Vertical graphene/niobium-titanium-oxygen/sulfur-carbon composite material with three-dimensional porous array structure and preparation method and application of vertical graphene/niobium-titanium-oxygen/sulfur-carbon composite material

A sulfur-carbon composite material, three-dimensional porous technology, applied in nanotechnology, structural parts, electrical components, etc. for materials and surface science, can solve the problem of lack of fast electron transmission channels, etc., and achieve superior cycle stability and high magnification Performance, the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] (1) Preparation method of vertical graphene (VG): By plasma enhanced chemical vapor deposition (PECVD), VG arrays are deposited on carbon cloth in an orderly manner (microwave frequency is 2.45 GHz and microwave power is 2 kW). Firstly, arrange the carbon in the cavity and make the gas pressure reach 10mTorr; secondly, after raising the temperature of the cavity to 400°C, hydrogen plasma is generated in the cavity. 2 Produced in the air stream, while introducing methane. During the whole reaction process, the ratio of hydrogen to methane was 3:2, and the reaction time was kept at 2 h. Finally, it was cooled to room temperature 25 °C, and the VG sample preparation was completed.

[0038] (2) VG / TiNb 2 o 7 The preparation method: the VG substrate was dried in an oven for 12 hours and weighed. After weighing, the vertical graphene (VG) was used as the growth substrate, and the isopropyl titanate (C 12 h 28 o 4 Ti) and niobium pentachloride (NbCl 5 ) as a precursor fo...

Embodiment 1

[0041] The VG substrate was dried in a vacuum oven. Using isopropyl titanate (C 12 h 28 o 4 Ti) and niobium pentachloride (NbCl 5 ) was used as a precursor for solvothermal reaction at 200°C for 6h, and then cooled with the furnace. The obtained sample was washed several times with deionized water and absolute ethanol, dried, and calcined at 700 °C for 2 h under an argon protective atmosphere with a heating rate of 5 °C / min to obtain VG / TiNb 2 o 7 Film samples. Take VG / TiNb 2 o 7 For the core, the EDOT and LiClO 4 A galvanostatic anodic deposition was carried out in acetonitrile solution. After about 10s, the PEDOT polymer will be uniformly deposited on the VG / TiNb 2 o 7 array, forming a core-shell structure, and then calcined in a tube furnace at 700 °C for 2 h (Ar atmosphere) to obtain VG / TiNb 2 o 7 @S-C Three-dimensional porous array.

Embodiment 2

[0043] The VG substrate was dried in a vacuum oven. Using isopropyl titanate (C 12 h 28 o 4 Ti) and niobium pentachloride (NbCl 5 ) was used as a precursor for solvothermal reaction at 200°C for 6h, and then cooled with the furnace. The obtained sample was washed several times with deionized water and absolute ethanol, dried, and calcined at 700 °C for 2 h under an argon protective atmosphere with a heating rate of 5 °C / min to obtain VG / TiNb 2 o 7 Film samples. Take VG / TiNb 2 o 7 For the core, the EDOT and LiClO 4 A galvanostatic anodic deposition was carried out in acetonitrile solution. After about 20s,

[0044] PEDOT polymer will be deposited uniformly on VG / TiNb 2 o 7 array, forming a core-shell structure, and then calcined in a tube furnace at 700 °C for 2 h (Ar atmosphere) to obtain VG / TiNb 2 o 7 @S-C Three-dimensional porous array.

