A kind of high bonding strength aluminum oxide resistance to hydrogen permeation and corrosion resistance insulation layer and its preparation method and application

A technology of bonding strength and corrosion resistance, which is applied in the field of hydrogen-resistant materials, can solve problems such as poor bonding strength and mismatching thermal expansion coefficients, and achieve high bonding strength, high compactness, and self-repairing bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

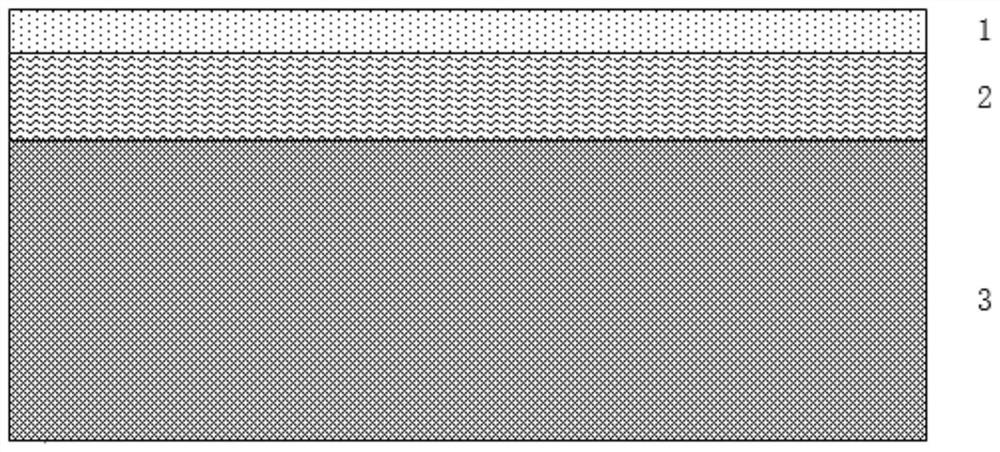

Image

Examples

Embodiment 1

[0023] Preparation of α-Al for Fusion Reactor Cladding Structure Material with a Thickness of 100 μm 2 o 3 Hydrogen permeation resistance corrosion resistant insulating layer:

[0024] (1) Polish the surface of the cladding structure material to a roughness of 1 μm;

[0025] (2) Spray a layer of iron-chromium-aluminum layer on the surface of fusion reactor cladding structure material at room temperature by cold spraying method; the specific process parameters are: spraying temperature is 100°C, spraying powder is FeCr 20 Al 5 Mixed metal powder, the thickness of FeCrAl layer is about 100μm;

[0026] (3) Preparation of α-Al by thermal oxidation of alloy coated samples by in-situ thermal oxidation method 2 o 3 Hydrogen-resistant permeable layer; the specific process parameters are: oxidation temperature is 800°C, oxidation atmosphere is atmospheric oxidation, oxidation time is 8h, α-Al 2 o 3 The thickness of the hydrogen barrier coating is about 120nm.

[0027] (4) Final...

Embodiment 2

[0030] Preparation of α-Al for Fusion Reactor Cladding Structure Material with a Thickness of 10 μm 2 o 3 Hydrogen permeation resistance corrosion resistant insulating layer:

[0031] (1) Polish the surface of the cladding structure material to a roughness of 0.5 μm;

[0032] (2) A layer of FeCrAl layer is sputtered with three targets by magnetron sputtering; the specific process parameters are: the vacuum degree of the sputtering vacuum chamber is controlled at 10 -4 Pa range, and select iron, chromium and aluminum targets with a purity of 99.99%, and obtain 10μm thick FeCr by controlling the sputtering time of each target 15 Al 7 Mixed metal layer.

[0033] (3) Preparation of α-Al by thermal oxidation of alloy coated samples by in-situ thermal oxidation method 2 o 3 Hydrogen-resistant permeable layer; the specific process parameters are: oxidation temperature is 800°C, oxidation atmosphere is atmospheric oxidation, oxidation time is 8h, α-Al 2 o 3 The thickness of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com