Treatment method of jarosite slag, ternary precursor, battery-grade iron phosphate and lithium-ion battery

The technology of a jarosite slag and a treatment method is applied in the field of jarosite slag treatment, can solve the problems of ineffective utilization, complicated process flow and high production cost, and achieves low production cost, simple process flow and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

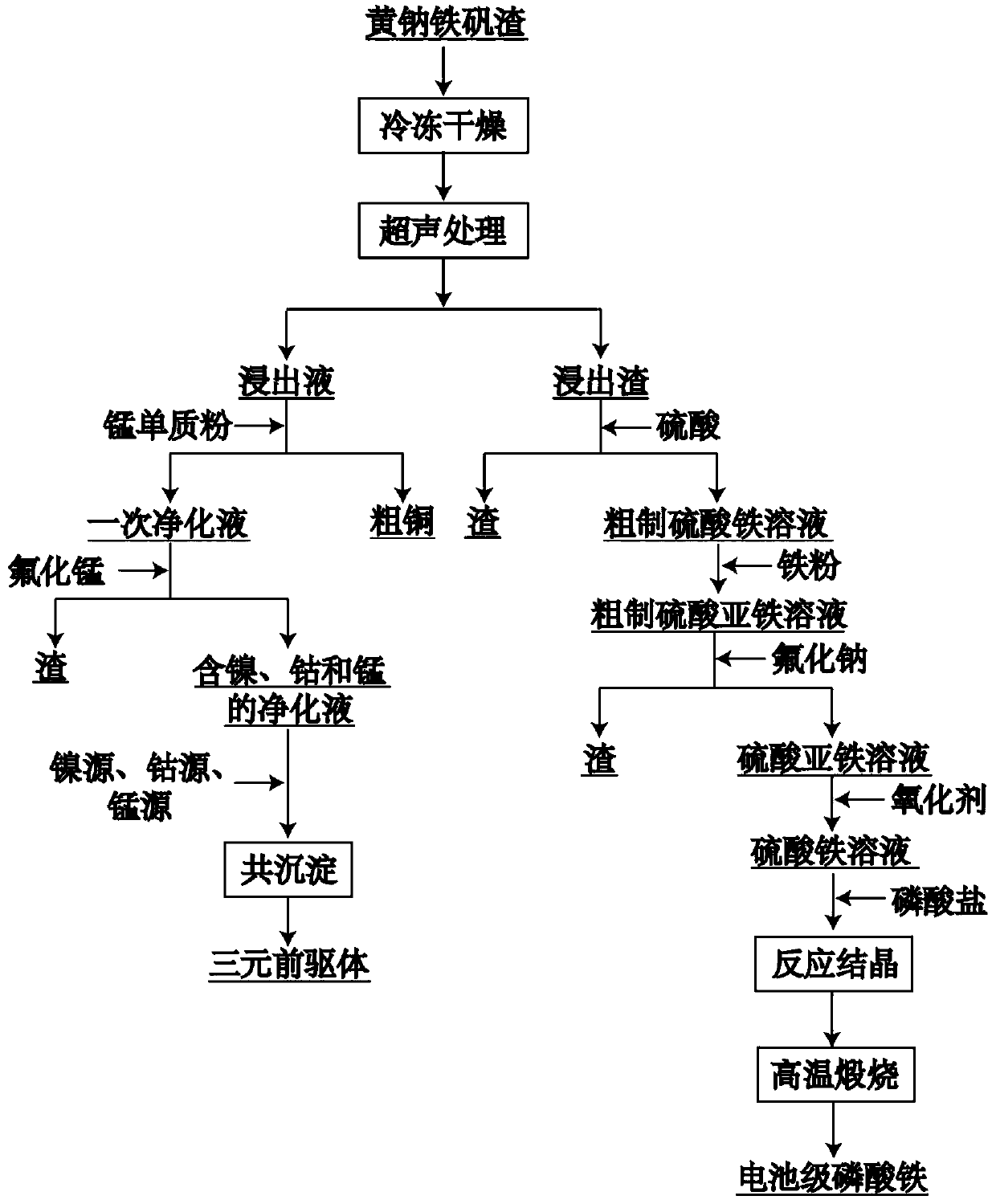

Method used

Image

Examples

preparation example Construction

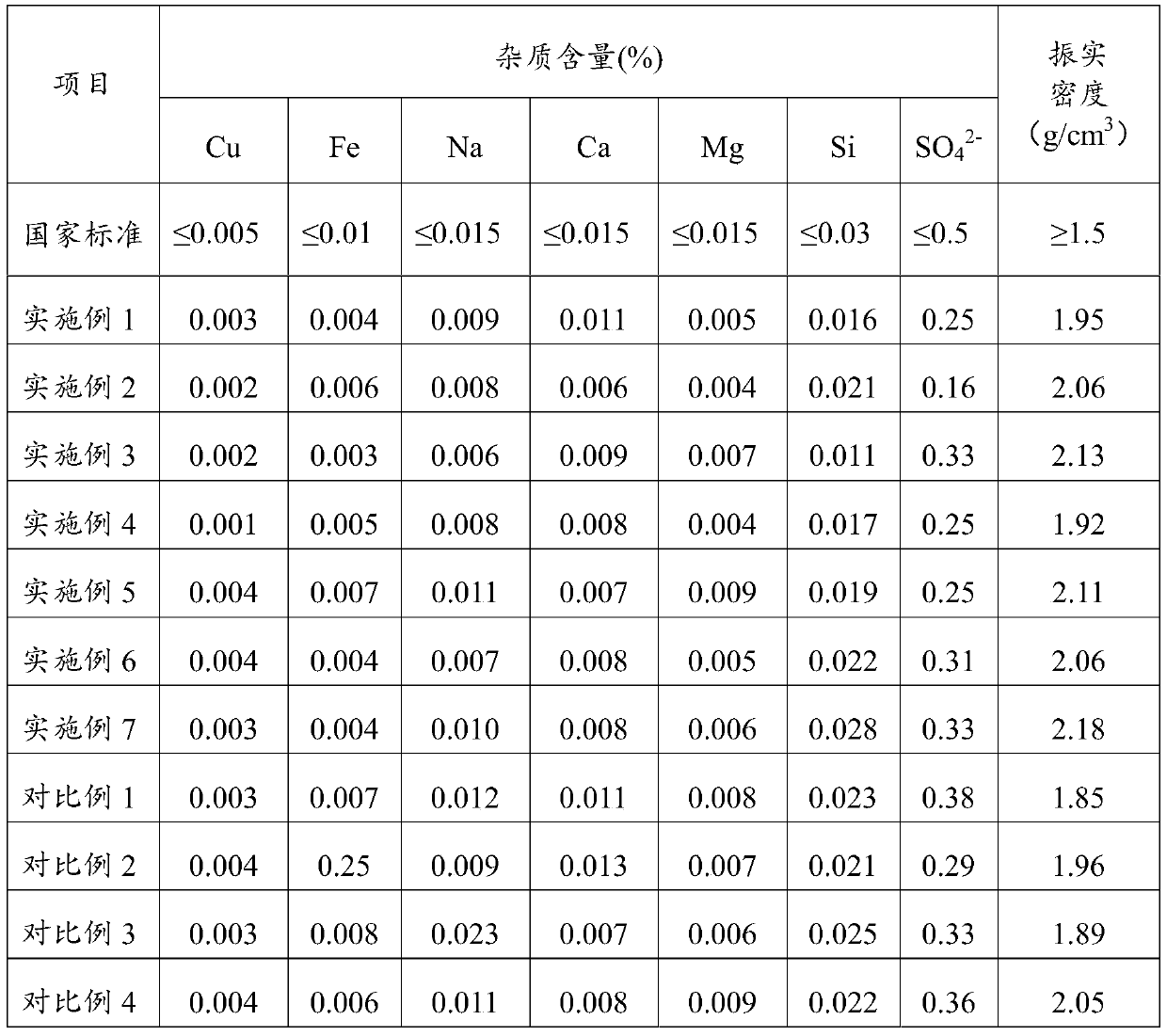

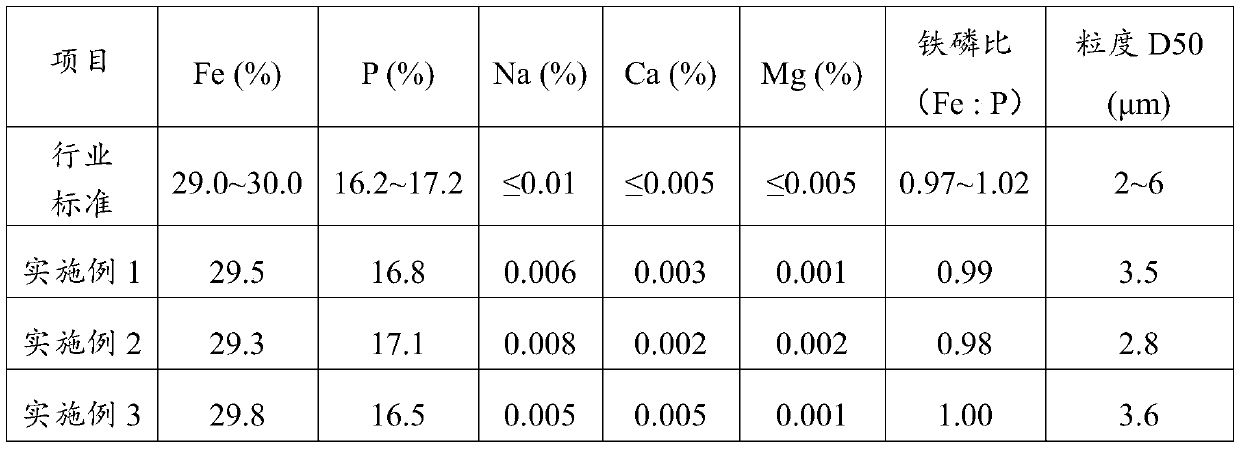

[0114] There are many methods for preparing battery-grade iron phosphate, and the direct reaction of phosphate and iron sulfate to produce iron phosphate is a common method. However, the impurity content in the ferric sulfate solution prepared by the treatment method of jarosite slag is relatively low, so it can be used as a raw material for preparing battery-grade ferric phosphate.

[0115] The ferric sulfate solution that adopts the processing method of jarosite slag to make is used as the reaction raw material of ferric phosphate, and the iron in the jarosite slag is effectively utilized, and simultaneously because other metal ion content is very low in the ferric sulfate solution, so not Can adversely affect the production of battery-grade iron phosphate.

