Poly-ionic-liquid-modified cerium-doped nano zinc oxide photocatalyst and preparation method and application thereof

A polyionic liquid, nano-zinc oxide technology, applied in catalyst activation/preparation, physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, etc., can solve the problem of long reaction time, high cost and reaction cost Advanced problems, to achieve high photocatalytic efficiency and visible light activity, short production process, simple operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

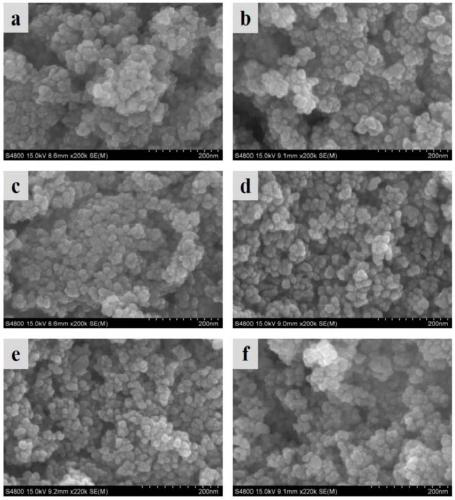

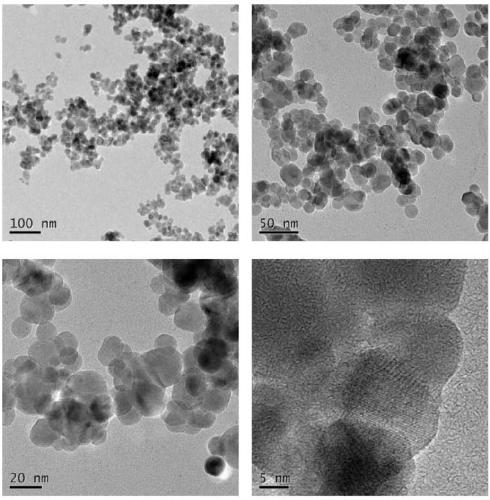

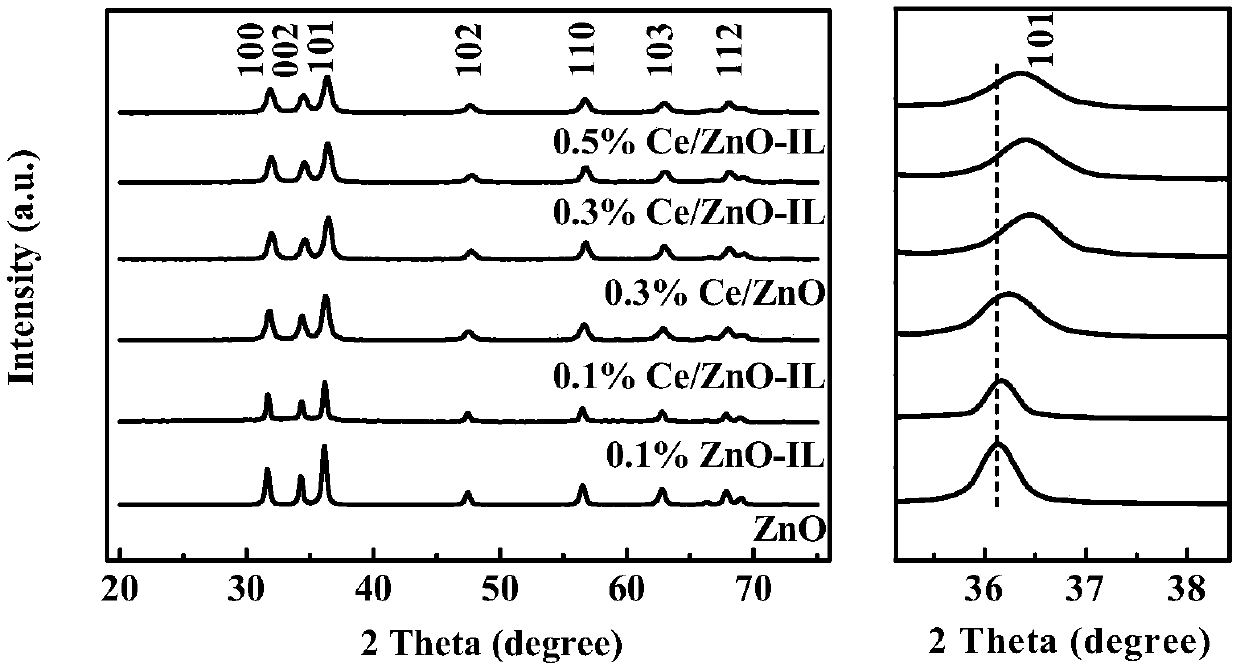

Embodiment 1

[0035] Weigh 1.7890g of zinc nitrate hexahydrate, 2.5308g of hexamethylenetetramine, and 0.4820g of sodium citrate dihydrate into a 500mL three-necked flask, add 250mL of deionized water, stir at room temperature until the solid dissolves, and obtain a clear Transparent mixed solution; place the three-necked flask containing the above mixed solution in a constant temperature magnetic stirring water bath, react at 90°C for 2 hours, then centrifuge and wash with water for 3 times and ethanol for 2 times, then filter with suction , put the obtained solid in a drying oven with a set temperature of 60°C for 24 hours, and grind it for 0.5 hours after drying to obtain a powdery solid; put the above solid into a crucible and place it in a muffle furnace to control the temperature at 400 After calcination treatment at ℃ for 3 hours, nano zinc oxide powder (also known as cerium-doped nano zinc oxide photocatalyst) is obtained.

Embodiment 2

[0037] Weigh 1.7890g of zinc nitrate hexahydrate, 2.5308g of hexamethylenetetramine, 0.4820g of sodium citrate dihydrate and 0.0010g of polyionic liquid in a 500mL three-necked flask, add 250mL of deionized water, and Stir until the solid dissolves to obtain a clear and transparent mixed solution; place the three-necked flask containing the above mixed solution in a constant temperature magnetic stirring water bath, react at 85°C for 3 hours, then centrifuge and wash with water for 3 times, wash with ethanol Wash twice, then filter with suction, place the obtained solid in a drying oven set at a temperature of 50°C for 30 hours, and grind for 0.5 hours after drying to obtain a powdery solid; put the above solid into a crucible, The nanometer zinc oxide powder was obtained after roasting at 300° C. for 3 hours in a furnace.

Embodiment 3

[0039] Weigh 1.7890g of zinc nitrate hexahydrate, 2.5308g of hexamethylenetetramine, 0.4820g of sodium citrate dihydrate, 0.0013g of hexahydrate of cerium nitrate and 0.0010g of polyionic liquid in a 500mL three-necked flask, Add 250mL of deionized water, stir at room temperature until the solid dissolves, and obtain a clear and transparent mixed solution; place the three-necked flask containing the above mixed solution in a constant temperature magnetic stirring water bath, react at 85°C for 3h, then centrifuge and Wash 3 times with water and 2 times with ethanol, then filter with suction, place the obtained solid in a drying oven with a set temperature of 50°C for 30 hours, and grind for 0.5 hours after drying to obtain a powdery solid; Put it into a crucible, and bake it in a muffle furnace at 250° C. for 3 hours to obtain nanometer zinc oxide powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com