Micro driver of piezoelectric fiber composite material for pipeline and fabrication method of micro driver

A piezoelectric fiber and composite material technology, applied in piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve problems such as the influence of driving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

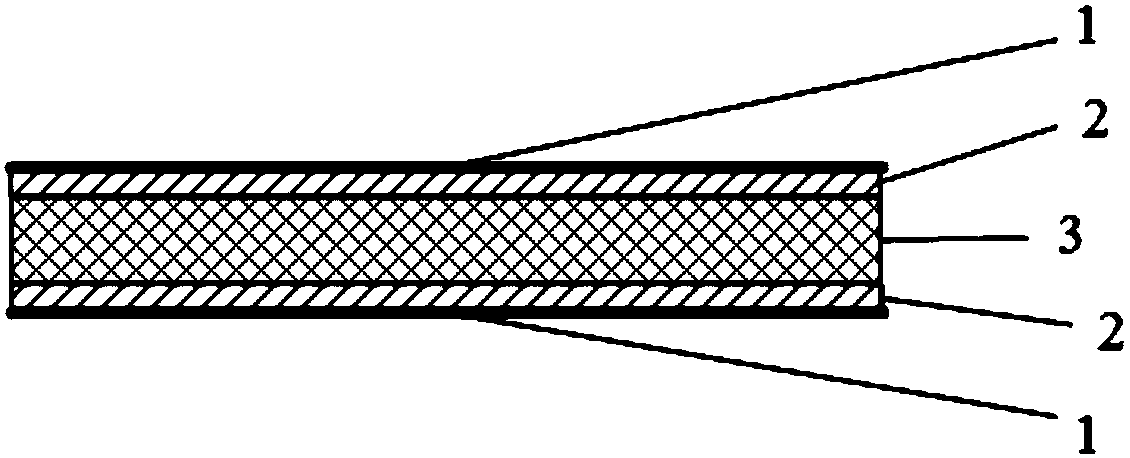

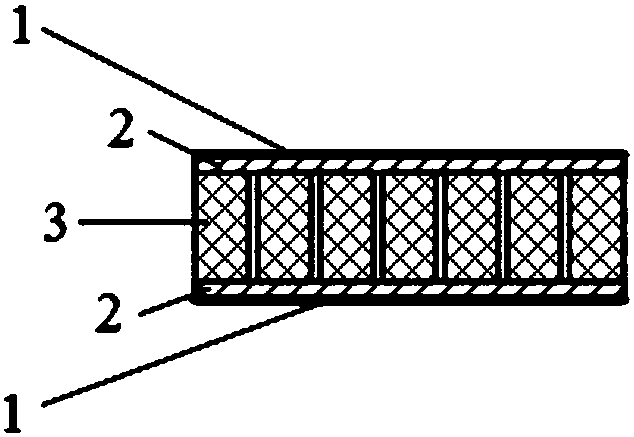

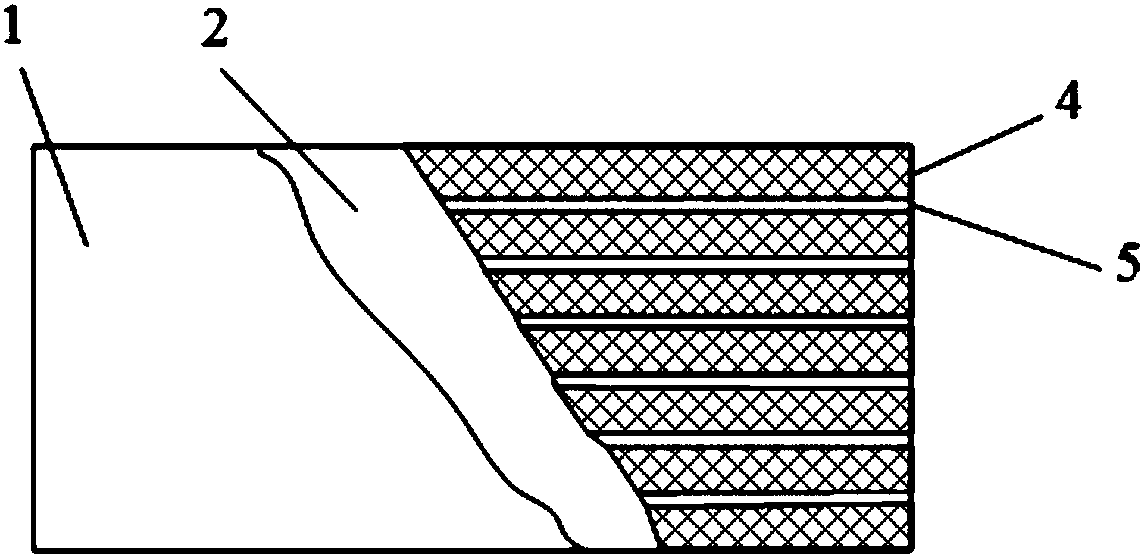

[0031] A piezoelectric fiber composite micro-driver for pipelines, the structure of which is as follows Figure 1-3 As shown, it includes: piezoelectric fiber layer 3, which is composed of laminated piezoelectric ceramic fibers 4, and two adjacent ceramic fibers 4 are bonded by pressure-sensitive adhesive 5, wherein the piezoelectric ceramic fibers are made of 1 mm thick pressure-sensitive adhesive. The electric ceramic sheet is cut into 1*0.5mm rectangular cross-section macrofiber. The pressure-sensitive adhesive 5 used is a thermoplastic pressure-sensitive adhesive. What is used in this embodiment is ethylene-vinyl acetate polymer resin (EVA), with an elastic modulus of 80 MPa, an ultimate strain rate of 200%, and a softening temperature of 90°C. It has good elasticity, flexibility, waterproof and corrosion resistance. Correspondingly, by utilizing the softening property of EVA at 90°C, the complex thermal curing process after casting is abandoned during the preparation, an...

Embodiment 2