[0116] Similar to the treatment method of the leachate, the leach residue also needs to be purified and removed. As an optional embodiment of the present invention, the leaching residue is leached by sulfuric acid, and...

Embodiment approach

[0123] As an optional embodiment of the present invention, the fluoride includes sodium fluoride or potassium fluoride, preferably sodium fluoride.

[0124] The relationship between the amount of fluoride added and the calcium ion in the crude ferrous sulfate solution follows the stoichiometric ratio. In order to fully remove calcium ions in the crude ferrous sulfate solution, the amount of fluoride added can be slightly higher than the theoretical amount of calcium ions. As an optional embodiment of the present invention, the amount of fluoride added is 1.2 to 1.35 times the theoretical amount of calcium ions in the crude ferrous sulfate solution; a typical but non-limiting amount of added fluoride is crude ferrous sulfate The multiple of the theoretical dosage of calcium ions in the solution is, for example, 1.2 times, 1.25 times, 1.3 times or 1.35 times.

[0125] As an optional embodiment of the present invention, the fluoride is sodium fluoride, and the pH of the solution...

Embodiment 1

[0154] The present embodiment provides a kind of processing method of jarosite slag, comprises the following steps:

[0155] (a) Mix jarosite slag and water at a mass ratio of 1:0.4 to make a paste, freeze and freeze rapidly at -15°C, then dry under a pressure of 5 Pa, and then use 20mm, 10mm, 5mm and 2mm ceramic balls are used as the ball milling medium, each diameter of the ball accounts for 1 / 4, and the dried jarosite slag is ball milled, and the pulverized jarosite slag particles are less than 75 μm;

[0156] Mix the pulverized jarosite slag and water at a mass ratio of 1:4 to make slurry, ultrasonically treat it and feed compressed air at the same time, the flow rate of compressed air is 1m 3 / h, the ultrasonic time is 0.8h, after the ultrasonic is finished, the leaching solution and leaching residue are obtained;

[0157] (b) leach solution treatment: add 1.1 times of manganese elemental powder of copper molar content to leach solution, replace and remove copper and obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com