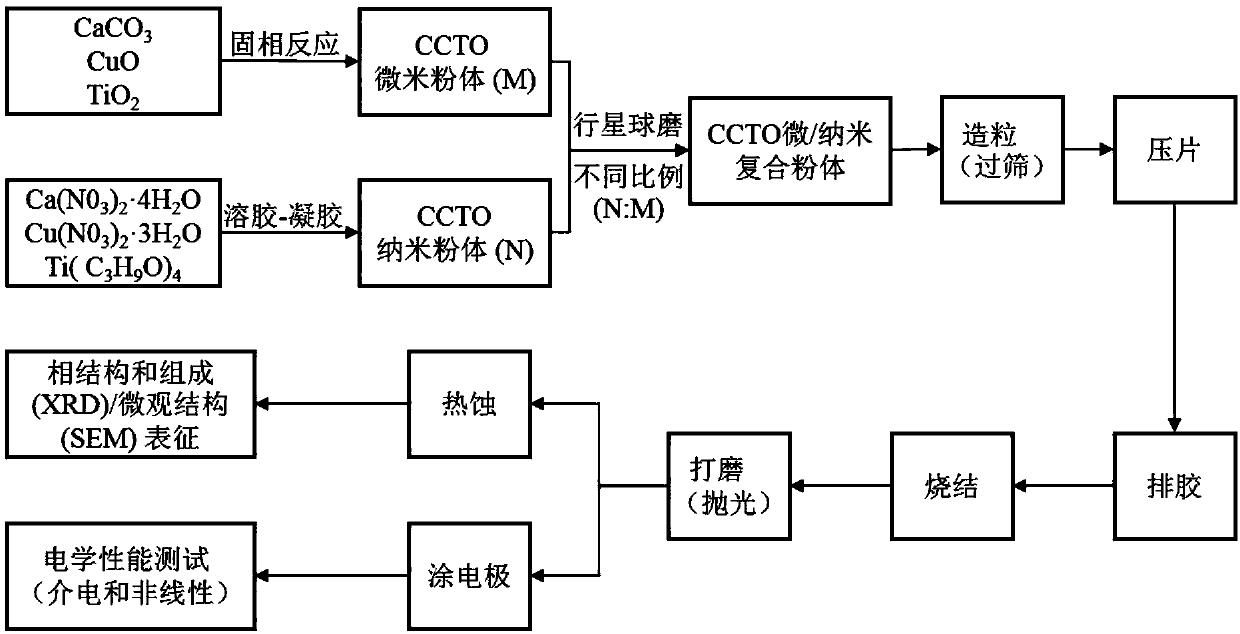

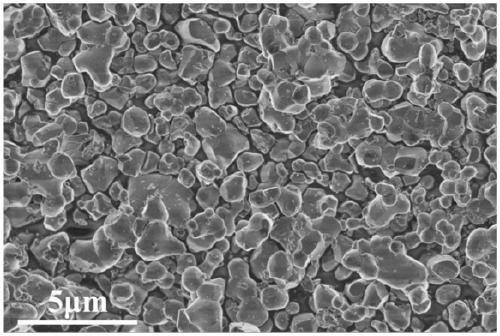

[0051] A preparation method of a giant dielectric copper calcium titanate composite ceramic material with high energy storage density is carried out according to the following steps:

