Preparation method and application of modified zeolite permeable reactive wall filling carrying zero-valent iron powder

A technology of osmotic reaction wall and modified zeolite, which is applied in the field of preparation of osmotic reaction wall filler, can solve the problems of engineering application limitation, difficult repair effect, difficult reaction process control, etc., and achieve the effect of solving the loss of iron powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

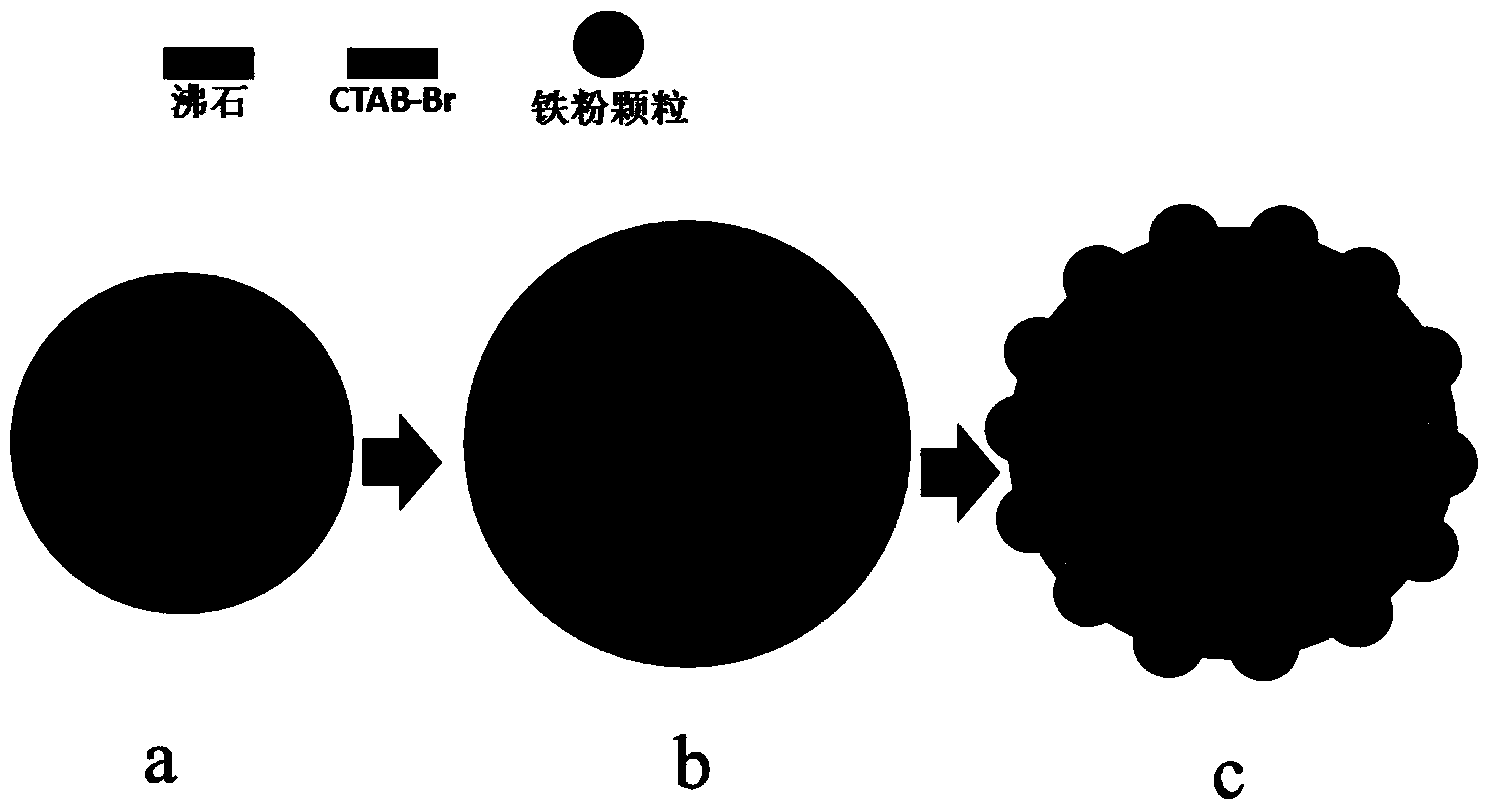

[0029] The present invention will be described in detail below through Embodiment 1 in conjunction with the accompanying drawings.

[0030] Clinoptilolite was purchased from Zhengzhou, Henan, with a bulk density of 1.6g / cm 3 . The detailed steps are as follows:

[0031] 1) The 1-2mm clinoptilolite screened out with a standard sieve was washed 5 times with distilled water, and dried at 105°C for later use.

