A preparation method of a high-performance polyolefin composite battery separator and a lithium sulfur battery

A polyolefin separator and composite battery technology, applied in secondary batteries, battery pack parts, circuits, etc., can solve the problem of difficulty in ensuring battery volume energy density and mass energy density, the overall performance of the separator is not ideal, and tert-butyl lithium is easy to use. It is suitable for large-scale industrial production, alleviates the puncture ability of lithium dendrites, and improves cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

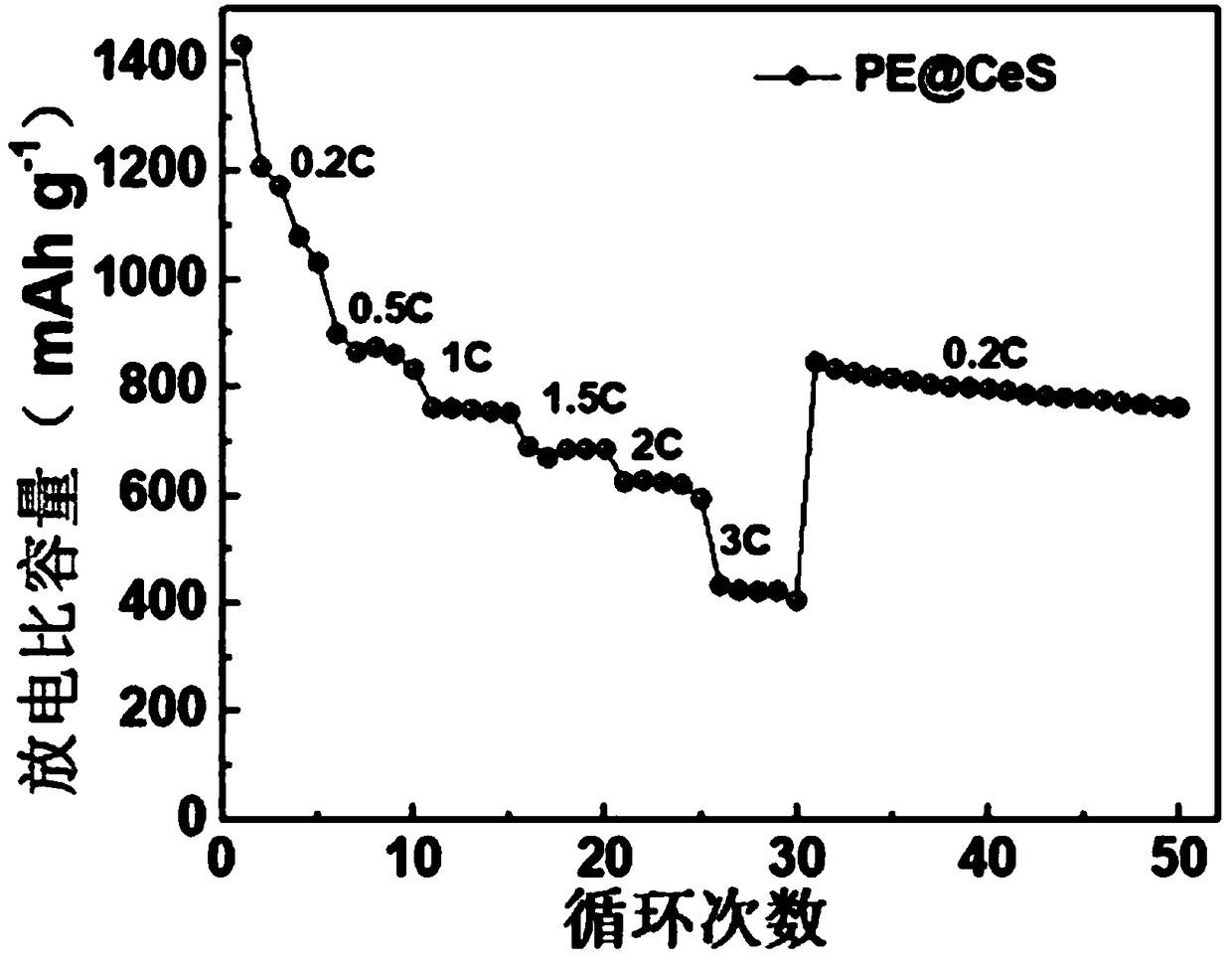

Embodiment 1

[0034] The preparation process of this embodiment is as follows:

[0035] (1) Cutting: Cut the polyolefin separator into discs with a diameter of 19 mm;

[0036] (2) Oxidation: immerse 5 polyolefin diaphragms prepared in step (1) into 100 ml of 98% concentrated nitric acid, stir for 3 hours, pre-oxidize the surface of the diaphragm, and prepare a dense active on the surface of the diaphragm. site;

[0037] (3) Mixed solvent: mix ethanol and deionized water to form a mixed solvent, and the volume ratio of ethanol to deionized water is 1:1;

[0038] (4) Prepare transition metal salt solution: dissolve 0.5 g of Ce(SO4)2 in 100 ml of the mixed solvent prepared in step (3), stir for 10 minutes to completely dissolve;

[0039] (5) Composite: immerse the diaphragm treated in step (2) into the transition metal salt solution prepared in step (4), then add 30 ml of hydrogen sulfuric acid solution with a concentration of 0.1 mole / liter dropwise, and then put the solution at room temper...

Embodiment 2

[0042] The differences between this embodiment and Embodiment 1 are:

[0043] Stirring in step (2) for 3.5 hours to pre-oxidize the surface of the diaphragm;

[0044] In step (4), dissolve 1.2 grams of FeSO4 7H2O in 100 ml of the mixed solvent prepared in step (3), stir for 10 minutes to completely dissolve

[0045] In step (5), immerse the diaphragm treated in step (2) into the transition metal salt solution prepared in step (4), then add 20 ml of hydrogen sulfuric acid solution with a concentration of 0.1 mole / liter dropwise, and then put the solution in Stir at room temperature for 2.5 hours;

[0046] In step (6), a polypropylene separator modified with ferrous sulfide nanoparticles is obtained, and the separator is applied to a lithium-sulfur battery.

[0047] All the other are the same as embodiment one.

Embodiment 3

[0049] The differences between this embodiment and Embodiment 1 are:

[0050]In step (2), immerse 5 polyolefin diaphragms prepared in step (1) into 100 ml of a mixed solution mixed with hydrogen peroxide and potassium peroxodisulfate at a volume ratio of 1:1, stir for 3.5 hours, and conduct Pre-oxidation, wherein the hydrogen peroxide is an aqueous hydrogen peroxide solution with a mass percentage of hydrogen peroxide of 15%, and the concentration of the potassium peroxodisulfate solution is 0.025 mole / liter;

[0051] In step (4), 0.9 g of MnSO4·H2O was dissolved in 100 ml of the mixed solvent prepared in step (3), and stirred for 10 minutes to completely dissolve;

[0052] In step (5), immerse the diaphragm treated in step (2) into the transition metal salt solution prepared in step (4), then add 30 ml of hydrogen sulfuric acid solution with a concentration of 0.1 mole / liter dropwise, and then put the solution in Stir at room temperature for 2.5 hours;

[0053] In step (6),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com