Phosphating solution and phosphating method for aluminum alloy surface treatment

A technology of aluminum alloy surface and aluminum alloy, which is applied in the direction of metal material coating process, etc., can solve the problems of heavy film, high service temperature, complex composition, etc., and achieve uniform and dense film, good corrosion resistance and low processing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

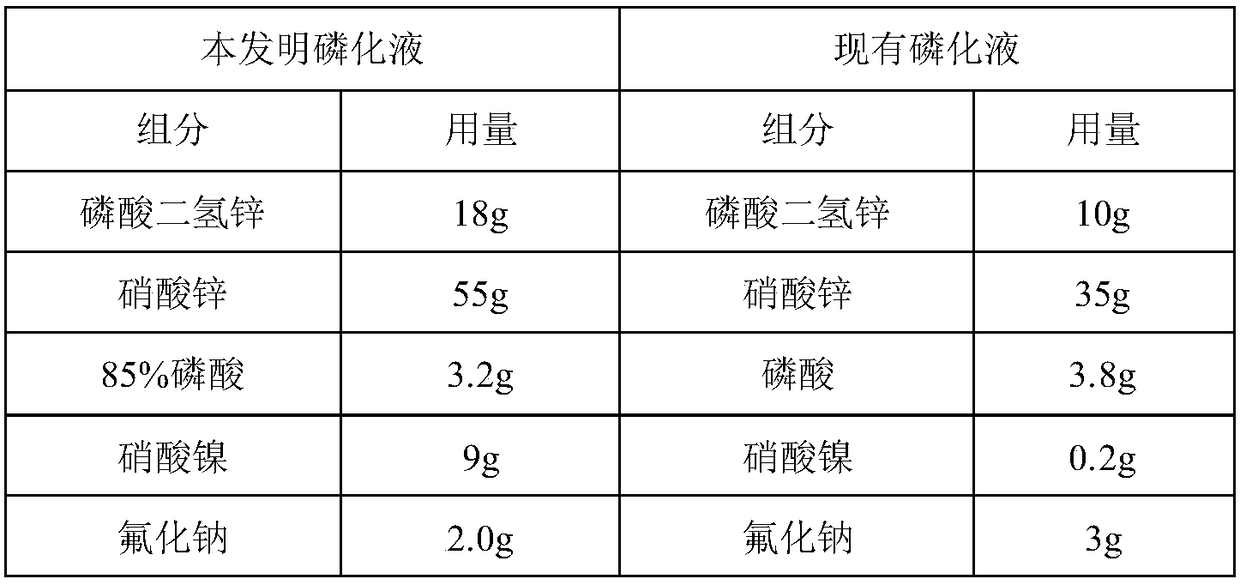

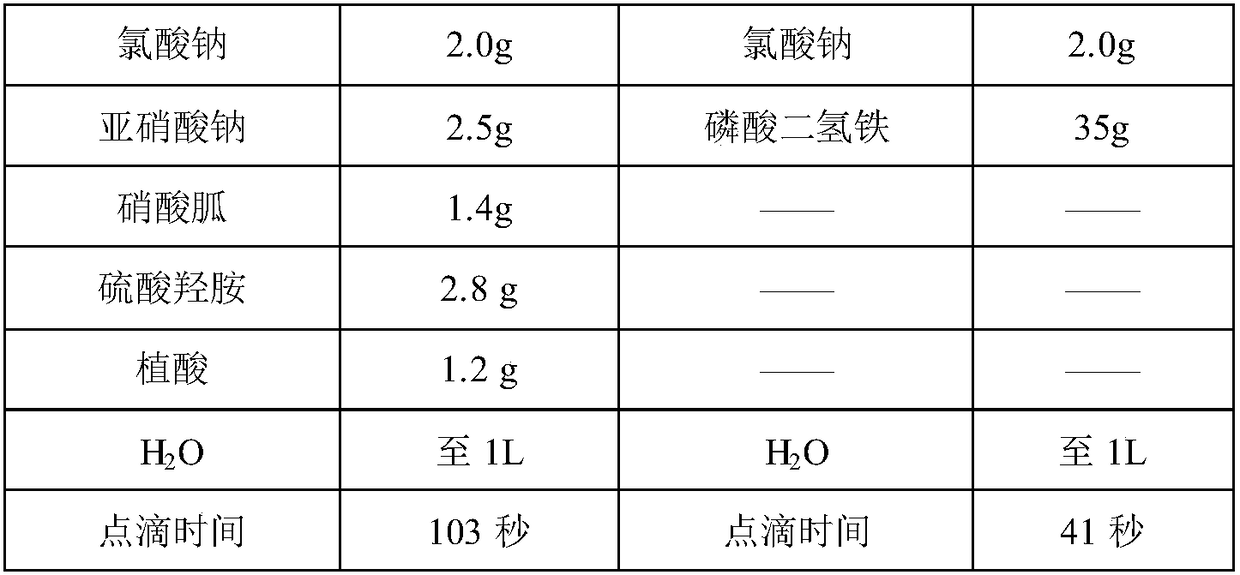

Embodiment 1

[0021] The formula that adopts phosphating solution in the present embodiment is: zinc dihydrogen phosphate 18g, zinc nitrate 55g, 85% phosphoric acid 3.2g, nickel nitrate 9g, sodium fluoride 2.0g, sodium chlorate 2.0g, sodium nitrite 2.5g, Guanidine nitrate 1.4g, hydroxylamine sulfate 2.8g, phytic acid 1.2g. Dissolve the above compounds in deionized water, prepare 1 liter of phosphating solution, and adjust the pH value to 3.5-3.7 with 1 mol / L sodium hydroxide solution.

[0022] Phosphating method: grind and polish the aluminum alloy sheet with No. 240, No. 360, No. 600, and No. 1200 water-grinding sandpaper in sequence, degrease with acetone, and clean with deionized water; then immerse the aluminum alloy test piece in a concentration of 1.0mol / L , washed with alkali at a temperature of 65°C for 50 seconds to remove the natural oxide film, immediately immersed in 1.0mol / L nitric acid solution for neutralization for 20 seconds after taking it out, rinsed with deionized water,...

Embodiment 2

[0025] The formula that adopts phosphating solution in the present embodiment is: zinc dihydrogen phosphate 20g, zinc nitrate 50g, 85% phosphoric acid 3.0g, nickel nitrate 8g, sodium fluoride 2.2g, sodium chlorate 1.8g, sodium nitrite 3.0g, Guanidine nitrate 1.2g, hydroxylamine sulfate 3.0g, phytic acid 1.5g. Dissolve the above compounds in deionized water, prepare 1 liter of phosphating solution, and adjust the pH value to 3.5-3.7 with 1 mol / L sodium hydroxide solution.

