Flux cored wire for gas shielded arc welding

A technology of gas shielding and flux-cored welding wire, applied in arc welding equipment, welding equipment, welding media, etc., can solve the problems that it is difficult to improve the hygroscopic properties of flux, and the hygroscopic properties have not been studied, so as to achieve good welding operability and improve hygroscopic properties , excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the form for implementing this indication is demonstrated in detail. In addition, this indication is not limited to each embodiment shown below.

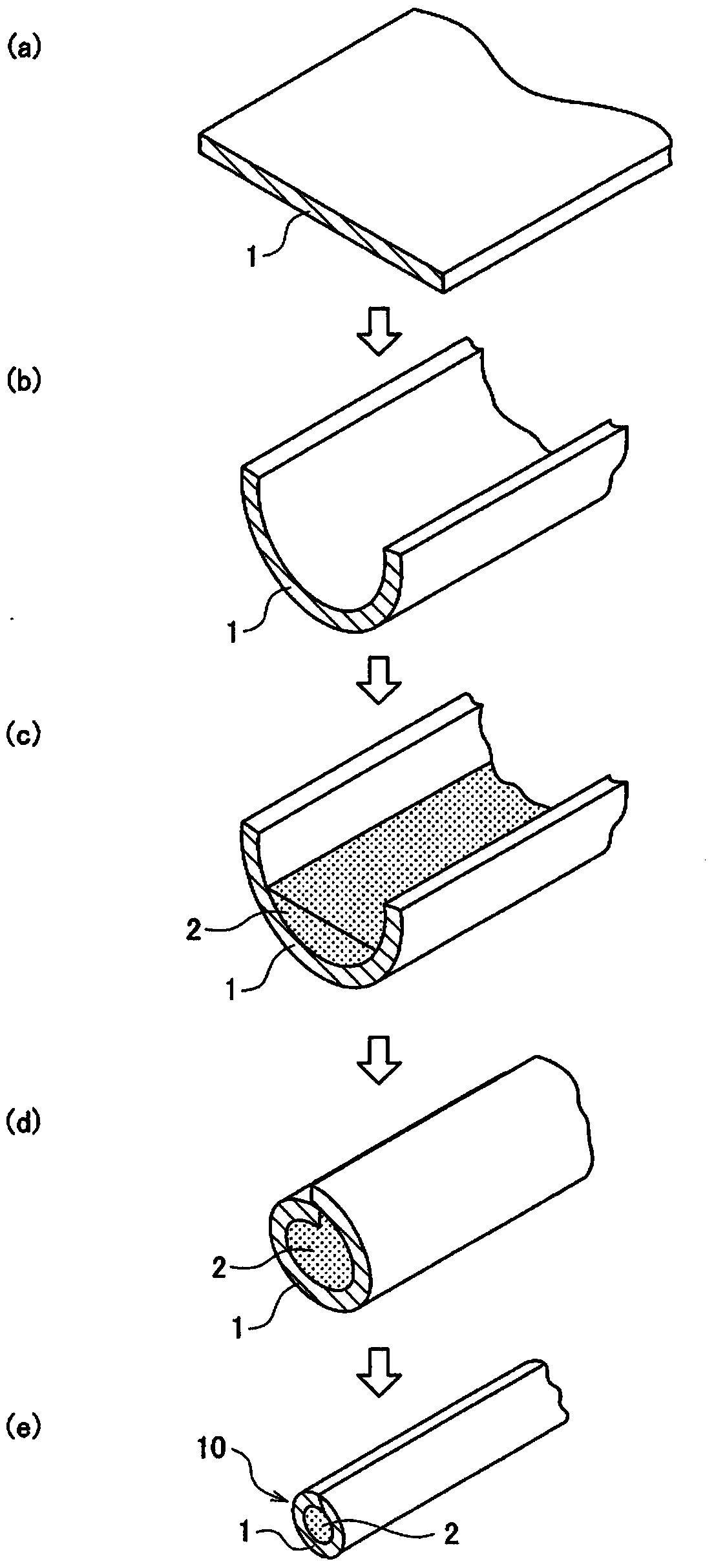

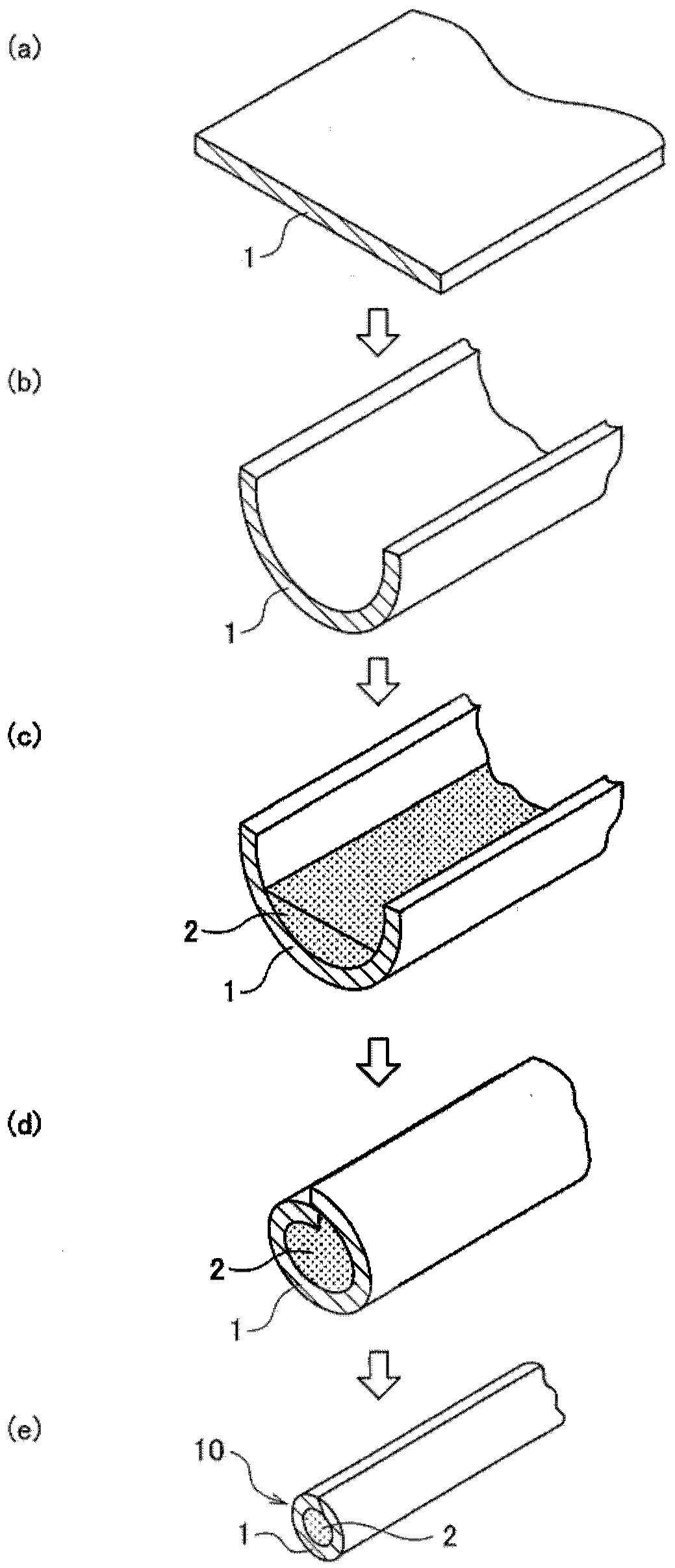

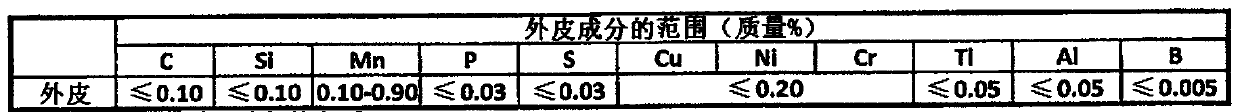

[0021] The flux-cored welding wire of the present embodiment has a steel sheath filled with flux, and its outer diameter is, for example, 1.0 to 2.0 mm. In addition, the material of the sheath is not particularly limited as long as it is steel, but it is desirable to use mild steel or low-alloy steel with good wire drawing properties. In addition, as long as each component in the welding wire is within the scope of the present invention, the flux filling rate can be set to any value, but from the viewpoint of drawability of the welding wire and operability (feedability, etc.) It is 10-25% by mass of the total mass of welding wire.

[0022] [Amount of acid-soluble Al in flux]

[0023] In the flux-cored welding wire of this embodiment, acid-soluble Al is blended in the flux. Here, the so-called "acid-soluble Al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com