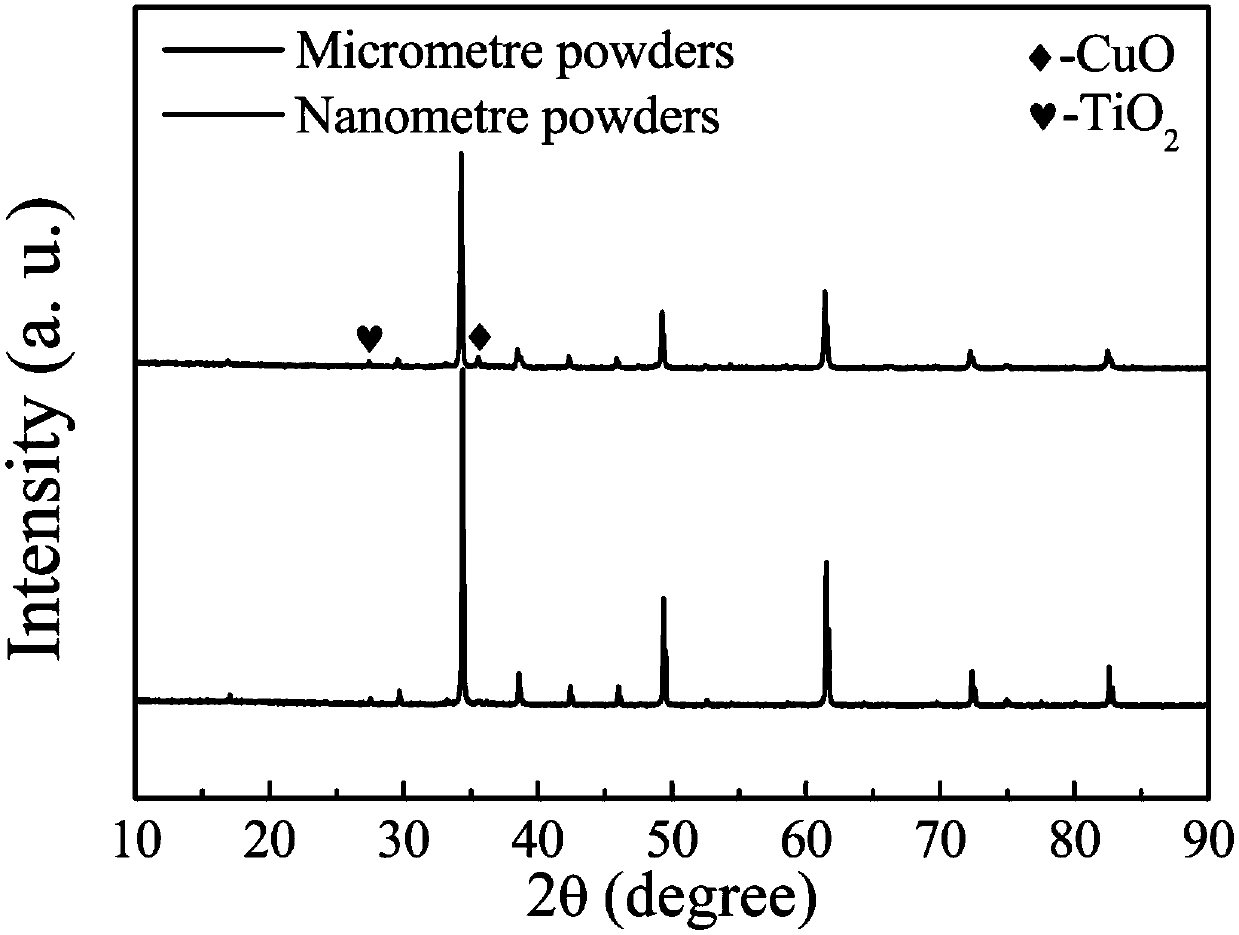

[0052] (1) Preparation of copper calcium titanate micron powder (M)

[0053] a. Press CaCu 3 Ti 4 o 12 The stoichiometric ratio of the substances were weighed CaCO 3 7.6g, CuO 18.125g and TiO 2 24.275g;

[0054] b, the CaCO weighed in step a 3 , CuO and TiO 2 After mixing the raw materials, put them into a ball mill jar, then add 60mL of absolute ethanol and agate balls as a ball milling medium, place them in a planetary ball mill for ball milling, and mill at a speed of 500r / min for 12 hours;

[0055] c. Put the mixed solution after ball milling on an evaporating dish, place it in a drying oven, and dry it at 80°C for 10 hours to obtain the CCTO precursor powder;

[0056] d. Fully grind the dried CCTO precursor powder and pass through an 80-mesh sieve, then put it into an alumina cruci...

Embodiment 2

[0070] The difference from Example 1 is that in this example, in step (3), the ratio (N:M) of CCTO nanopowder to CCTO micropowder is 0.5:0.5 and weighs 10g of nanometer and 10g of micron powder After mixing, put it into a ball mill jar, then add 30mL of absolute ethanol and agate balls as a ball milling medium, place it in a planetary ball mill, and mill it at a speed of 550r / min for 12h.

[0071] Other steps are the same as in Example 1 to obtain a CCTO composite ceramic sample.

Embodiment 3

[0073] The difference from Example 1 is that in this example, in step (3), the ratio (N:M) of CCTO nanopowder to micron powder is 0.7:0.3, and 14g of nanometer and 6g of micron powder are weighed and mixed. Put it into a ball mill jar, add 30 mL of absolute ethanol and agate balls as a ball milling medium, place it in a planetary ball mill, and mill it at a speed of 550 r / min for 12 hours.

[0074] Other steps are the same as in Example 1 to obtain a CCTO composite ceramic sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com