Preparation method of low-cost high-density MgB2 super-conducting wire rod

A superconducting wire and dense technology, applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve the problems of low-density grain connectivity, etc., to solve holes and cracks, Effects of improving connectivity and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

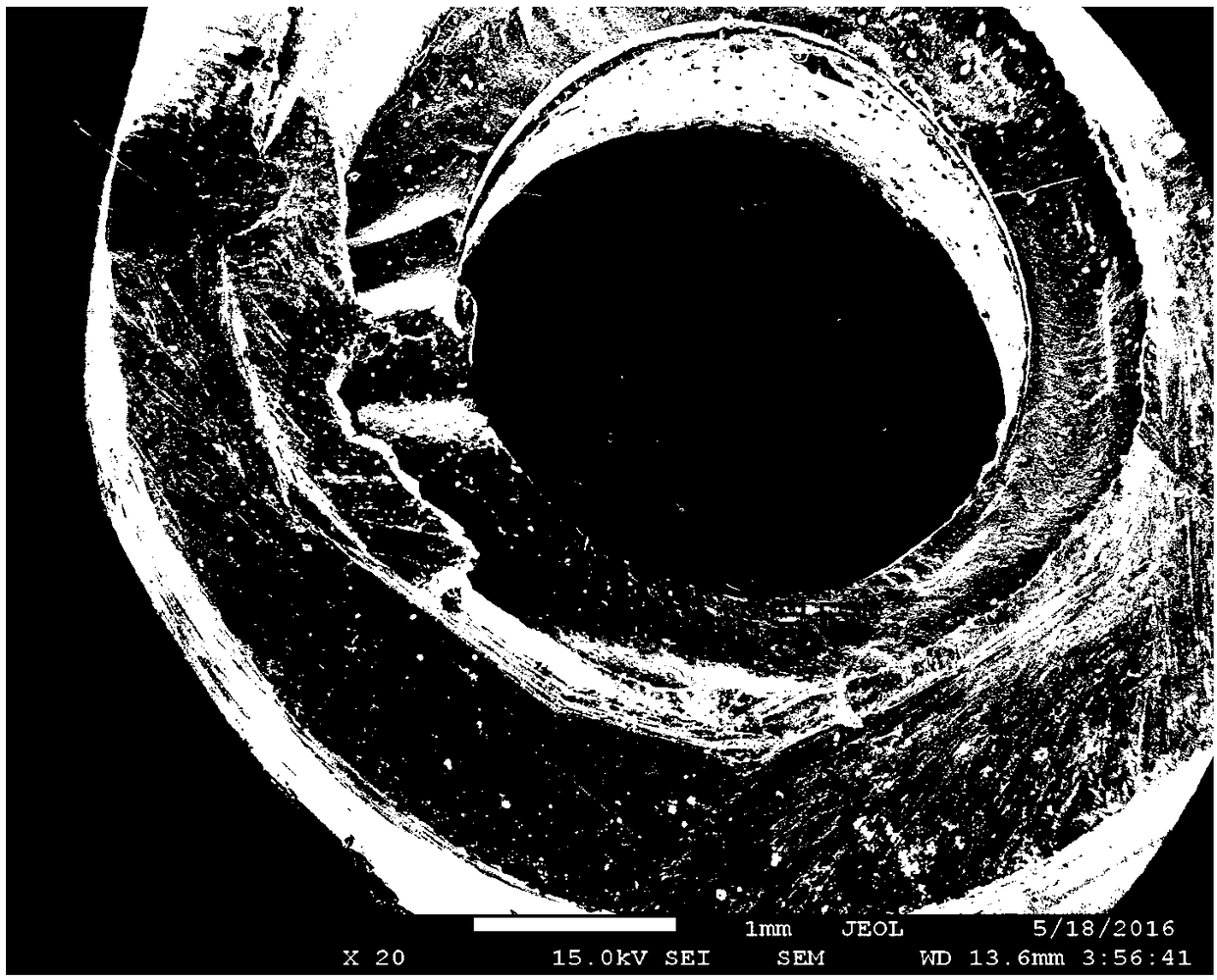

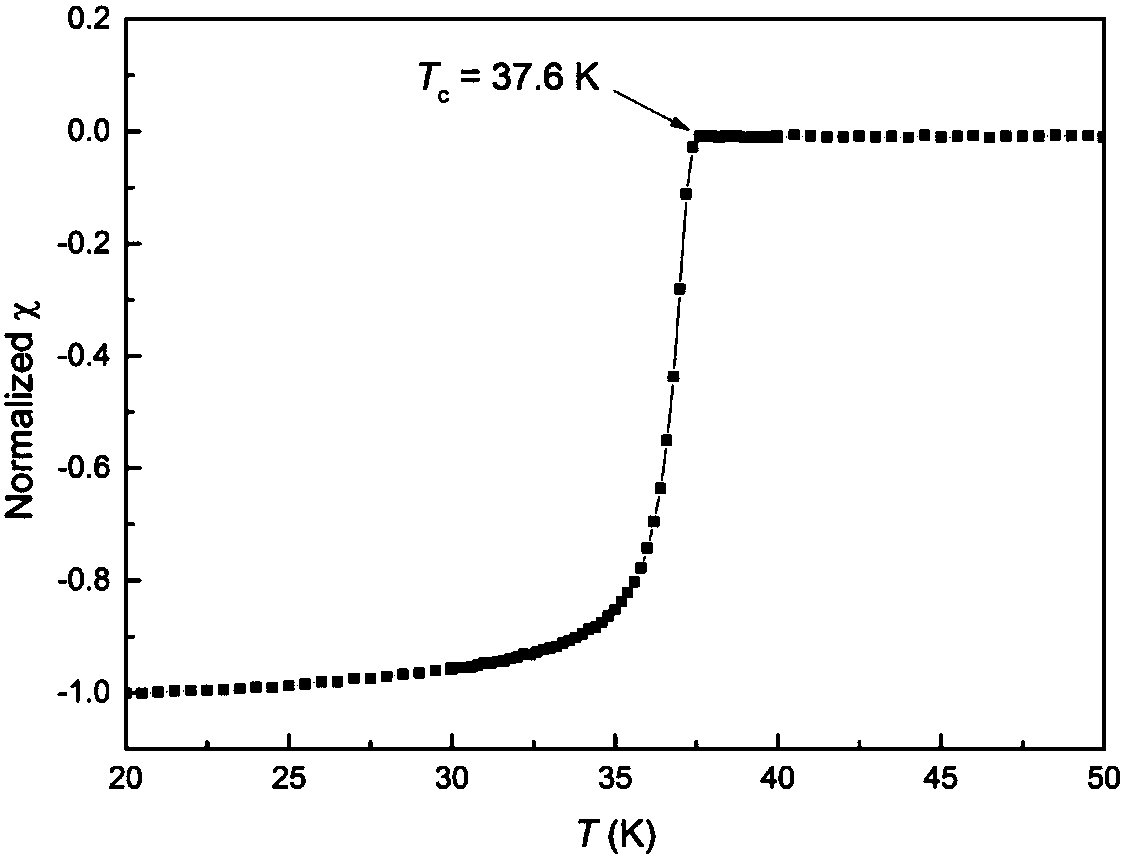

[0027] S1. Pioneer powder tube preparation: in a vacuum glove box, B powder, MgB4 powder and graphene are uniformly mixed in a molar ratio of 0.895:0.025:0.005, wherein the purity of B powder is 99%, and the average particle size is 0.5 μm;

[0028] S2. Insert a high-purity magnesium rod with a diameter of 3mm into the center of a stainless steel tube with a diameter of 6mm and fix it. Put the uniformly mixed precursor powder in step S1 around the magnesium rod of the stainless steel tube. The filling amount is calculated according to the ratio of Mg:B=1:2 , and seal both ends of the stainless steel tube, wherein the outer diameter of the stainless steel tube is 8mm, the inner diameter is 6mm, and the purity of magnesium in the high-purity magnesium rod is 99.95%;

[0029] S3, swaging processing: take out the above-mentioned installed stainless steel pipe from the vacuum glove box, and swage it on a swaging machine to form a filament with a diameter of 3.75mm;

[0030] S4. Hea...

Embodiment 2

[0034] S1. Pioneer powder tube preparation: put B powder and MgB in a vacuum glove box 4The powder and graphene are uniformly mixed according to the molar ratio of 0.798:0.05:0.002, wherein the purity of powder B is 99%, and the average particle size is 0.5 μm;

