Polyketone composition applied to supporting and sliding elements in architectural engineering and preparation method thereof

A sliding element and construction engineering technology, applied in the field of materials, can solve the problems of poor friction coefficient and low-temperature toughness of polyester compositions, and achieve the effects of improving bearing capacity and toughness, stabilizing friction coefficient, and improving wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

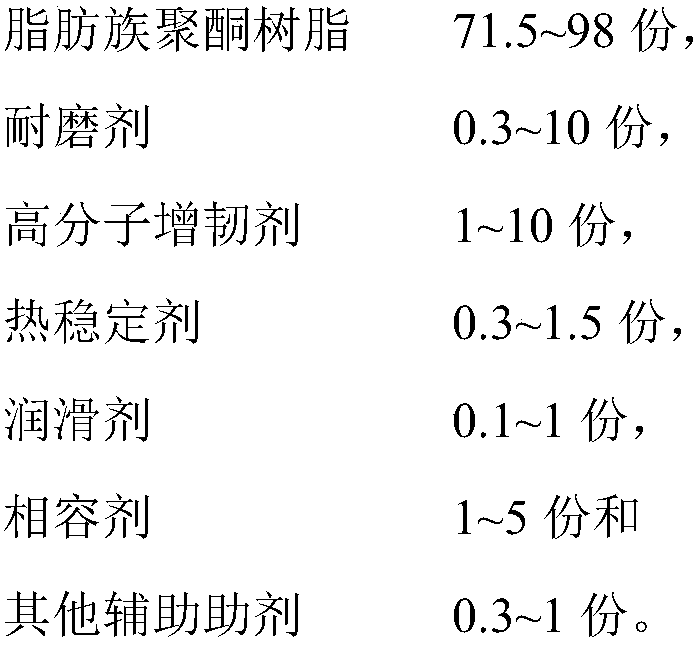

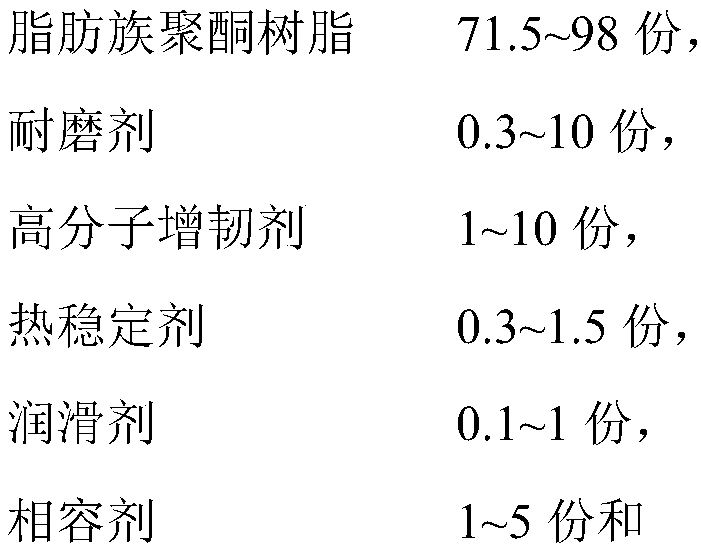

Method used

Image

Examples

Embodiment 1

[0041] A kind of polyketone composition for construction engineering supporting sliding element of the present invention, its raw material comprises each component of following mass fraction: 86.3 parts of aliphatic polyketone resins (M330A, South Korea Hyosung), 5 parts of composite wear-resistant agents ( 2 parts of silicone masterbatch MB50-001, 3 parts of Dow Corning polytetrafluoroethylene micropowder L-5, Japan Daikin), 5 parts of polymer toughening agent (polyurethane elastomer 1190A, BASF), 0.3 part of heat stabilizer (hydroxyl Apatite TGY1126, Xi’an Tianguangyuan), 1 part of lubricant (ethylene-methacrylic acid copolymer Nucrel, DuPont), 2 parts of compatibilizer (polypropylene grafted maleic anhydride HS1-009A, Guangzhou Hecheng Chemical) and 0.5 part of other auxiliary additives (0.3 part of antioxidant XL-1, Nanjing Ketura; 0.2 part of silane coupling agent KH550, Nanjing Aocheng Chemical).

[0042] The polyketone composition of the present embodiment adopts extrus...

Embodiment 2

[0047] A polyketone composition for supporting sliding elements in construction engineering of the present invention, its raw materials include the following components in parts by mass: 84.7 parts of aliphatic polyketone resin (M330A, Korea Hyosung), 3 parts of anti-wear agent (silicon Ketone masterbatch MB50-001, Dow Corning), 8.5 parts of polymer toughening agent (polyester elastomer 6356, DuPont; 0.5 parts of synergistic toughening agent AX890, Arkema), 0.3 parts of heat stabilizer (hydroxyapatite TGY1126, Xi’an Tianguangyuan), 1 part of lubricant (ethylene-methacrylic acid copolymer Nucrel, DuPont), 2 parts of compatibilizer (polypropylene grafted maleic anhydride HS1-009A, Guangzhou Hecheng Chemical) and other auxiliary aids 0.5 part of agent (0.3 part of antioxidant XL-1, Nanjing Ketura; 0.2 part of silane coupling agent KH550, Nanjing Aocheng Chemical).

[0048] The polyketone composition of the present embodiment adopts extrusion granulation-injection molding process,...

Embodiment 3

[0053] A polyketone composition for supporting sliding elements in construction engineering of the present invention, its raw materials include the following components in parts by mass: 88.2 parts of aliphatic polyketone resin (M330A, Korea Hyosung), 3 parts of composite wear-resistant agent ( 2 parts of ultra-high molecular weight polyethylene GUR4150, Ticona, USA; 1 part of nano-silicon carbide DK-SiC-001, Beijing Deke Island Gold), 5 parts of polymer toughening agent (acrylonitrile-butadiene-styrene copolymer PA763, Taiwan Chimei), 0.3 parts of heat stabilizer (hydroxyapatite TGY1126, Xi’an Tianguangyuan), 1 part of lubricant (ethylene-acrylic acid copolymer 1108C, DuPont), 2 parts of compatibilizer (polypropylene grafted horse Anhydride HS1-009A, Guangzhou Hecheng Chemical) and 0.8 parts of other auxiliary agents (0.3 parts of anti-ultraviolet agent UV1164, Hubei Jusheng Technology; 0.3 parts of antioxidant XL-1, Nanjing Kejuya; 0.2 parts of silane coupling Agent KH550, N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com