Graphene polyurethane sponge and application thereof

A technology of polyurethane sponge and graphene, which is applied in electrical components, magnetic field/electric field shielding, etc., can solve the problems of frequency bandwidth of only 2.62GHz, decrease of wave-absorbing performance, and affect waterproof effect, etc., so as to improve wave-absorbing performance and service life , reduce reflectivity, solve the effects of shedding and water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

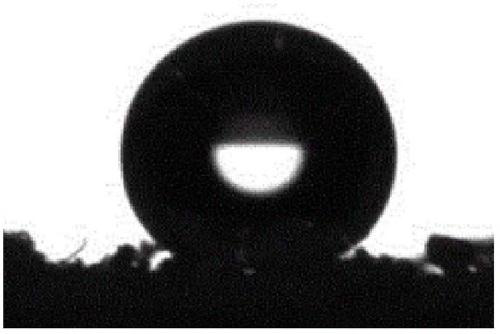

Image

Examples

preparation Embodiment 1

[0044] Preparation of graphene dispersion:

[0045] Preparation of secondary expanded graphite: Put 5g of graphite into a 500mL three-necked flask, immerse the three-necked flask in the ice-water mixture, then add 45mL of concentrated nitric acid and 87.5mL of concentrated sulfuric acid, and slowly add 55g of potassium chlorate to the three-necked flask Medium (adding time is at least more than 15 minutes. Note: Chlorine dioxide will be produced when potassium chlorate is added, and an explosion will occur when the concentration is high), this process is stirred for 72 hours, and the treated graphite is washed into neutrality with a large amount of water, and dried Finally, the powder is obtained; then the oxidized graphite is placed in a tube furnace, and the expansion time is 30 seconds to 5 minutes and the temperature is 1000-1300°C, and the high temperature reduction is carried out to obtain the primary expanded graphite, and the primary expanded graphite is treated by th...

Embodiment 1

[0048] The graphene dispersion was prepared in the same manner as in Preparation Example 1 except that N,N-dimethylcyclohexylamine was used as the dispersion medium.

[0049] Graphene polyurethane sponge is formed by foaming the following raw materials, and the parts by weight of each component are:

[0050] 100 parts of polyether 560D, 0.15 part of catalyst A1, 0.34 part of catalyst stannous octoate, 1.2 parts of silicone oil L580, 3 parts of water, 10 parts of graphene N,N-dimethylcyclohexylamine dispersion (the content of graphene is 10%), 5 parts of N,N-dimethylcyclohexylamine dispersion of hydroxyl iron powder (5% content of hydroxyl iron powder), and 48.3 parts of toluene diisocyanate TDI-80.

[0051] The foaming method is as follows:

[0052] Control the ambient temperature at 21°C, weigh the above polyether, catalyst, water, foam stabilizer, graphene dispersion and hydroxyl iron powder dispersion according to the formula, add them to the material bucket, and mix and s...

Embodiment 2

[0054] A graphene dispersion was prepared in the same manner as in Preparation Example 1 except that bis(2-dimethylaminoethyl) ether was used as the dispersion medium.

[0055] Graphene polyurethane sponge is formed by foaming the following raw materials, and the parts by weight of each component are:

[0056] Bis(2-dimethylaminoethyl) ether dispersion (( The content of graphene is 10%), 10 parts of triethylamine dispersion liquid of hydroxyl iron powder (the content of hydroxyl iron powder is 8%), and 30 parts of hexamethylene diisocyanate.

[0057] The foaming method is as follows:

[0058] Control the ambient temperature at 20°C, weigh the above polyether, catalyst, foam stabilizer, water, silicone oil, graphene dispersion, and hydroxyl iron powder dispersion according to the formula and add them to the material bucket, and use a mixer (speed 1000rad / min) Mix and stir for 30s, let it stand for 4min, then weigh the toluene diisocyanate and pour it into the material mixing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical bandwidth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com