Wear-resistant welding wire and preparation method thereof

A welding wire and wire drawing technology, applied in welding equipment, welding medium, manufacturing tools, etc., can solve the problems of low C content, high cost of precious metals, low wear resistance, etc., achieve uniform internal and external density, ensure the quality of welding wire, and improve wear resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

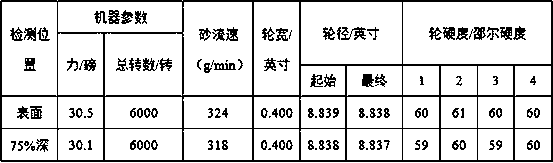

Image

Examples

Embodiment 1

[0039] A wear-resistant welding wire, prepared by the following method:

[0040]Make vanadium carbide, molybdenum carbide, niobium carbide, nickel carbide, nickel boride, ferrochromium, ferrosilicon, ferromanganese, iron powder and graphite into powder, pass through a 30-mesh sieve, and use a metal powder moisture detector to detect the moisture content≤1 %, weighed and proportioned according to the following weight percentages: chromium: 40.00%; carbon: 8.00%; manganese: 0.50%; silicon: 0.40%; boron: 2.50%; vanadium: 0.10%; %; molybdenum: 0.10%; the balance is iron; fully stir and mix the weighed powder for 100 minutes to obtain mixture A; after blowing the surface of the steel strip with nitrogen at a wind speed of 10m / s, fill the mixture A on the steel strip ; The steel belt filled with mixture A is detachably installed on the vibrating rod, the vibrating rod is connected to the vibrating motor, and the mixture A in the steel belt is vibrated and mixed to obtain the mixture...

Embodiment 2

[0042] A wear-resistant welding wire, prepared by the following method:

[0043] Make vanadium carbide, molybdenum carbide, niobium carbide, nickel carbide, nickel boride, ferrochromium, ferrosilicon, ferromanganese, iron powder and graphite into powder, pass through a 50-mesh sieve, and use a metal powder moisture detector to detect the moisture content≤1 %, weighed and proportioned according to the following weight percentage: chromium: 10.00%; carbon: 3.00%; manganese: 4.00%; silicon: 3.50%; boron: 2.50%; vanadium: 2.00%; nickel: 0.05%; %; molybdenum: 0.50%; the balance is iron; fully stir and mix the weighed powder for 120 minutes to obtain mixture A; after blowing the surface of the steel strip with nitrogen at a wind speed of 12m / s, fill the mixture A on the steel strip ; Subsequent operation steps are consistent with embodiment 1.

Embodiment 3

[0045] A wear-resistant welding wire, prepared by the following method:

[0046] Make vanadium carbide, molybdenum carbide, niobium carbide, nickel carbide, nickel boride, ferrochromium, ferrosilicon, ferromanganese, iron powder and graphite into powder, pass through a 40-mesh sieve, and use a metal powder moisture detector to detect the moisture content≤1 %, weighed and proportioned according to the following weight percentage: chromium: 17.00%; carbon: 3.50%; manganese: 1.00%; silicon: 3.00%; boron: 0.40%; vanadium: 0.80%; nickel: 0.50%; %; molybdenum: 0.10%; the balance is iron; fully stir and mix the weighed powder for 130 minutes to obtain mixture A; after blowing the surface of the steel strip with nitrogen at a wind speed of 15m / s, fill the mixture A on the steel strip ; Subsequent operation steps are consistent with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com