[0039] A piezoelectric fiber composite micro-driver for pipelines, comprising laminated piezoelectric ceramic fibers, a piezoelectric fiber layer bonded by pressure-sensitive adhesive between two adjacent ceramic fibers, coated on the piezoelectric fiber layer The epoxy structural adhesive film layer containing dicyandiamide curing agent on the upper and lower surfaces; the interdigitated electrode layer attached to the outer surface of the adhesive film layer. The pressure-sensitive adhesive is a thermoplastic pressure-sensitive adhesive, and polyethylene terephthalate (PET) hot-melt adhesive is used in this embodiment, the strain rate at break is >200%, and the peel strength at 180°C is >4N cm. Softening temperature>80℃. The interdigitated electrode layer is made of polyimide film, and the inner side of the polyimide film is engraved with copper interdigitated electrodes.

[0040] The preparation method of the piezoelectric fiber composite material micro-driver for the pipe...

Embodiment 3

[0046]A piezoelectric fiber composite micro-driver for pipelines, which consists of laminated piezoelectric ceramic fibers, a piezoelectric fiber layer bonded by pressure-sensitive adhesive between two adjacent ceramic fibers, coated on the piezoelectric fiber layer The epoxy structural adhesive film layer containing dicyandiamide curing agent on the upper and lower surfaces; the interdigital electrode layer attached to the outer surface of the adhesive film layer. The pressure-sensitive adhesive is a thermoplastic pressure-sensitive adhesive, and polyamide (PA) hot-melt adhesive is used in this embodiment, with tensile strain rate at break>200%, peel strength at 180°C>4N·cm, and softening temperature at 110°C. The interdigitated electrode layer is made of polyimide film, and the inner side of the polyimide film is engraved with copper interdigitated electrodes. Its preparation method is with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com