[0032] 2) Take a sufficient amount of the dried clinoptilolite, immerse it in 18g / L CTAB-Br solution, and modify it in a constant temperature shaker at 25°C and 150r / min for 24h. Get 1-b figure.

[0033] 3) Wash the modified clinoptilolite with distilled water 5 times, and dry at 105°C for later use.

[0034] 4) Add 36g of 200 mesh iron powder into 30mL of 15g / L sodium alginate solution, and stir well to form a mixture of iron powder and sodium alginate solution.

[0035] 5) Take 90mL (144g) of the modified zeolite dried in step 3) and put it into the mixed solution fo...

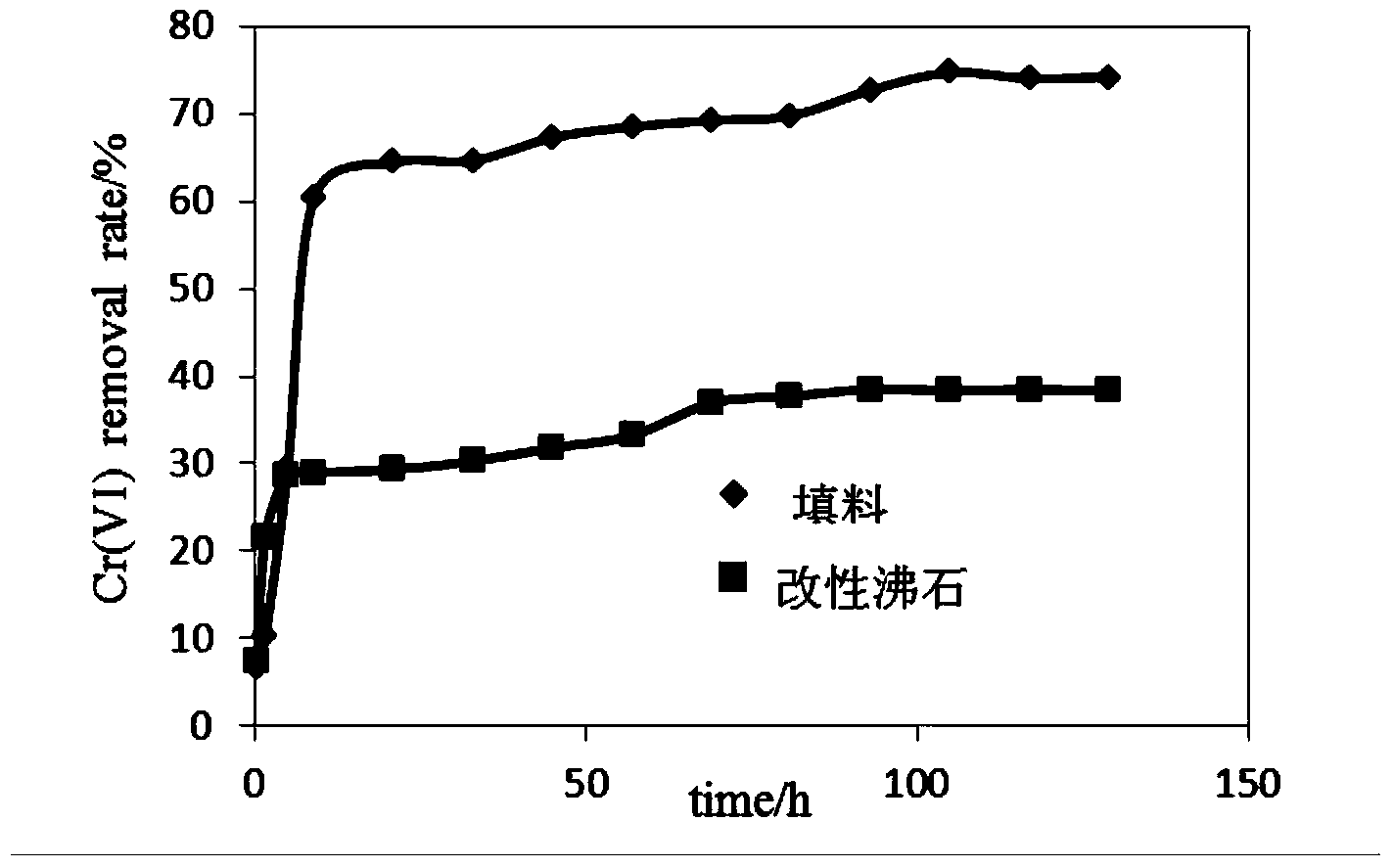

Embodiment 2

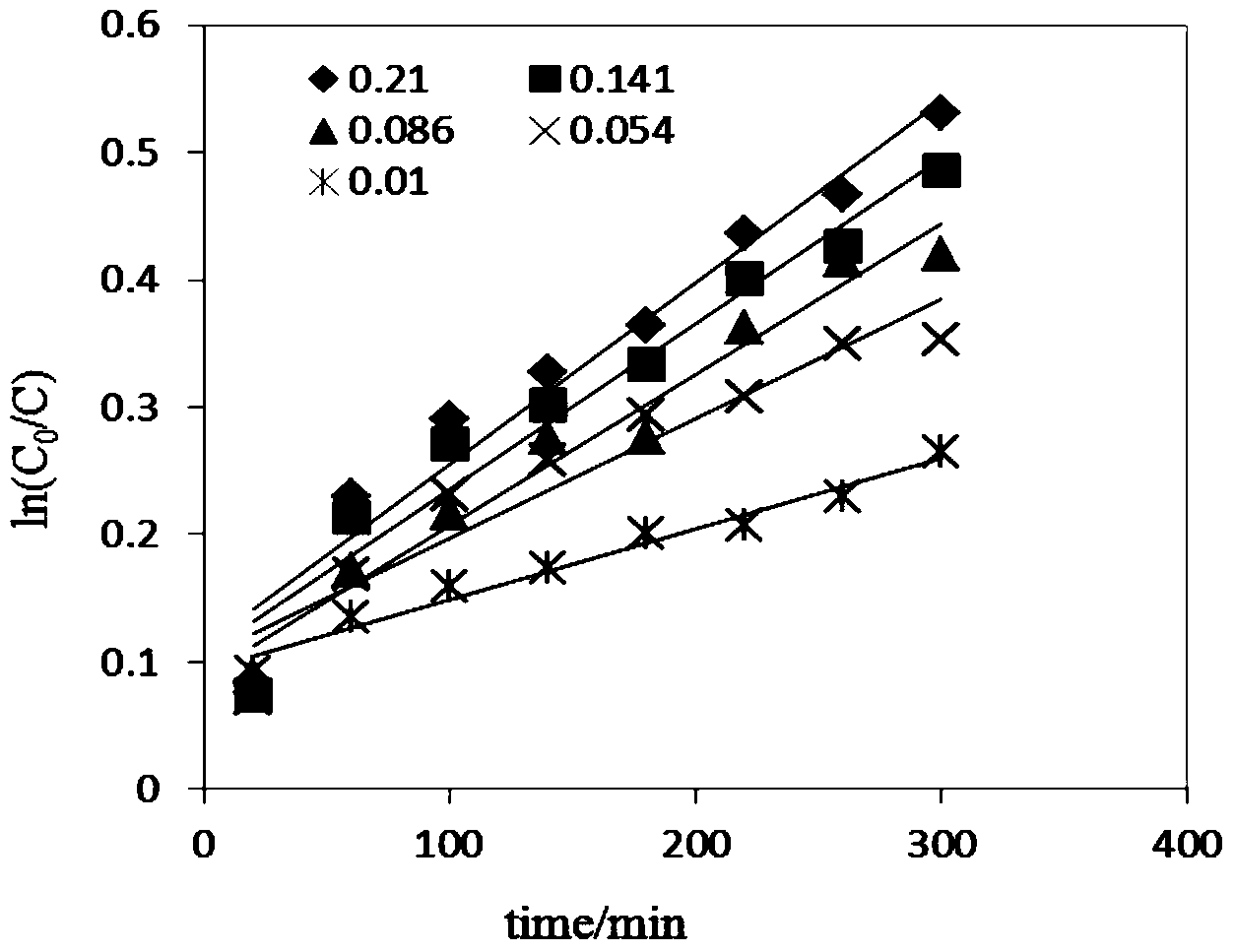

[0041] The difference from Example 1 is that the dosage of iron powder and the dosage of modified zeolite are changed. The preparation and implementation process of other required materials are the same as in Example 1. According to the initial iron powder dosage is 20% of the total mass of the initial iron powder and modified zeolite, the volume ratio of modified zeolite to sodium alginate solution is 3.5:1. The modified clinoptilolite-loaded zero-valent iron powder filler with a fixed iron powder content of 14.1% was prepared.

Embodiment 3

[0043] The difference from Example 1 is that the dosage of iron powder and the dosage of modified zeolite are changed. The preparation and implementation process of other required materials are the same as in Example 1. According to the initial iron powder dosage is 5% of the total mass of the initial iron powder and modified zeolite, the volume ratio of modified zeolite to sodium alginate solution is 3.5:1. The modified clinoptilolite-loaded zero-valent iron powder filler with the fixed iron powder content of 1.0% was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com