Preparation for composite carbon based nano zero-valent iron micro electrolysis material and method for treating antimony-contained wastewater

A nano-zero valent iron, micro-electrolysis technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Strict requirements, etc., to achieve the effect of reducing the production of iron sludge, beneficial to adsorption, and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Example 1 : The preparation method of composite carbon-based nano zero-valent iron micro-electrolytic material of the present invention

[0072] The specific preparation method of the composite carbon-based nano zero-valent iron micro-electrolytic material provided by the present invention can be divided into the following steps:

[0073] First of all, the raw materials are prepared. First, 100g of raw coal and 278g of iron ore with a content of 60% are firstly ground by a ball mill for no less than 30 minutes, passing through 400 meshes, mixing the ground raw coal and iron ore powder, adding 67g of basic copper carbonate and 67g of Bentonite, mixed evenly, placed in a ball mill and ground for no less than 30 minutes, passed through a sieve below 400 mesh for later use.

[0074] Secondly, add an appropriate amount of water to the prepared raw materials to make mud. It is advisable that the mud is agglomerated and not sticky, and it is sealed and aged for more than 2 h...

Embodiment 2

[0077] Example 2 : Structural characterization of composite carbon-based nano zero-valent iron micro-electrolytic materials of the present invention

[0078] This embodiment is to characterize the structure of the composite carbon-based nano-zero-valent iron micro-electrolytic material, as follows:

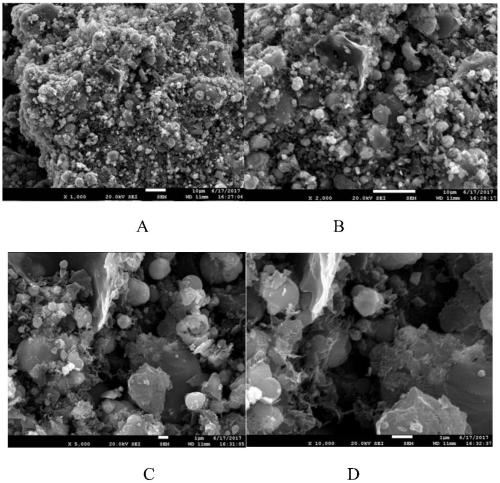

[0079] 1. SEM photos

[0080] The particle size and morphology of composite carbon-based nano-zero-valent iron micro-electrolytic materials were analyzed using a Hitachi S-2400 field emission scanning electron microscope in Japan.

[0081] image 3 It is a scanning electron microscope picture of composite carbon-based nano-zero-valent iron micro-electrolytic material particles magnified 1000 times (A), 3000 times (B), 5000 times (C) and 10000 times (D). It can be seen from the picture that the carbon-based Regular spherical and cubic small particles with uniform particle size are evenly distributed on the material, which are copper element and iron element respectively, and th...

Embodiment 3

[0094] Example 3 : The application method of composite carbon-based nano zero-valent iron micro-electrolytic material of the present invention

[0095] The application method of the composite carbon-based nano zero-valent iron micro-electrolytic material provided by the present invention can be divided into the following steps:

[0096]First, the antimony-containing wastewater is introduced into the flocculation sedimentation tank (or filtration system), and polyferric sulfate (or polyaluminum ferric sulfate) and sodium metasilicate coagulant are added to flocculate the suspended particles, and the clear water is introduced into the intermediate pool.

[0097] Secondly, pump the pretreated antimony-containing waste water into the micro-electrolysis reactor. The micro-electrolysis reactor adopts the flow mode of water inflow from the bottom and water outflow from the top. The packing density of the micro-electrolysis filler is 75%, and the thickness of the reaction bed is 2m~ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com