Comprehensive utilization method of waste FCCU catalyst

A technology of catalyst and mixed liquid, which is applied in the field of comprehensive utilization of waste FCCU catalysts, can solve the problems of long process route, dripping, complicated operation, etc., and achieve the effects of low operation complexity, avoiding the risk of poisoning, and short process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

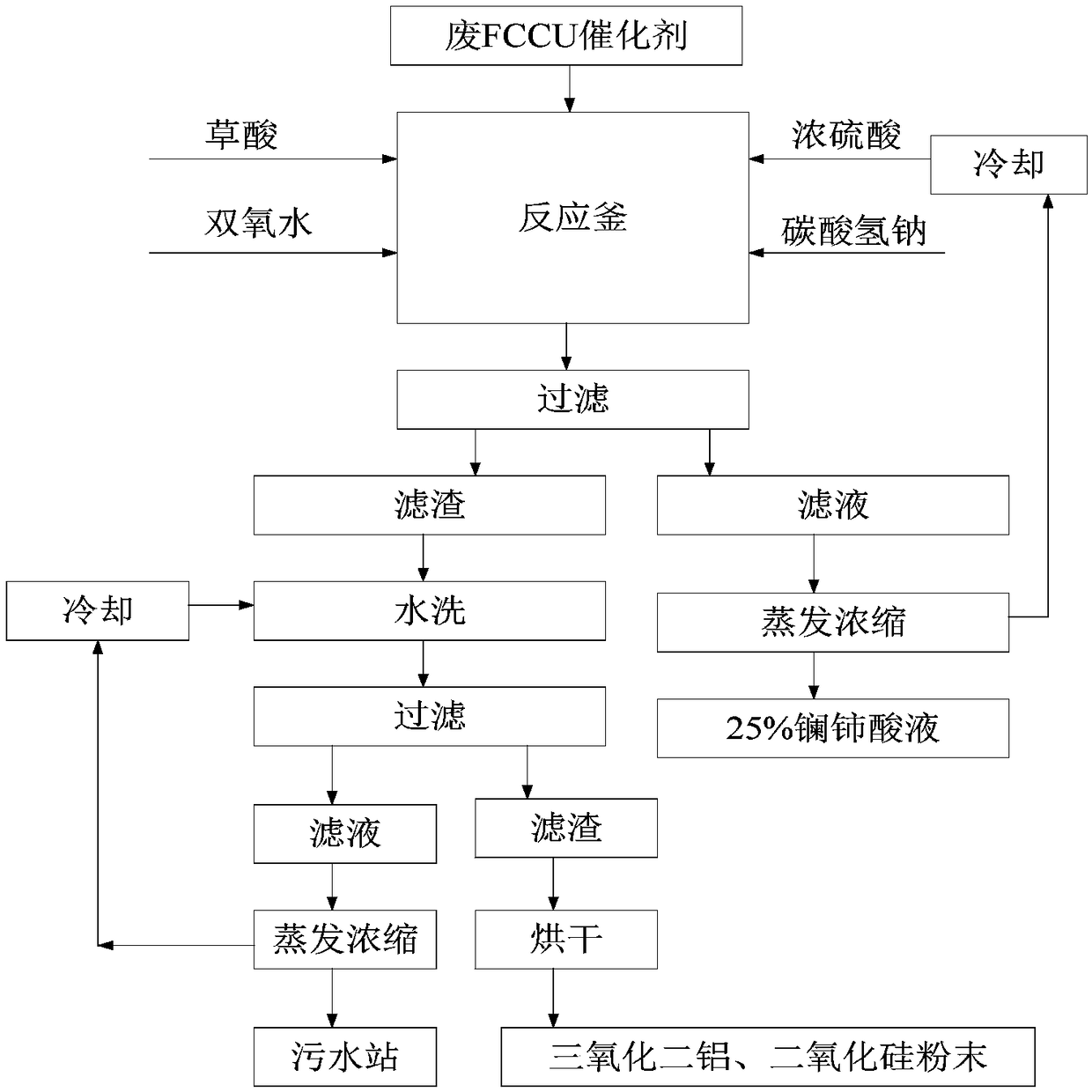

Method used

Image

Examples

Embodiment 1

[0026] Mix 500ml of concentrated sulfuric acid and 700g of FCCU catalyst in a reaction kettle, heat to 80°C and stir for 2 hours, then cool down to 60°C, add 15ml of hydrogen peroxide and 10ml of oxalic acid at the same time, mix and stir for 30 minutes, add 20g of sodium bicarbonate and stir for 30 minutes, stir Keep the reaction temperature at 95°C during the process, filter, evaporate the filtrate at 10KPa and 165°C to evaporate about 85% of concentrated sulfuric acid, the concentration of concentrated sulfuric acid obtained at this time is ≮76%, and the content of lanthanum and cerium rare earth elements in the concentrated filtrate is ≥17%. Fe, Cu, S, Pb, As total≯3.5%. The filter residue is washed with water and then dried to obtain a mixed powder of alumina and silicon dioxide with a metal content (excluding Al) ≤ 0.5%.

Embodiment 2

[0028] Mix 500ml of concentrated sulfuric acid and 700g of FCCU catalyst in a reaction kettle, heat to 80°C and stir for 3 hours, then add 15ml of hydrogen peroxide and 10g of oxalic acid at the same time, mix and stir for 60 minutes, add 20g of sodium bicarbonate and stir for 60 minutes, keep the reaction during stirring Filter at 95°C, evaporate about 85% of concentrated sulfuric acid from the filtrate at 10KPa and 165°C, the concentration of concentrated sulfuric acid obtained at this time is ≮83%, and the content of lanthanum and cerium rare earth elements in the concentrated filtrate is ≥21%, Fe, Cu, The total of S, Pb, and As is ≯5%. The filter residue is washed with water and then dried to obtain aluminum trioxide and silicon dioxide powders with a metal content (excluding Al) ≤ 0.1%.

Embodiment 3

[0030] Mix 500ml of concentrated sulfuric acid and 700g of FCCU catalyst in a reaction kettle, heat to 120°C and stir for 2 hours, then cool down to 80°C, add 15ml of hydrogen peroxide and 10ml of oxalic acid at the same time, mix and stir for 30 minutes, add 20g of sodium bicarbonate and stir for 30 minutes, During the stirring process, keep the reaction temperature at 95°C, filter, evaporate the filtrate at 10KPa, 165°C, about 85% of concentrated sulfuric acid, the concentration of concentrated sulfuric acid obtained at this time is ≮81%, and the content of lanthanum and cerium rare earth elements in the concentrated filtrate is ≥19% , Fe, Cu, S, Pb, As total≯2%. The filter residue is washed with water and then dried to obtain alumina and silicon dioxide powders with a metal content of ≤0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com