Fast chemical reduction gold plating solution and application method thereof

A gold plating solution and fast technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of limiting the deposition rate and deposition thickness, affecting the solderability of the gold layer, and its stability is questionable. The effect of increasing the deposition rate of gold plating, improving surface properties, and improving various properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

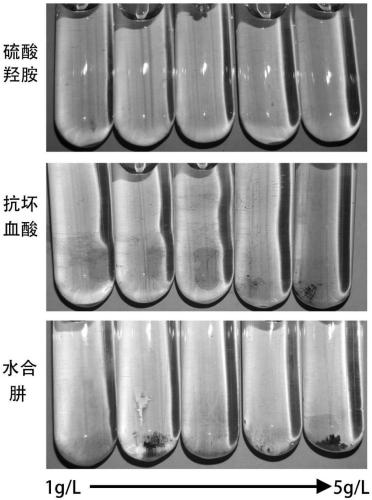

Examples

preparation example

[0030] Obtain a Ni-Pd-Au layer on the printed circuit substrate at one time, and the specific steps are as follows:

[0031]Alkaline cleaning (50°C, 5min) → water washing (distilled water, room temperature, 2min) → acid etching cleaning agent (50°C, 5min) → hot water washing (distilled water, 45°C, 2min) → water washing (distilled water, room temperature, 2min) → micro Etching (sodium persulfate 50g / L, sulfuric acid 40ml / L, normal temperature, 3min) → pickling (sulfuric acid 100ml / L) → water washing (distilled water, normal temperature, 2min) → activation (activated palladium solution, normal temperature, 2min) → water washing ( Distilled water, normal temperature, 2min)→nickel plating (80~84℃, 20min)→water washing (distilled water, normal temperature, 2min)→palladium plating (50℃, 20min)→water washing (distilled water, normal temperature, 2min)→gold plating (pH=6.3 -6.8, 86°C, 20min) → washing (distilled water, room temperature, 2min) → drying.

Embodiment 1-6

[0034] The components of the gold plating solution of Examples 1-6 are shown in Table 1.

[0035] Table 1 embodiment 1-6 gold plating solution composition

[0036]

Embodiment 7

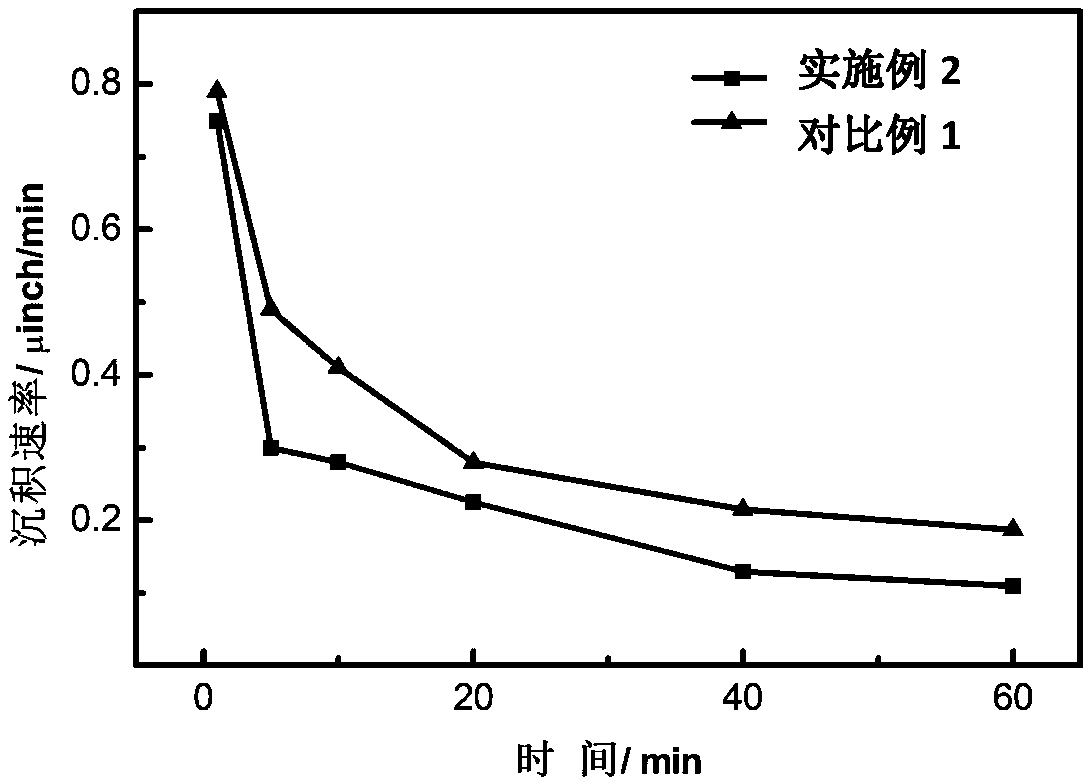

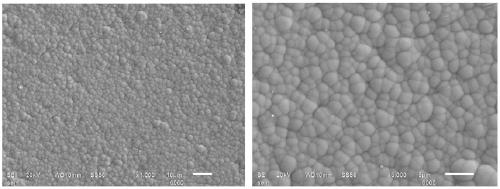

[0042] Use an XRF thickness gauge to measure the thickness of the plating layer; the brightness of the appearance of the gold layer can be obtained through a magnifying glass and visual inspection, and the bonding force can be measured by tape method. The brightness and bonding force are divided into 5 levels from 1 to 5, and the bonding force and brightness The more excellent the series is, the higher the number is; the period of the plating solution is judged by cyclic plating (the substrate is plated with gold for a cyclic experiment, and in the case of a plating solution with a gold concentration of 0.2g / L, 0.2g / L of gold is separated to The amount of plating on the substrate becomes 1MTO); the uniformity of the coating is evaluated by scanning electron microscopy; the corrosion resistance is measured by electrochemical polarization, and the porosity is calculated. The test results of Examples 1-6 are shown in Table 3, and the test results of Comparative Examples 1-10 are s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com