[0035] S2. Insert a high-purity magnesium rod with a diameter of 3 mm into the center of a stainless steel tube with a diameter of 6 mm and fix it. Put the uniformly mixed precursor powder in step S1 around the magnesium rod of the stainless steel tube. The filling amount is calculated according to the ratio of Mg:B=1:2 , and seal both ends of the stainless steel tube, wherein the outer diameter of the stainless steel tube is 8mm, the inner diameter is 6mm, and the purity of magnesium in the high-purity magnesium rod is 99.95%;

[0036] S3. Swivel processing: take out the above-mentioned installed stainless steel pipe from the vacuum glove box, and swage it on a swaging machine to form a filament with a diameter of 1....

Embodiment 3

[0041] S1. Pioneer powder tube preparation: put B powder and MgB in a vacuum glove box 4 The powder and graphene are uniformly mixed according to the molar ratio of 0.69:0.075:0.01, wherein the purity of powder B is 99%, and the average particle size is 0.5 μm;

[0042] S2. Then insert a high-purity magnesium rod with a diameter of 3 mm into the center of a stainless steel tube with a diameter of 6 mm and fix it. Put the uniformly mixed precursor powder in step S1 around the magnesium rod of the stainless steel tube. The filling amount is in the ratio of Mg:B=1:2 Calculate and seal both ends of the stainless steel pipe, wherein the outer diameter of the stainless steel pipe is 8mm, the inner diameter is 6mm, and the purity of magnesium in the high-purity magnesium rod is 99.95%;

[0043] S3, swaging processing: take out the above-mentioned installed stainless steel pipe from the vacuum glove box, and swage it on a swaging machine to form a filament with a diameter of 2.65 mm; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com