Negative oxygen ion health care function polyester fiber and preparation method thereof

A technology of polyester fibers and negative oxygen ions, applied in the fields of fiber chemical characteristics, melt spinning, stretch spinning, etc., can solve the problems of broken ends and flying flowers, increase the difficulty of post-processing, and the difficulty of industrialization, etc., to achieve improved release The ability of negative ions, excellent moisture absorption characteristics, and the effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

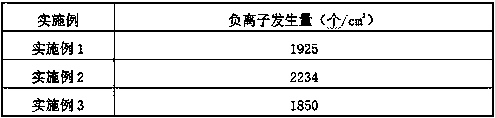

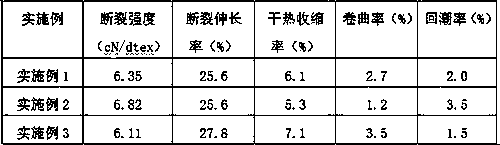

Examples

Embodiment 1

[0044] A preparation method of polyester fiber with negative oxygen ion health care function, comprising the following steps:

[0045] (1) Use a nano grinder to grind tourmaline particles into tourmaline nanopowder with a particle size of 50-100 nanometers;

[0046] (2) Mix and disperse the cellulose spinning stock solution with the tourmaline nanopowder prepared in step (1) and the denaturant JL-V to make a tourmaline-cellulose functional film: take the cellulose spinning stock solution and step (1) The prepared tourmaline nanopowder and denaturant are mixed and dispersed evenly, thinned into a liquid film, and then the liquid film is placed in an acid bath, and removed after 10s to form a cellulose film; the cellulose film is placed in 0.1mol / L hydrogen Sodium oxide solution to remove carbon disulfide to prevent safety accidents; then put the cellulose in an oven and dry it for 20 minutes at a temperature of 90°C to make an air stone-cellulose functional film; tourmaline-cel...

Embodiment 2

[0055] A preparation method of polyester fiber with negative oxygen ion health care function, comprising the following steps:

[0056] (1) Use a nano grinder to grind tourmaline particles into tourmaline nanopowder with a particle size of 50-100 nanometers;

[0057] (2) Mix and disperse the cellulose spinning stock solution with the tourmaline nanopowder prepared in step (1) and the denaturant JL-V to make a tourmaline-cellulose functional film: take the cellulose spinning stock solution and step (1) The prepared tourmaline nanopowder and denaturant are mixed and dispersed evenly, thinned into a liquid film, and then the liquid film is placed in an acid bath, and removed after 10s to form a cellulose film; the cellulose film is placed in 0.5mol / L hydrogen In the sodium oxide solution, carbon disulfide is removed to prevent safety accidents; then the cellulose is put into an oven and dried at a temperature of 110°C for 20 minutes to make an airstone-cellulose functional film; ...

Embodiment 3

[0068] A preparation method of polyester fiber with negative oxygen ion health care function, comprising the following steps:

[0069] (1) Use a nano grinder to grind tourmaline particles into tourmaline nanopowder with a particle size of 50-100 nanometers;

[0070] (2) Mix and disperse the cellulose spinning stock solution with the tourmaline nanopowder prepared in step (1) and the denaturant JL-V to make a tourmaline-cellulose functional film: take the cellulose spinning stock solution and step (1) The prepared tourmaline nanopowder and denaturant are mixed and dispersed evenly, thinned into a liquid film, and then the liquid film is placed in an acid bath, and removed after 10s to form a cellulose film; the cellulose film is placed in 0.1mol / L hydrogen Sodium oxide solution to remove carbon disulfide to prevent safety accidents; then put the cellulose in an oven and dry it for 40 minutes at a temperature of 90°C to make an air stone-cellulose functional film; tourmaline-cel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com