Terminal-modified soluble polyfunctional vinyl aromatic copolymer, and curable resin composition and optical waveguide produced using same

A vinyl aromatic and aromatic compound technology, applied in synthetic resin layered products, optical waveguide light guides, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0391] Hereinafter, although an Example demonstrates this invention concretely, this invention is not limited to these Examples. In addition, the part in each example is a weight part, and the measurement of a physical property was performed by the method shown below.

[0392] 1) Molecular weight and molecular weight distribution of the copolymer (soluble polyfunctional aromatic copolymer)

[0393] Molecular weight and molecular weight distribution were measured using a gel permeation chromatograph (Gel Permeation Chromatograph, GPC) (manufactured by Tosoh, HLC-8120GPC), using tetrahydrofuran as a solvent, with a flow rate of 1.0ml / min and a column temperature of 38°C, using a single Calibration curves for dispersed polystyrene were performed.

[0394] 2) The structure of the copolymer

[0395] Using the JNM-LA600 nuclear magnetic resonance spectrometer manufactured by JEOL, using 13 C-Nuclear Magnetic Resonance (NMR) and 1 H-NMR analysis to determine. use chloroform-d 1...

Synthetic example 1

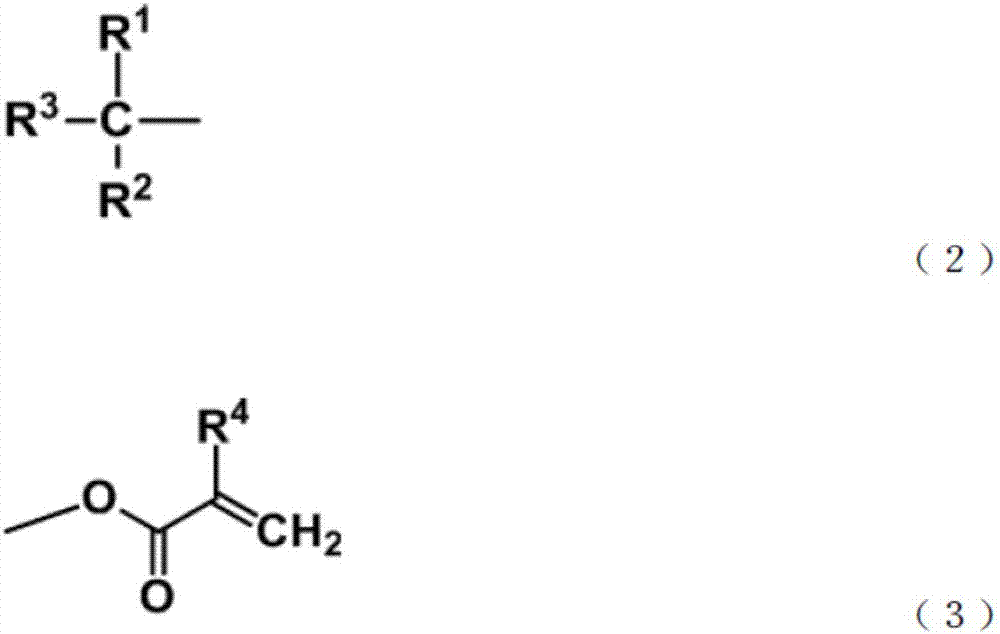

[0406] 1.28 moles (182.7 mL) of divinylbenzene (a mixture of 1,4-divinylbenzene and 1,3-divinylbenzene, the same applies to the following examples), ethylvinylbenzene (1-ethyl- A mixture of 4-vinylbenzene and 1-ethyl-3-vinylbenzene (the same applies to the following examples) 0.97 moles (137.8 mL), 2.00 moles (323.2 mL) of tert-butyl methacrylate, and 300 mL of toluene were added to 2.0 In the reactor of L, 50 millimoles of boron trifluoride diethyl ether complexes were added at 50 degreeC, and it reacted for 4 hours. After stopping the polymerization with an aqueous sodium bicarbonate solution, the oil layer was washed three times with pure water, devolatilized under reduced pressure at 60° C., and a polymer was recovered. The obtained polymer was weighed, and it was confirmed that 234.6 g of copolymer A was obtained.

[0407] Mn of the obtained copolymer A was 842, Mw was 3640, and Mw / Mn was 4.32. by carrying out 13 C-NMR and 1 In H-NMR analysis, resonance lines derived ...

Synthetic example 2

[0411] Put 1.28 moles (182.7 mL) of divinylbenzene, 0.97 moles (137.8 mL) of ethyl vinylbenzene, 2.00 moles (289.6 mL) of tert-butyl acrylate, and 300 mL of toluene into a 2.0 L reactor. 50 mmol of boron trifluoride diethyl ether complex was added, and the reaction was performed for 4 hours. After stopping the polymerization with an aqueous sodium bicarbonate solution, the oil layer was washed three times with pure water, devolatilized under reduced pressure at 60° C., and a polymer was recovered. The obtained polymer was weighed, and it was confirmed that 215.3 g of copolymer B was obtained.

[0412] Mn of the obtained copolymer B was 952, Mw was 4490, and Mw / Mn was 4.72. by carrying out 13 C-NMR and 1 In H-NMR analysis, resonance lines derived from terminal groups of tert-butyl acrylate were observed in copolymer B. The introduced amount (c1) of structural units derived from tert-butyl acrylate in the soluble polyfunctional vinyl aromatic polymer calculated from the elem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com