[0026] Phosphating method: the pre-treatment and post-treatment processes of the aluminum alloy are exactly the same as the above-mentioned embodiment 1. The difference is: the phosphating process controls the reaction temperature to 50°C, and the phosphating reaction time is controlled to 10 minutes.

[0027] The phosphating film on the surface of the phosphating aluminum alloy is tested, the appearance is gray-black, uniform and dense, the film is thin, and the film weight is 3.5g / m 2 ; Copper sulfate dr...

Embodiment 3

[0029] The formula that adopts phosphating solution in the present embodiment is: zinc dihydrogen phosphate 23g, zinc nitrate 60g, 85% phosphoric acid 3.0g, nickel nitrate 6g, sodium fluoride 2.5g, sodium chlorate 1.5g, sodium nitrite 2.8g, Guanidine nitrate 1.5g, hydroxylamine sulfate 3.2g, phytic acid 1.0g. Dissolve the above compounds in deionized water, prepare 1 liter of phosphating solution, and adjust the pH value to 3.5-3.7 with 1 mol / L sodium hydroxide solution.

[0030] Phosphating method: the pre-treatment and post-treatment processes of the aluminum alloy are exactly the same as the above-mentioned embodiment 1. The difference is that the phosphating process controls the reaction temperature to 45°C, and the phosphating reaction time is controlled to 15 minutes.

[0031] The phosphating film on the surface of the phosphating aluminum alloy is tested, the appearance is gray-black, uniform and dense, the film is thin, and the film weight is 3.7g / m 2 ; Copper sulfat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com