Wheat straw fiber-reinforced gangue geopolymer material and preparation method thereof

A geopolymer and fiber-reinforced technology, applied in the field of wheat straw fiber reinforced coal gangue geopolymer materials and preparation, can solve the problem of non-condensing strength of cement cementitious materials, reduce the alkalinity of cement cementitious materials, and hinder the hydration of cement particles and other problems, to achieve the effect of improving the cracking and toughening effect, slowing down the excessive consumption, and achieving significant environmental and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Implement the preparation method of the above-mentioned wheat straw fiber reinforced coal gangue geopolymer material: firstly carry out the crushing and calcination of coal gangue, then carry out the weighing, batching and mixing of materials, and finally carry out the preparation of wheat straw fiber reinforced coal gangue geopolymer material ,Specific steps are as follows;

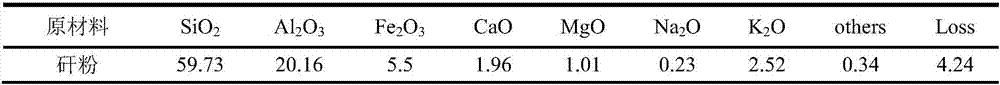

[0038] (1) Crushing and grinding the gangue to make gangue powder, then placing the gangue powder in a high-temperature furnace and calcining at a constant temperature of 700°C-900°C for 0.5 hours to obtain the gangue powder; the gangue powder is The solid waste discharged during coal mining and coal washing is made by drying, crushing, grinding and calcination, and the grinding makes it reach a specific surface area of ≥350m 2 / kg, coal gangue particles with a particle size of less than 30 μm accounted for more than 90% of the total mass.

[0039] (2) Weigh the gangue powder, wheat straw fiber...

Embodiment 1

[0044] The preparation method of wheat straw fiber reinforced coal gangue geopolymer material, the composition and mass percentage of coal gangue geopolymer material are as follows: gangue powder 56.7%; mineral powder 40%; slaked lime 2.2%; wheat straw fiber 1% (accounting for powder body material); sodium silicate activator 26.7% (accounting for powder material by mass); NaOH 5.3% (accounting for powder material); water 26.7% (accounting for powder material).

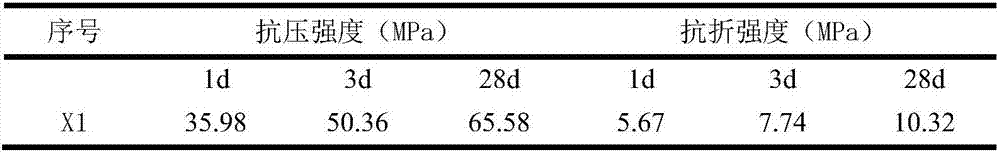

[0045] Table 3 test mix ratio g

[0046]

[0047] First, the crushing and calcination of coal gangue are carried out, then the weighing, batching and mixing of materials are carried out, and finally the preparation of wheat straw fiber reinforced coal gangue geopolymer material is carried out;

[0048] (1) Crushing and grinding the gangue to make gangue powder, then placing the gangue powder in a high-temperature furnace and calcining at a constant temperature of 700°C-900°C for 0.5 hours to obtain gangue powder;

...

Embodiment 2

[0053] Embodiment 2: preparation method is identical with embodiment 1, omission. The difference is that the composition and mass percentage of the coal gangue geopolymer material are as follows: gangue powder 66.8%; mineral powder 30%; slaked lime 2.2%; wheat straw fiber 1% (accounting for powder material); Activator 26.7% (accounting for powder material by mass); NaOH 5.3% (accounting for powder material); water 26.7% (accounting for powder material).

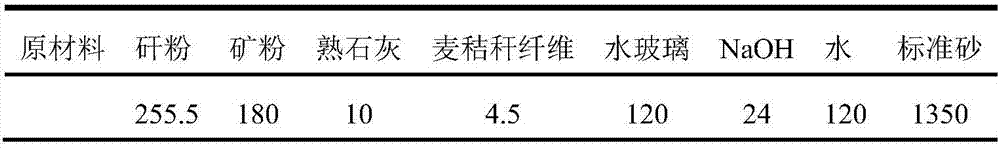

[0054] Table 4 test mix ratio g

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com