Corrosion-resistant neutral chrome-free coating agent and preparation method thereof

A technology of corrosion resistance and coating agent, applied in the field of chemicals, can solve the problems of large difference in corrosion resistance between silane film and phosphating film, long difference in corrosion resistance and corrosion resistance, and failure to achieve corrosion resistance. Achieve excellent physical properties and corrosion resistance, improve corrosion resistance, high corrosion resistance and the effect of salt spray time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

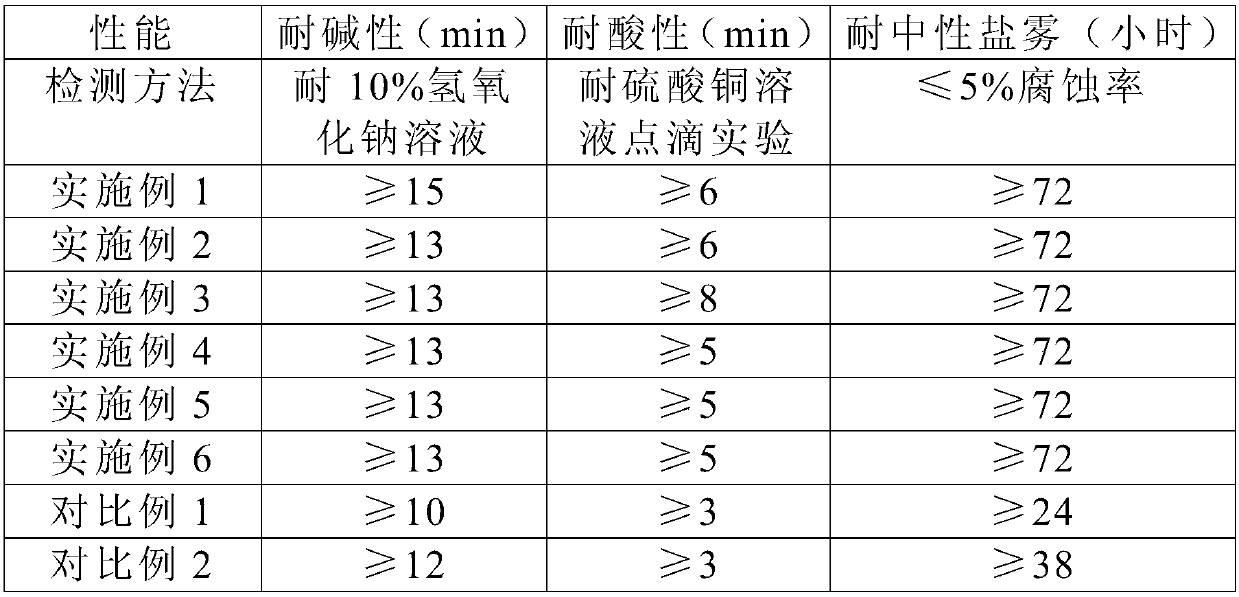

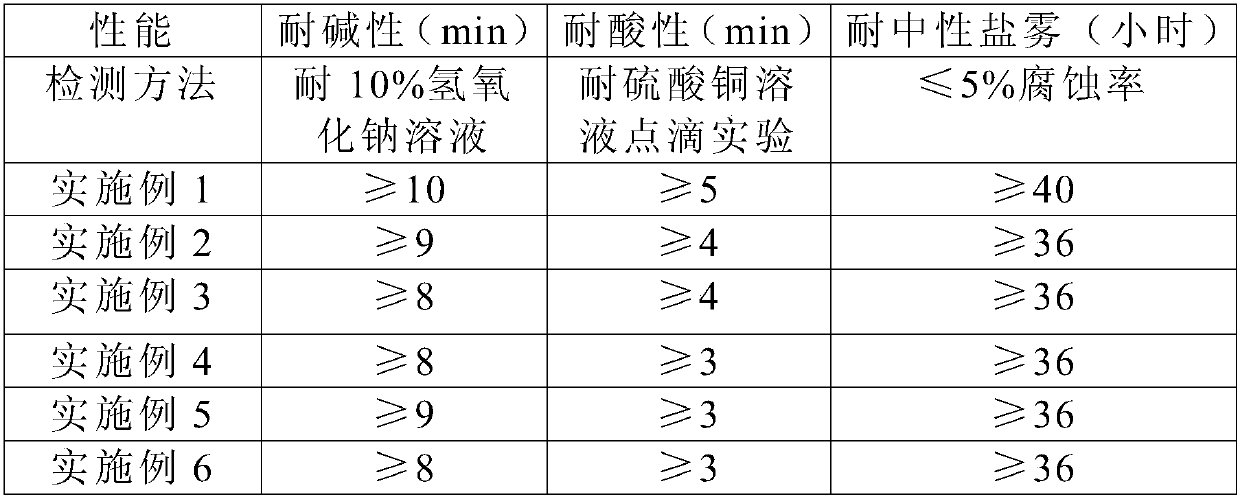

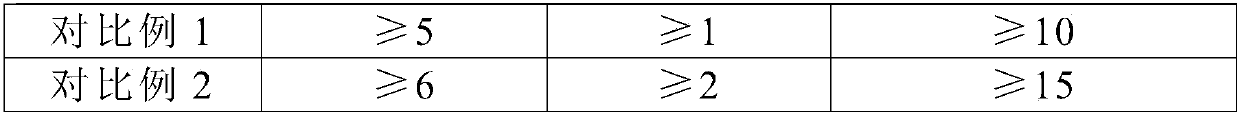

Examples

Embodiment 1

[0042] Mix 8 parts of low-viscosity hydroxypropyl methylcellulose, 2 parts of ethanol, 8 parts of 1,2-propanediol and 30 parts of water evenly and stir until dissolved, as material A;

[0043] Mix 2 parts of γ-aminopropyl triethoxysilane, 1 part of γ-glycidyl etheroxypropyl trimethoxysilane, 10 parts of nano-oxide sol and 30 parts of water, stir for 20-30 hours, as material B ;

[0044] Stir material A and material B evenly, then add 1 part of cerium sulfate and 3 parts of water, and adjust the pH value to 7 with 2 parts of pH regulator to obtain a chrome-free coating agent.

Embodiment 2

[0046] Mix 3 parts of polyacrylic acid (PAA), 3 parts of gelatin, 2 parts of methanol, 4 parts of acetone and 25 parts of water and stir until dissolved, as material A;

[0047] Mix 6 parts of vinyltrichlorosilane, 15 parts of nano-silica sol and 25 parts of water evenly, stir for 20-30 hours, and use it as material B;

[0048] Stir material A and material B evenly, then add 2 parts of titanyl sulfate, 1 part of zirconium oxychloride octahydrate and 5 parts of water, and adjust the pH value to 7 with 2 parts of pH regulator to obtain a chromium-free coating agent.

Embodiment 3

[0050] Mix 4 parts of acrylic acid / maleic acid copolymer (AA-MA), 4 parts of hydroxycellulose, 1 part of ethylene glycol monoethyl ether, 3 parts of methyl acetate and 30 parts of water and stir until dissolved, as material A ;

[0051] Mix 6 parts of γ-chloropropyl-trimethoxysilane, 8 parts of nano-titanium dioxide sol, 4 parts of nano-alumina sol and 20 parts of water, stir for 20-30 hours, and use it as material B;

[0052] Stir material A and material B evenly, then add 1 part of sodium molybdate, 1 part of sodium metasilicate pentahydrate and 10 parts of water, and adjust the pH value to 6 with 1 part of pH regulator to obtain a chromium-free coating agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com