Preparation of a self-crosslinking composite solid-state electrolyte and its all-solid-state lithium-ion battery

A solid electrolyte and lithium-ion battery technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, solid electrolytes, etc. It can solve problems affecting the electrochemical performance of the electrolyte, the deviation of the mechanical properties of the electrolyte, and the complexity of the preparation process, and achieve ionic conductivity. Good, small product shrinkage, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

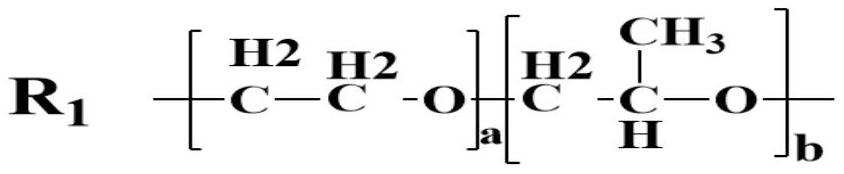

[0034] Polypropylene oxide (number-average molecular weight=12000) of 3g terminal silane-terminated polyether, 3g Li 7 La 3 ZrO 12 , 4ml acetonitrile and 4ml tetraethylene glycol dimethyl ether are evenly mixed; add 3g lithium hexafluorophosphate (LiPF 6 ) mixed evenly; the uniformly stirred mixed solution was scraped onto a polytetrafluoroethylene mold, heated at 60°C for 8 hours in a blast drying oven, and transferred to a vacuum oven at 80°C for curing for 4 hours to form a film.

Embodiment 2

[0036] Mix 1.5g polypropylene oxide (number average molecular weight=12000) of silane-terminated polyether, 1g acid-treated PEO, 2ml propylene carbonate and 30ml tetrahydrofuran; add 0.8g lithium hexafluorophosphate (LiPF 6 ) mixed evenly; the uniformly stirred mixed solution was scraped onto a polytetrafluoroethylene mold, heated at 60°C for 8 hours in a blast drying oven, and transferred to a vacuum oven at 80°C for curing for 4 hours to form a film.

Embodiment 3

[0038] 2.2g polypropylene oxide (number average molecular weight=12000) of capping polyether, SiO after 2.8g alkaline treatment 2 Mix evenly with 4ml triethylene glycol dimethyl ether; add 1.4g lithium bistrifluoromethanesulfonylimide (LiTFSI) and mix evenly; scrape the evenly stirred mixed solution on the polytetrafluoroethylene mold, and dry it in the blast Heat at 60°C for 8 hours in the oven, transfer to a vacuum drying oven at 80°C for 4 hours to form a film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrochemical stability window | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com