A GaP @ C composite material, a preparation method thereof and an application in a lithium battery negative electrode

A composite material and xylene technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of unsatisfactory material cycle performance, inability to adapt to large-scale production, and poor electrochemical performance of electrodes, etc., to achieve excellent electrical performance Chemical properties and cycle stability performance, enhanced electrochemical efficiency, high density and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

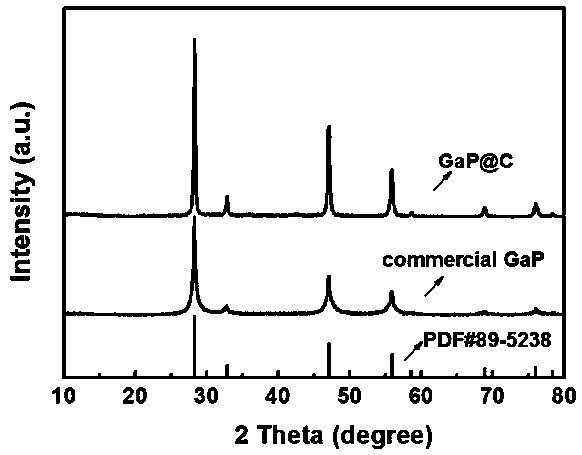

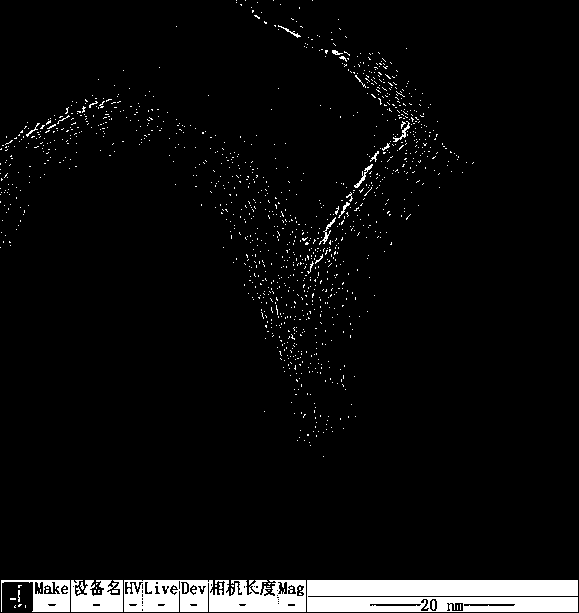

[0019] A method for preparing a GaP@C composite material, comprising the following steps: using a planetary ball mill to grind gallium phosphide GaP into powder, the ball milling environment is an argon atmosphere, the mill speed is 300 rpm (rev / min), and the ball milling time is For 2 hours, put 0.1g GaP powder in a tube furnace, heat it to 900°C, and heat it for 1 hour in an argon atmosphere carrying xylene (the mass concentration of xylene is 0.1mg / mL), and carry two The argon flow rate of toluene was 10 mL / min. The tube furnace used was purchased from Hefei Kejing Material Technology Co., Ltd., and the product model is OTF-1200X-100 open vacuum tube furnace (outer diameter 100 × inner diameter 94 × length 1000 mm).

[0020] Cyclic voltammetry test method: The cyclic voltammetry (CV) test was carried out on a CHI640D electrochemical workstation, using a three-electrode battery for testing, and the reference electrode was a circular lithium sheet with an outer diameter of 24...

Embodiment 2

[0029] A method for preparing a GaP@C composite material, comprising the following steps: using a planetary ball mill to grind gallium phosphide GaP into powder, the ball milling environment is an argon atmosphere, the mill speed is 300 rpm (rev / min), and the ball milling time is For 2 hours, put 0.1g of GaP powder in a tube furnace, heat it to 900°C, and heat it for 1 hour in an argon atmosphere carrying methane (the mass concentration of methane is 0.1mg / mL). The gas flow rate was 10 mL / min.

[0030]For the GaP@C composite material prepared in this example, when the current density is 0.5A / g, the first discharge capacity of GaP@C is 1269.1mAh / g, the first charge capacity is 1081.2mAh / g, and the first Coulombic efficiency is 85.1%. From the second cycle, the Coulombic efficiency rises to over 95%. After 100 cycles, GaP@C can only release a specific capacity of 533.7mAh / g, which is attributed to the composite material formed by the small molecule gas carbon source and the two ...

Embodiment 3

[0032] A method for preparing a GaP@C composite material, comprising the following steps: using a planetary ball mill to grind gallium phosphide GaP into powder, the ball milling environment is an argon atmosphere, the mill speed is 300 rpm (rev / min), and the ball milling time is For 2 hours, put 0.1g GaP powder and 20mg liquid xylene (through the comparative analysis of different carbon source additions, the best electrochemical performance is achieved when the xylene is 20mg) in a closed tube furnace with an argon atmosphere, and heat Heat treatment at 900°C for 1 hour in an argon atmosphere.

[0033] For the GaP@C composite material prepared in this example, when the current density is 0.5A / g, the first discharge capacity of GaP@C is 1371mAh / g, the first charge capacity is 1191.3mAh / g, and the first Coulombic efficiency is 86.9%. The Coulombic efficiency rose to over 97% at the beginning of the second cycle. After 100 cycles, GaP@C could only release a specific capacity of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com