Building sealant and preparation method thereof

A technology of beautiful sewing and construction, applied in the direction of adhesives, adhesive types, polyether adhesives, etc., can solve problems such as mildew, toxic curing agents, and failure to achieve noble, elegant, warm and luxurious decoration effects, etc., to prevent air pollution Drumming and loosening, brick seam and brick surface flush, bright and delicate color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

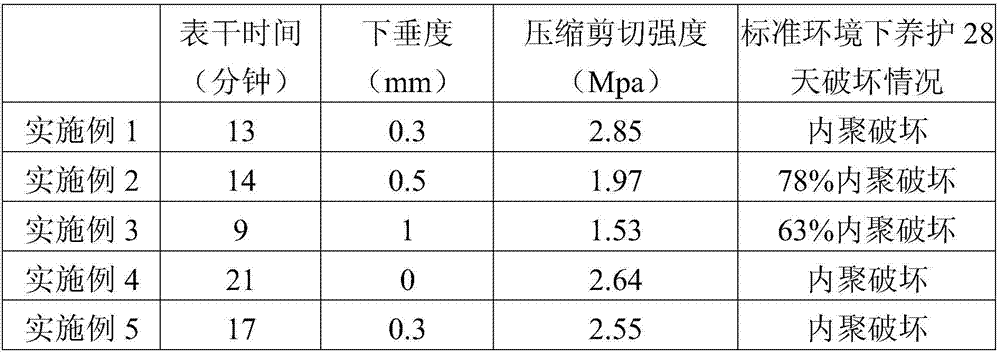

Examples

no. 1 example

[0026] According to the ratio of mass components, the building joint glue includes 100 parts of hybrid resin, 3 parts of plasticizer, 200 parts of calcium carbonate, 0.5 parts of ultraviolet absorber, 3 parts of silane coupling agent, 3 parts of silane crosslinking agent and 0.8 parts of catalyst share.

[0027] Furthermore, the hybrid resin is terminated by siloxane, the main chain is polyether molecular structure, the structural formula is: (RO)3SiO[(CH2)3O]nSi(RO)3, where R is C1-C2 base, n is the number of repeating units in the main chain.

[0028] Furthermore, calcium carbonate is one or more mixtures of nano-scale calcium carbonate, heavy calcium, silicon micropowder, and talcum powder kaolin whose surface has been treated with fatty acid or stearic acid.

[0029] Further, the plasticizer is polyethylene glycol with a molecular weight of 800; the ultraviolet absorber UV-328; the silane coupling agent is methyltriethoxysilane; the silane crosslinking agent is γ-aminopro...

no. 2 example

[0035] According to the ratio of mass components, the building seam glue includes 100 parts of hybrid resin, 10 parts of plasticizer, 260 parts of calcium carbonate, 1 part of ultraviolet absorber, 5 parts of silane coupling agent, 6 parts of silane crosslinking agent and 1 part of catalyst share.

[0036] Further, the plasticizer is polytetrahydrofuran glycol, the molecular weight is 2000; the ultraviolet absorber is UV-326; the silane coupling agent is vinyltrimethoxysilane; the silane crosslinking agent is N-(β-ammonia Ethyl)-γ-aminopropylmethyldimethoxysilane; the catalyst is stannous octoate.

[0037] Its preparation method comprises the following steps:

[0038] (1) Add the hybrid resin, part of vinyltrimethoxysilane, polytetrahydrofuran glycol, UV-326 and nano-calcium carbonate into the double planetary power mixer in batches and stir at high speed, and dehydrate under the vacuum degree of 0.099Mpa 1.5 hours, the speed is 1000rpm;

[0039] (2) Add the remaining vinyl...

no. 3 example

[0043] According to the ratio of mass components, the building seam glue includes 100 parts of hybrid resin, 16 parts of plasticizer, 280 parts of calcium carbonate, 1.2 parts of ultraviolet absorber, 7 parts of silane coupling agent, 9 parts of silane crosslinking agent and 1.2 parts of catalyst share.

[0044] Further, the plasticizer is diisononyl phthalate; the ultraviolet absorber is UV-3583; the silane coupling agent is vinyltriethoxysilane; the silane crosslinking agent is ureidopropyltrimethoxysilane ; The catalyst is dibutyltin diacetate.

[0045] Its preparation method comprises the following steps:

[0046] (1) Add the hybrid resin, part of vinyltriethoxysilane, diisononyl phthalate, UV-3583 and calcium carbonate into the double planetary power mixer in batches and stir at high speed, and the vacuum degree is 0.099Mpa Dehydration for 2 hours, the speed is 900rpm;

[0047](2) Add the remaining vinyltriethoxysilane into the mixing tank of the planetary machine, sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com