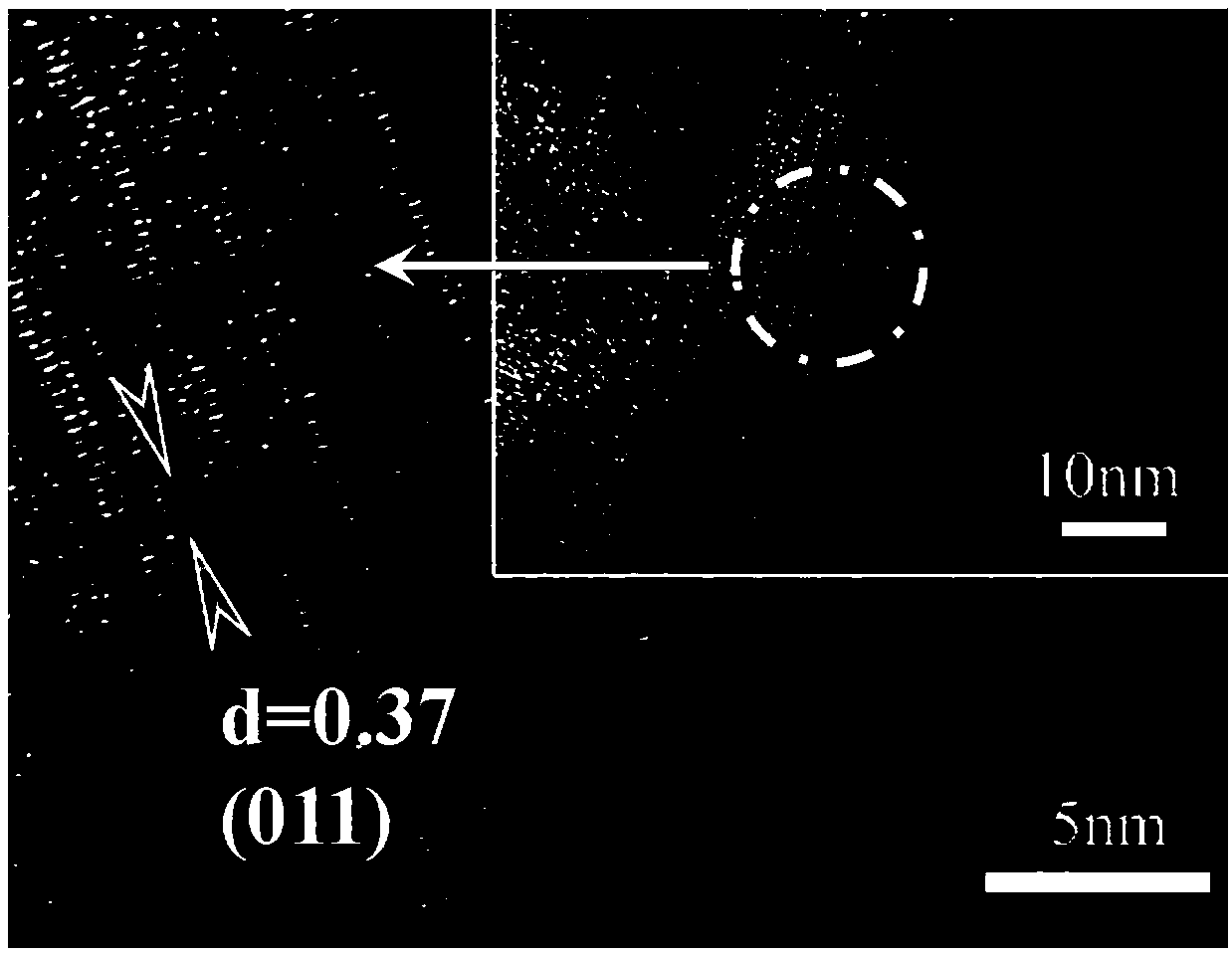

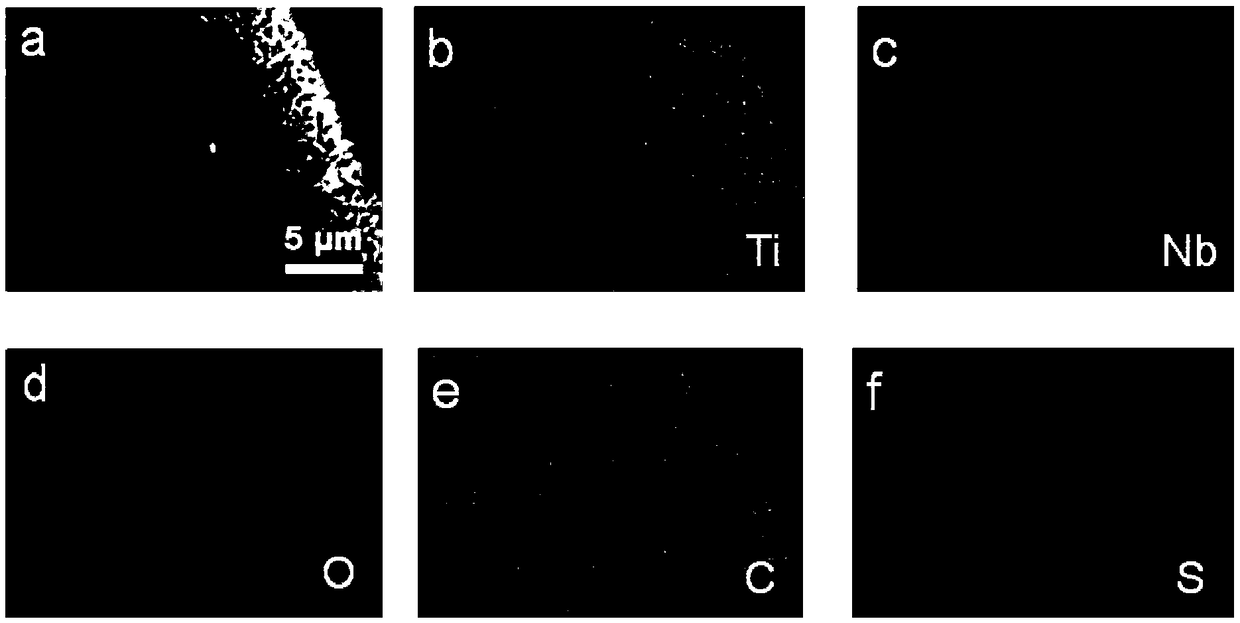

[0045] The VG / TiNb that makes in embodiment 2 2 o 7 The scanning electron microscope image of the array is shown in figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com